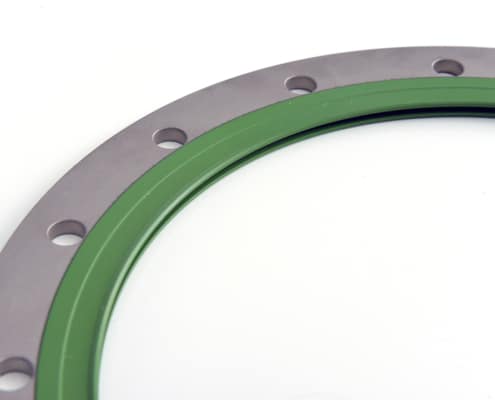

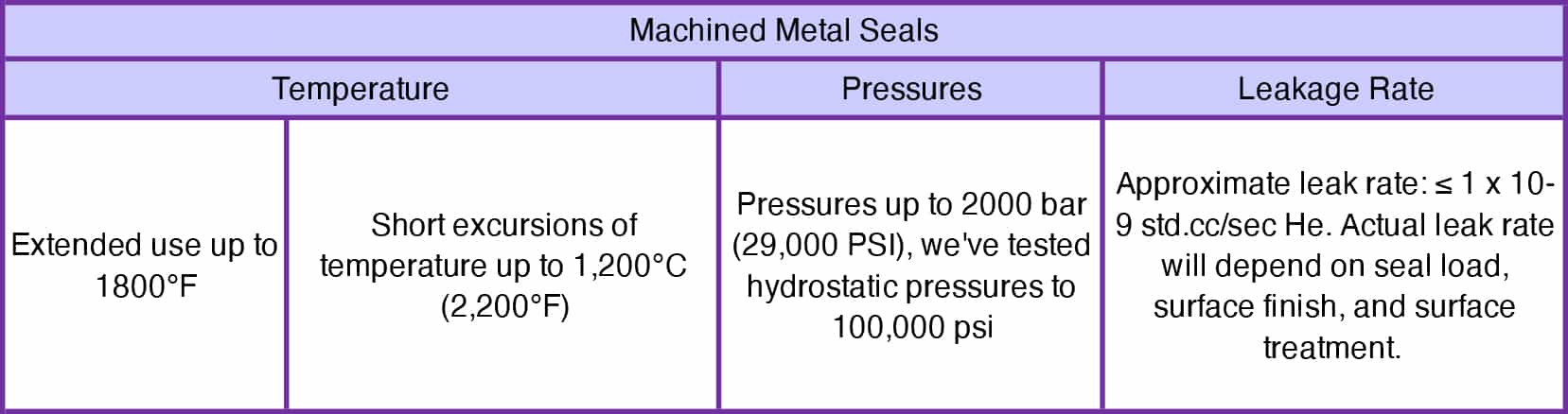

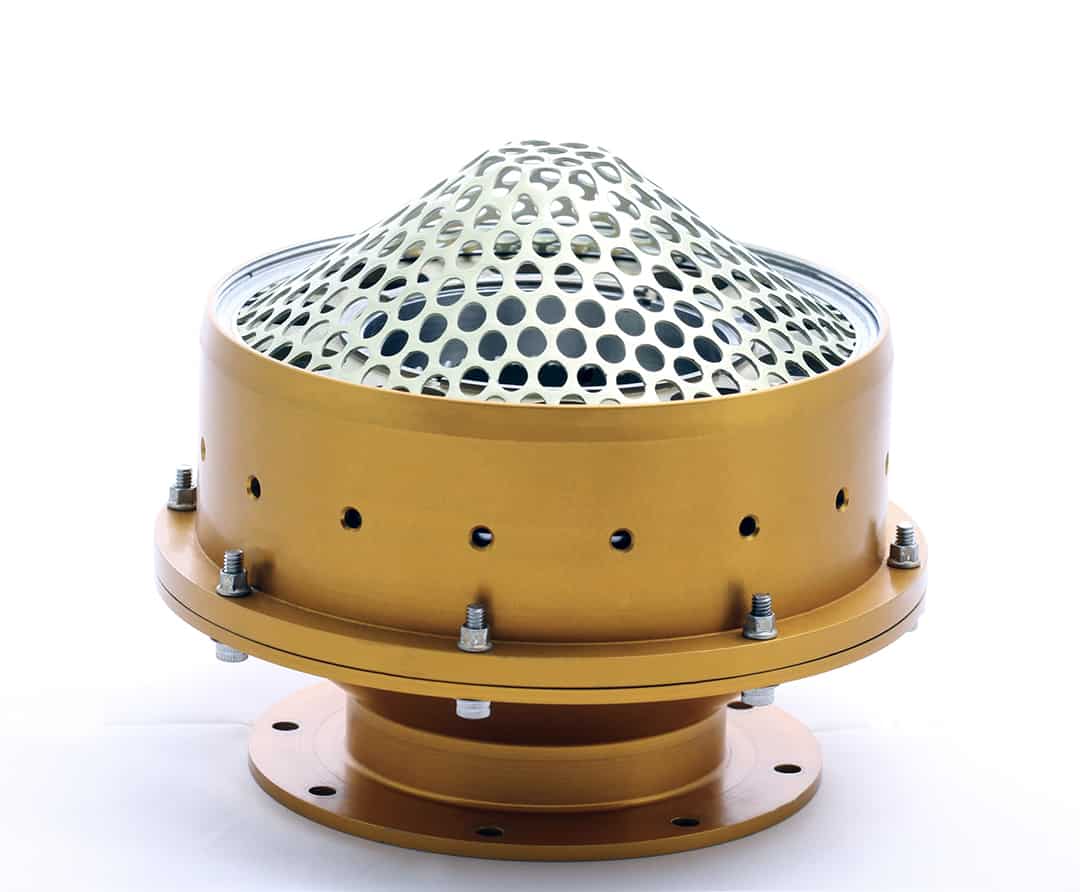

Machined Metal Seals

Technetics offers a diverse range of machined metal sealing solutions for extremely demanding environments. We can design and manufacture from any machinable material at our state-of-the-art manufacturing facilities that are equipped with machining centers and coordinated measurement systems to ensure world quality precision.

Features & Benefits

Benefits:

Machined metal seals are designed to meet applications with high temperatures or cryogenics, high pressures, full vacuum, very corrosive chemicals and penetrating levels of radiation.

Unlike formed metal sealing solutions, machined seals do not require tooling to be developed, reducing this associated cost and lead-time.

During rapid development, programming for machining for modified parameters requires much less time than tooling modifications required for formed seal solutions.

Suitable for applications that require a metal seal that is difficult to manufacture in certain sizes or require a special geometry profile.

Features:

- Platings and coatings: silver, gold, nickel, PTFE

- Extremely corrosive and radioactive environments

-

Pressure up to 241 bar (3,495 PSI)

-

Temperature up to 1,200°C (2,200°F)

- Suitable for applications that require a metal seal that is difficult to manufacture in certain sizes or require a special geometry profile

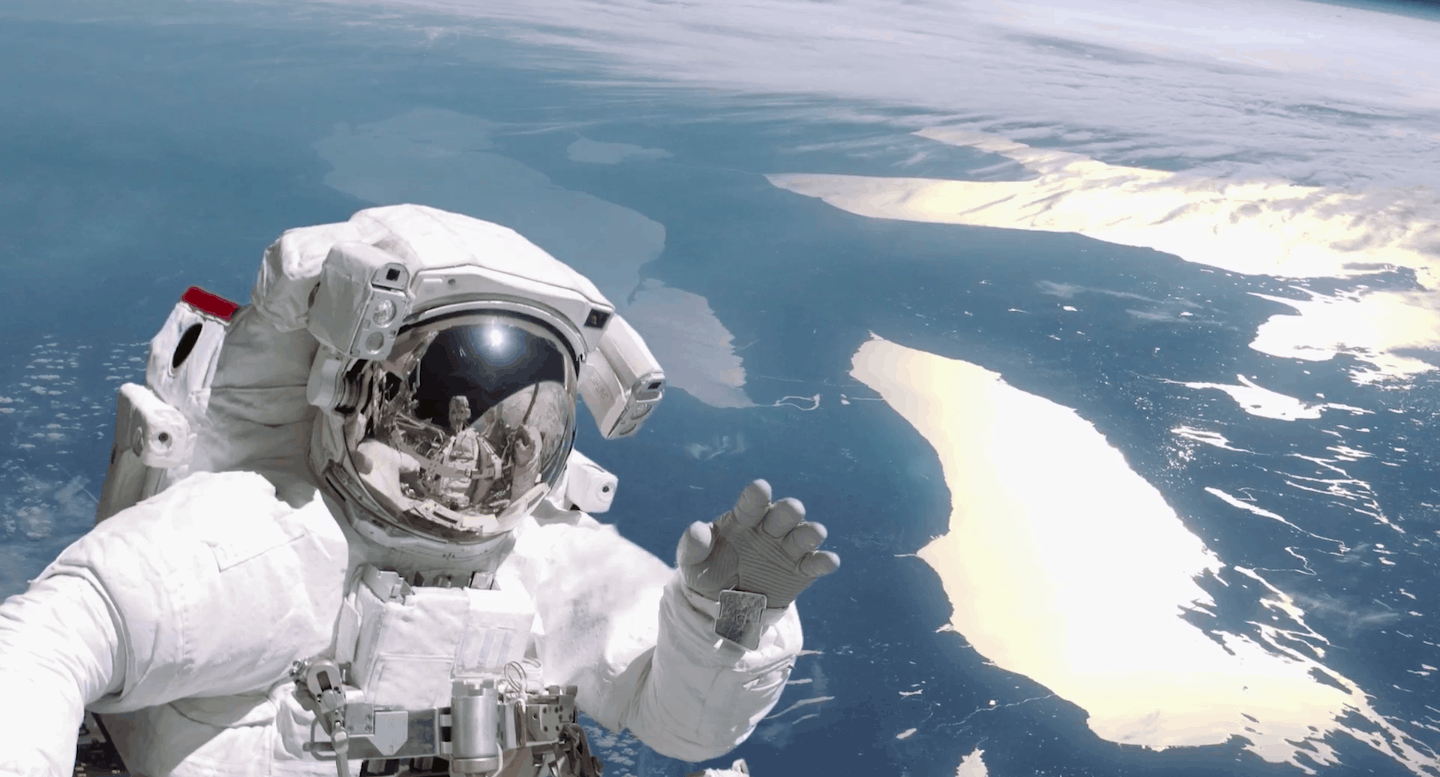

Product Applications

- Aerospace Industry

- Space Launch System (SLS) – Technetics provides Boeing with NAFLEX and K-Port seals for SLS liquid hydrogen fuel and liquid oxygen propellant bolted joints and AS5202 threaded ports. The NAFLEX seals ensure the integrity of critical fluid connections during the stress of launch during extremes of high and low temperatures during the mission.

- Space Shuttle

- Aerojet Rocketdyne RL10 and RS-25 Engines

- Chemical Processing

- Construction

- Industrial Industry

- Industrial Turbines

- Flow Control

- Life Sciences

- New Energies

- Nuclear Industry

- Oil & Gas

- Pumps

- Semiconductors

- Sensors

- Valves