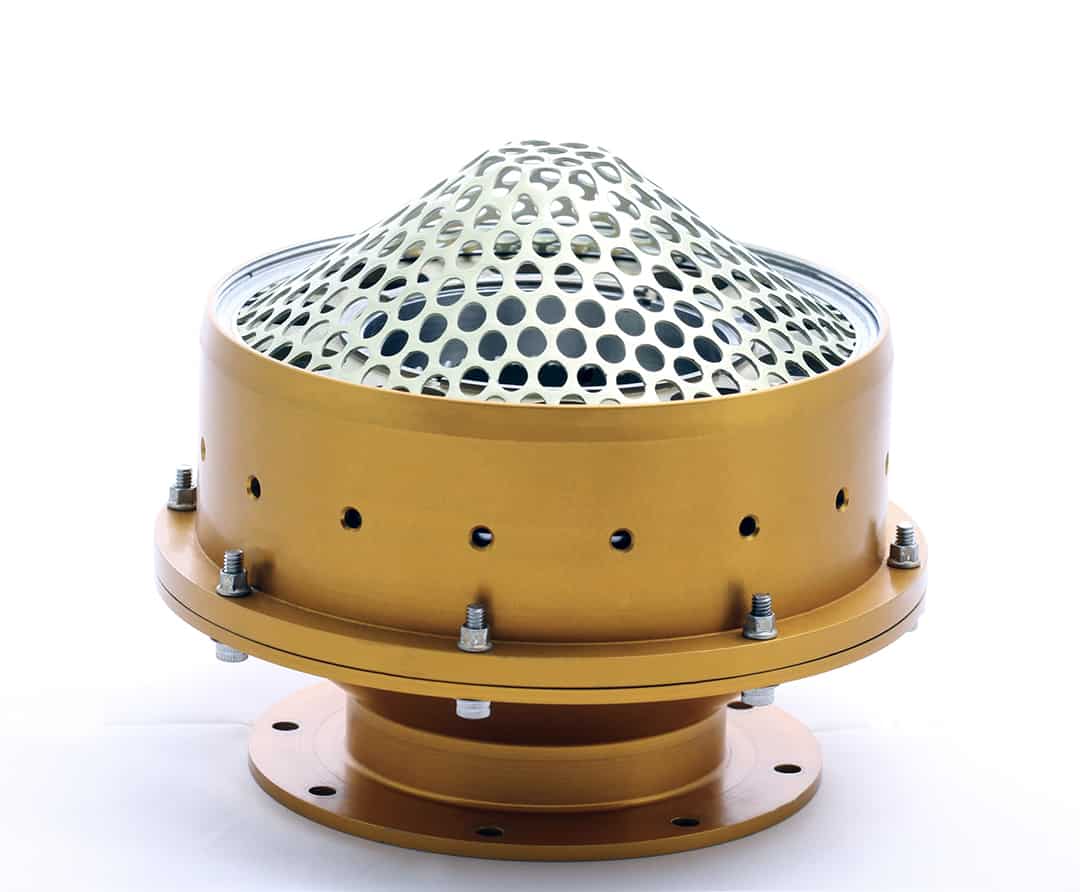

Rupture Disc – SAFE-SHEAR™ Belleville Burst Disc

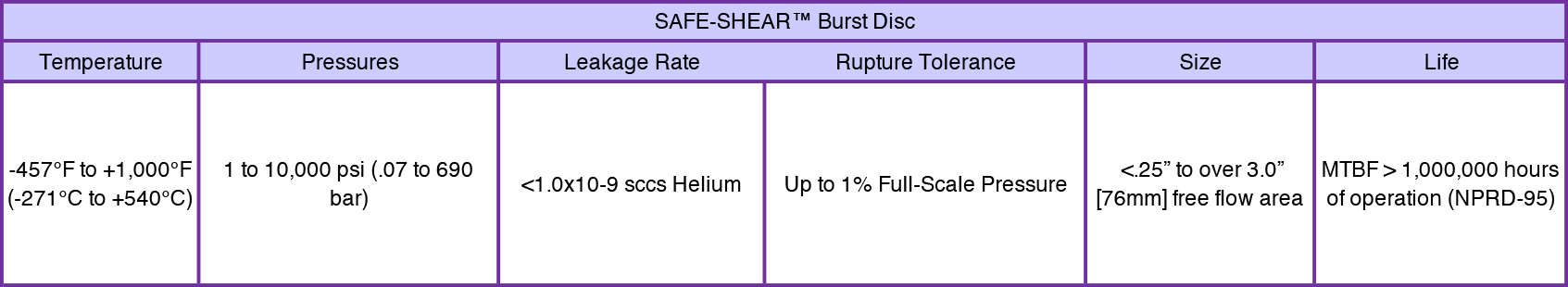

Technetics Group will design, manufacture, and test a precision burst disc assembly for your application. Our burst discs are capable of precise and reliable burst settings from low pressures or vacuum (1 psi pressure differential), up to 10,000 psi. All this while maintaining up to 1% full-scale precision and infinitesimal leakage, regardless of infinite pressure and temperature cycles, dynamic environments, and harsh media.

Precision Burst Discs

The SAFE-SHEAR™ Burst Disc is designed to set and verify exact rupture pressure in a non-destructive test.

The BELLEVILLE spring snap-over trigger mechanism relies on a proprietary solution to achieve extreme accuracy. Diaphragm thickness resists 2 to 3 times the burst set pressure, and is capable of infinite cycling without degradation to fatigue. Cycling may be up to 98% of set burst pressure without altering performance.

It has been demonstrated that Belleville type burst discs are one order of magnitude more accurate than Frangible type burst discs.

Features & Benefits

Features:

- Materials: Aluminum, Stainless, Titanium, Inconels & Superalloys, PTFE

- Media: Compatible With Jet & Rocket Fuels, Oxidizers, other Harsh Fluids

- Mounting: Flange, weld to tube, AS5202 threaded, custom

- Reverse Pressure Protection: full reverse, cycling

- Shock: Pyrotechnic, Operational & Crash Safety (call for details)

- Vibration: Launch, Abort, Ground, Runway, high to low frequency (call for details)

- Mass: Variable, based on usage

- Tested millions of cycles without failure or setting creep, up to 95% of the rupture

- Qualification: Units have been tested and qualified to various RTCA DO-160, MIL requirements

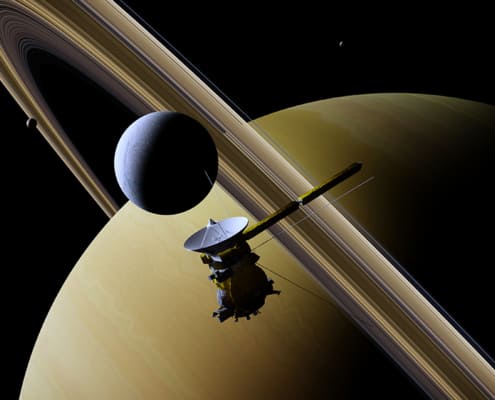

Aerospace Applications

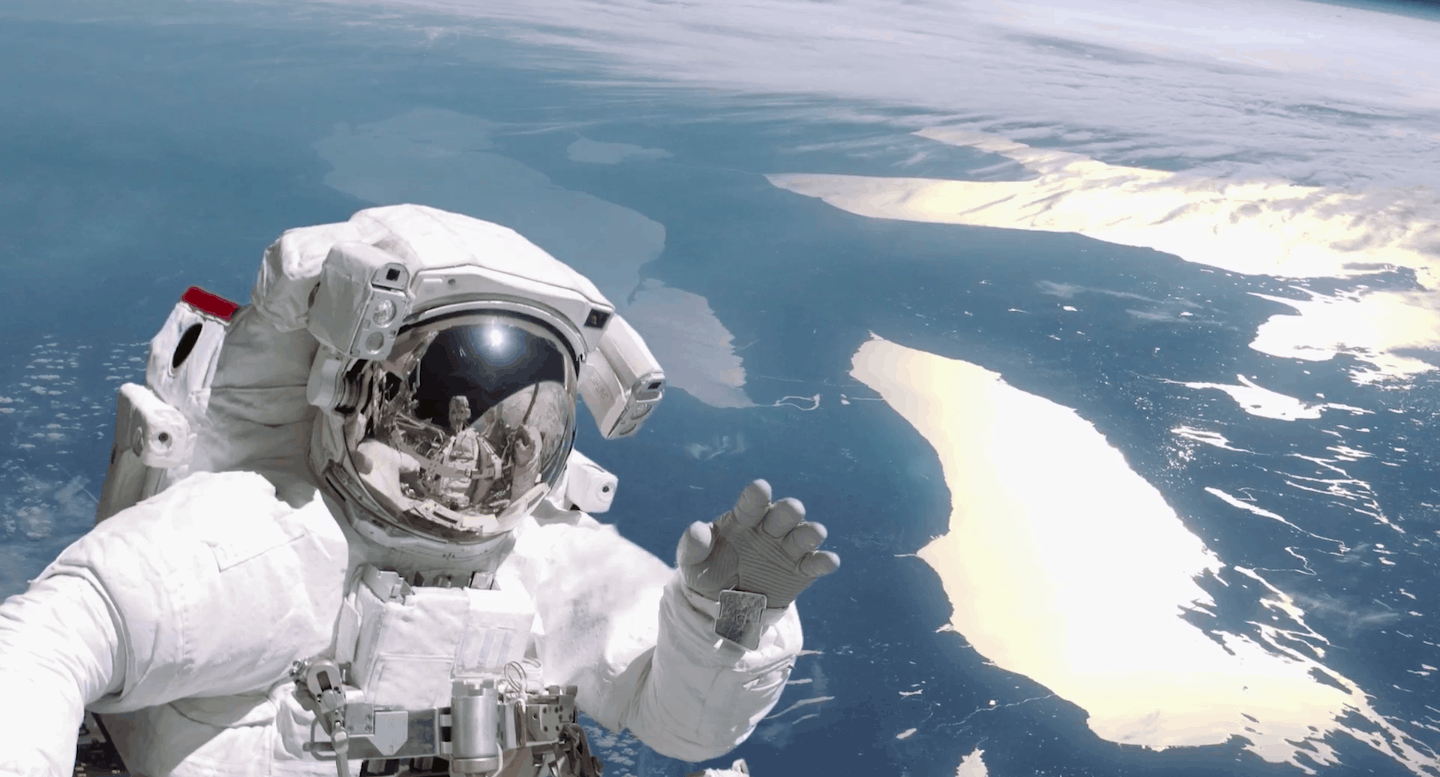

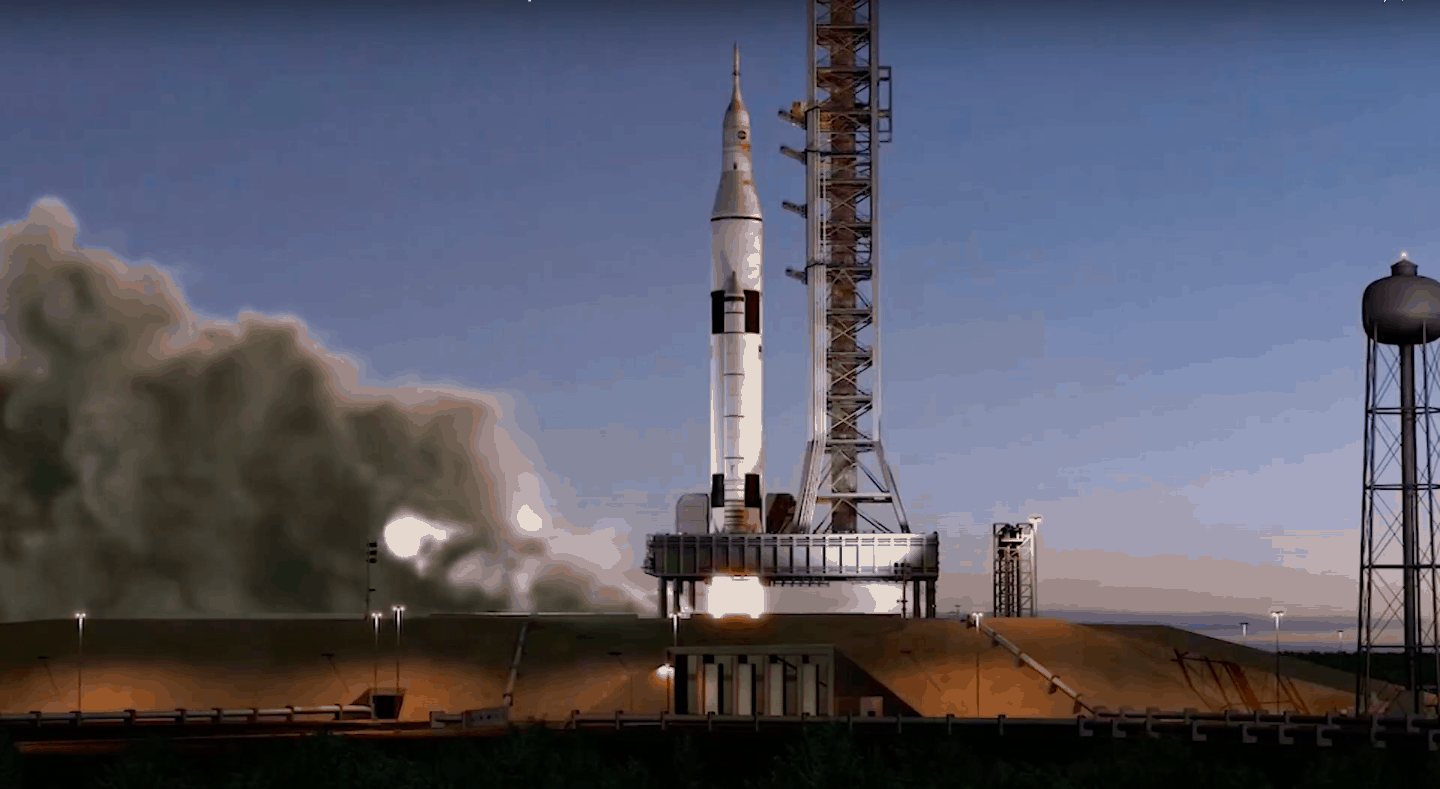

- Human Spaceflight | International Space Station & Orion

- Pedigree | Cassini Spacecraft, Mars Global Surveyor, Hubble Space Telescope, Gravity Probe B, Spitzer Space Telescope, Wide-Field Infrared Survey Explorer, Bell Boeing V-22 Osprey, Embraer KC-390 Millennium

- Orbital Cryogenic Propellant Refueling | NASA ISS RRM3

- Cryogenic Fluid Management

- LH2 | −253 °C (−423.4 °F; 20.1 K)

- LOx Oxidizer | −183 °C (−297.4 °F; 90.1 K)

- Xenon Coolant | -271 °C (-456 °F; 1.8 K) , Methane, etc.

- Boil-off / Leakage less than 1.00×10-9 standard cubic centimeters per second (sccs)

- Liquid Fuel Management

- RP-1 Kerosene, Hydrazine Nitrogen Tetroxide (NTO)

- Jet Fuels