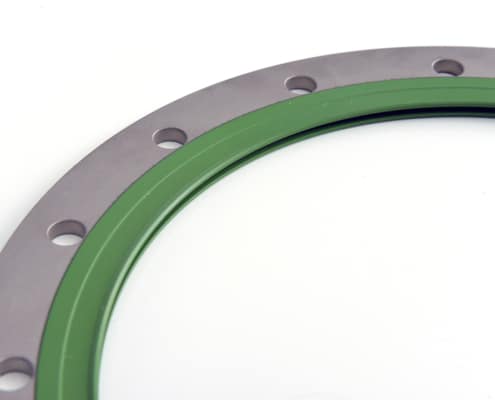

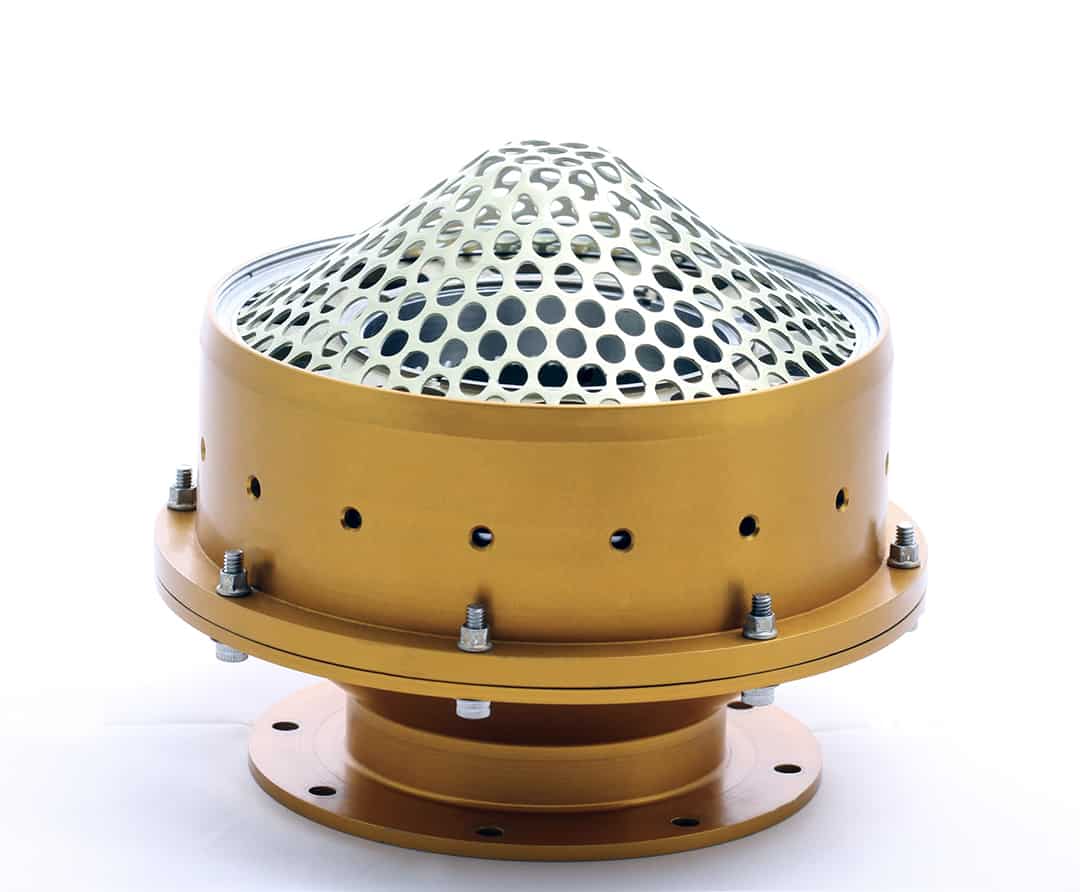

기계가공 메탈씰

테크네틱스는 극도로 까다로운 환경을 위한 다양한 가공 금속 씰링 솔루션을 제공합니다. 당사는 머시닝 센터와 조정된 측정 시스템을 갖춘 최첨단 제조 시설에서 가공 가능한 모든 재료로 설계 및 제조하여 세계 최고의 품질 정밀도를 보장합니다.

특징과 우수성

혜택:

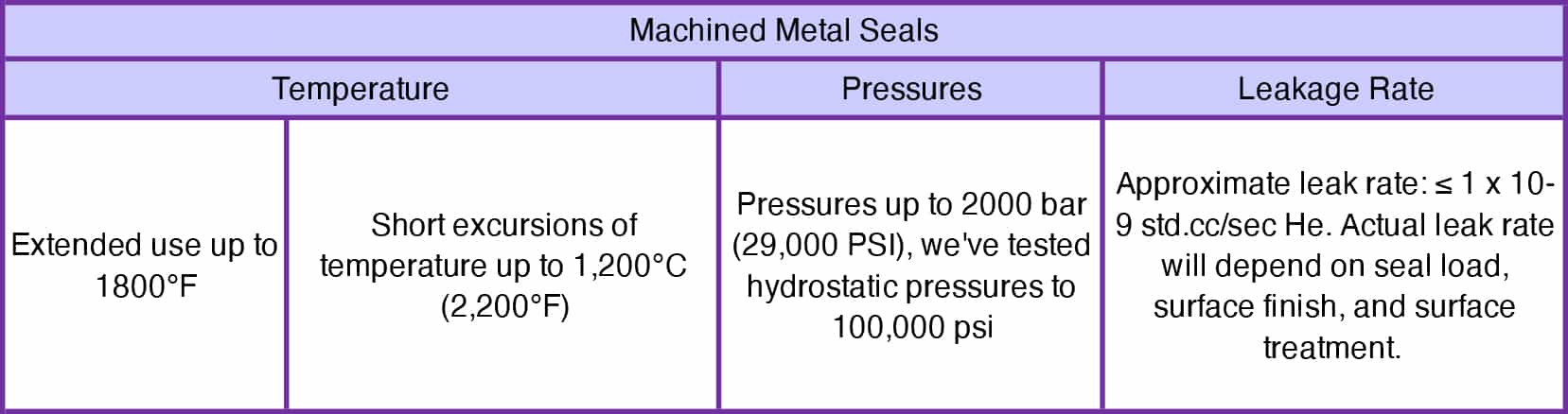

가공 금속 씰은 고온 또는 극저온, 고압, 완전 진공, 부식성이 강한 화학 물질 및 방사선을 투과하는 애플리케이션을 충족하도록 설계되었습니다.

성형 금속 씰링 솔루션과 달리 가공 씰은 툴링을 개발할 필요가 없으므로 관련 비용과 리드 타임이 줄어듭니다.

신속한 개발 과정에서 수정된 파라미터에 대한 가공 프로그래밍은 성형된 씰 솔루션에 필요한 툴링 수정보다 훨씬 적은 시간이 소요됩니다.

특정 크기로 제조하기 어렵거나 특수한 형상 프로파일이 필요한 금속 씰이 필요한 애플리케이션에 적합합니다.

기능:

- 도금 및 코팅: 은, 금, 니켈, PTFE

- 극심한 부식성 및 방사능 환경

-

최대 241bar(3,495PSI)의 압력

-

최대 1,200°C(2,200°F)까지 온도 조절 가능

- 특정 크기로 제조하기 어렵거나 특수한 형상 프로파일이 필요한 금속 씰이 필요한 애플리케이션에 적합합니다.

제품 적용

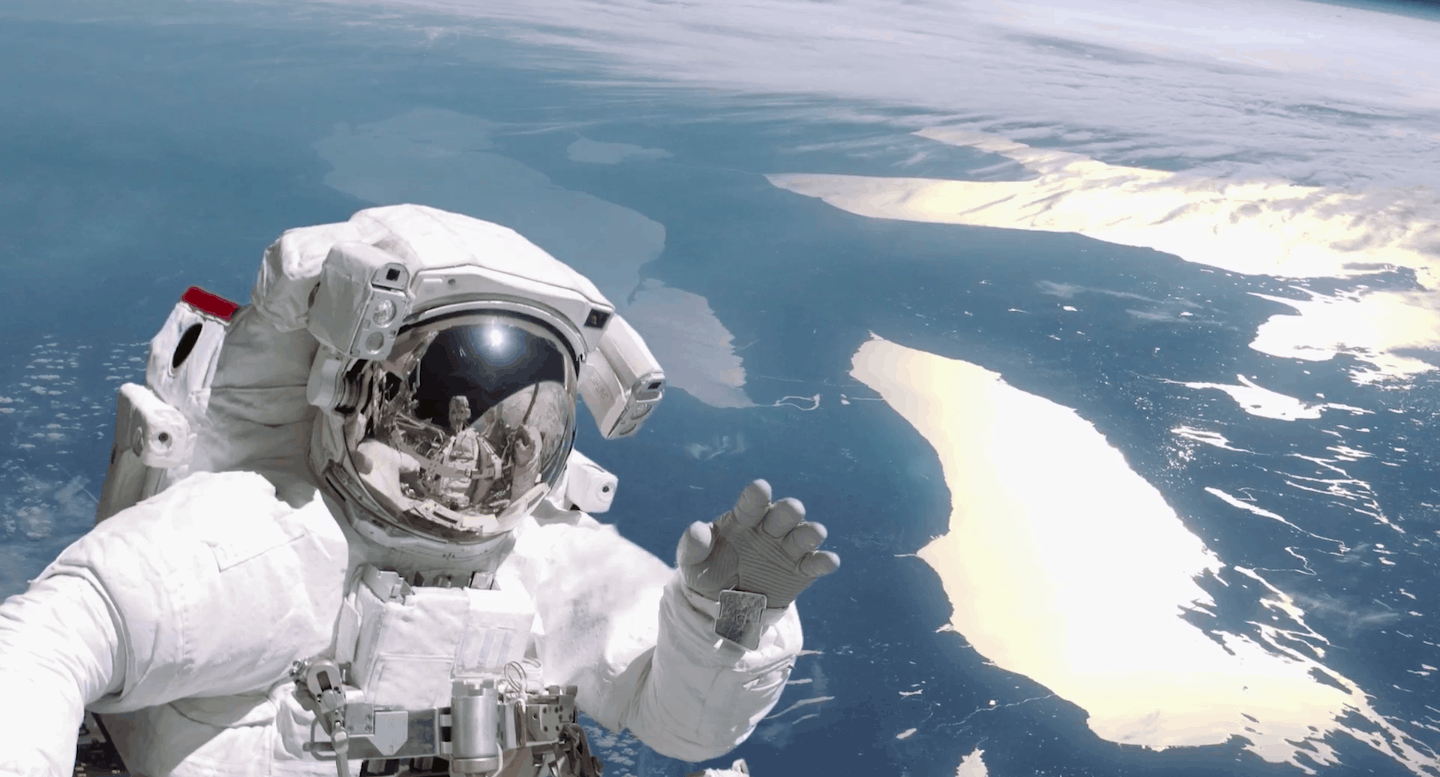

- 항공 우주 산업

- 우주 발사 시스템(SLS) - 테크네틱스는 보잉에 SLS 액체 수소 연료 및 액체 산소 추진제 볼트 조인트와 AS5202 나사산 포트용 NAFLEX 및 K-포트 씰을 공급합니다. NAFLEX 씰은 임무 수행 중 극한의 고온 및 저온에서 발사 스트레스를 받는 동안 중요한 유체 연결의 무결성을 보장합니다.

- 우주 왕복선

- 에어로젯 로켓다인 RL10 및 RS-25 엔진

- 케미칼 프로세싱

- 건설

- 산업 산업

- 산업용 터빈

- 유체 제어

- 생명 과학

- 신재생 에너지

- 원자력 산업

- 오일 및 가스

- 펌프

- 반도체

- 센서

- 밸브