Get the Latest News and Updates

©2024 Technetics Group. All Rights Reserved. Technetics Group is an EnPro Industries, Inc. (NYSE: NPO) Company

From bridges to pipelines, skyscrapers to dams, our sealing solutions are found in some of the most demanding construction and infrastructure applications in the world.

Built to last to outperform expectations, our innovative construction technologies deliver unparalleled safety and reliability through the most extreme weather, loads and shocks.

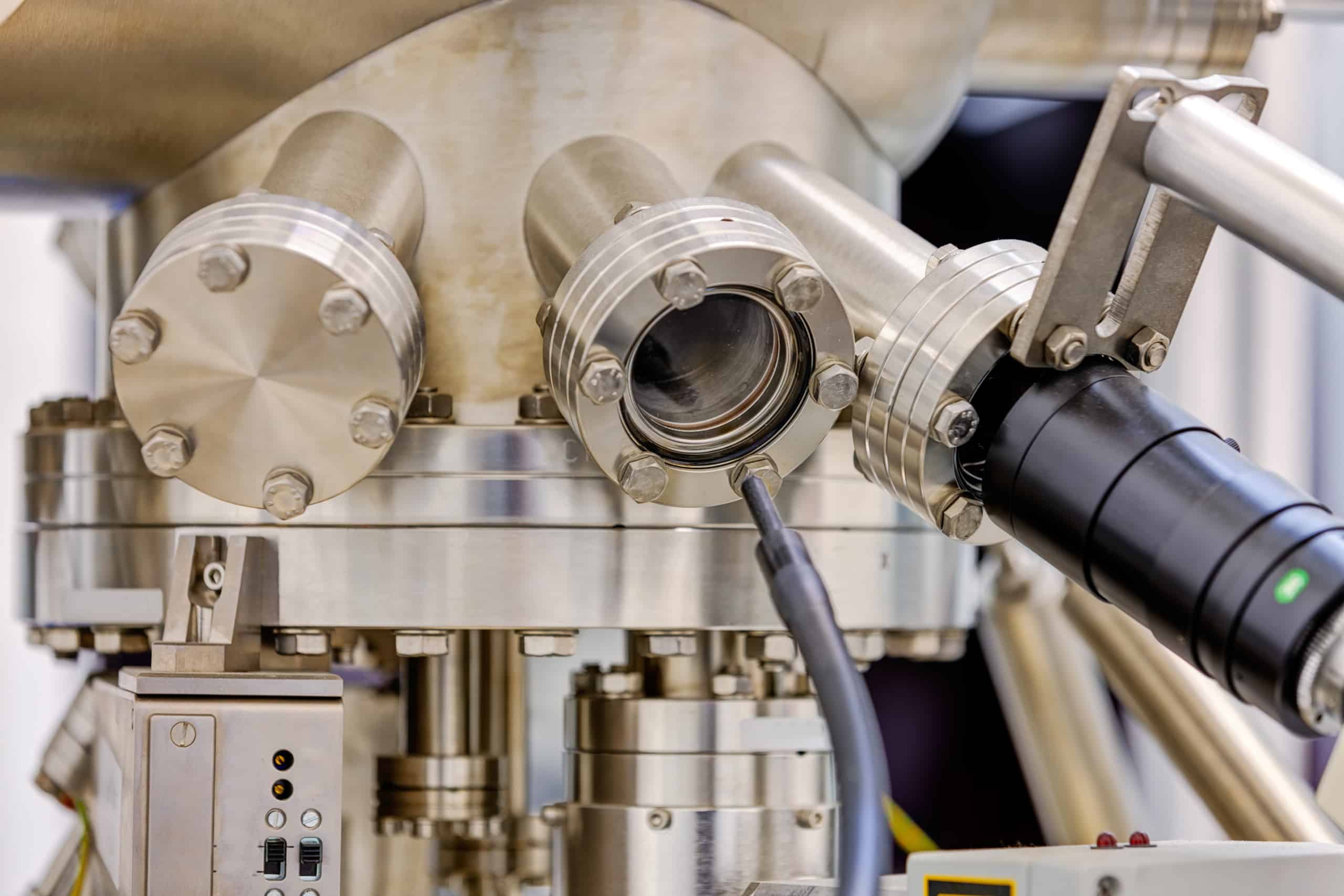

CEFIL’AIR® inflatable seals solve issues in highly critical construction projects. They have been used to reduce flooding in subway or laguna level sites. They enable the extension of construction work through dry dock creation for deep-sea harbors.

Today, with 13 primary manufacturing locations and more than 1,000 employees globally, the Technetics Group has grown to be the leading manufacturer and designer of sealing and critical component solutions, including sub-systems and assemblies, in the world.

©2024 Technetics Group. All Rights Reserved. Technetics Group is an EnPro Industries, Inc. (NYSE: NPO) Company