DEMO Fusion Reactor Case Study

Technetics’ Seals and Maintenance Expertise Propels DEMOnstration Fusion Power Plant Forward

The next-generation DEMOnstration power plant, or DEMO, is “an industry- and technology-driven program, a key criterion for DEMO is the production of electricity,” according to its designers.

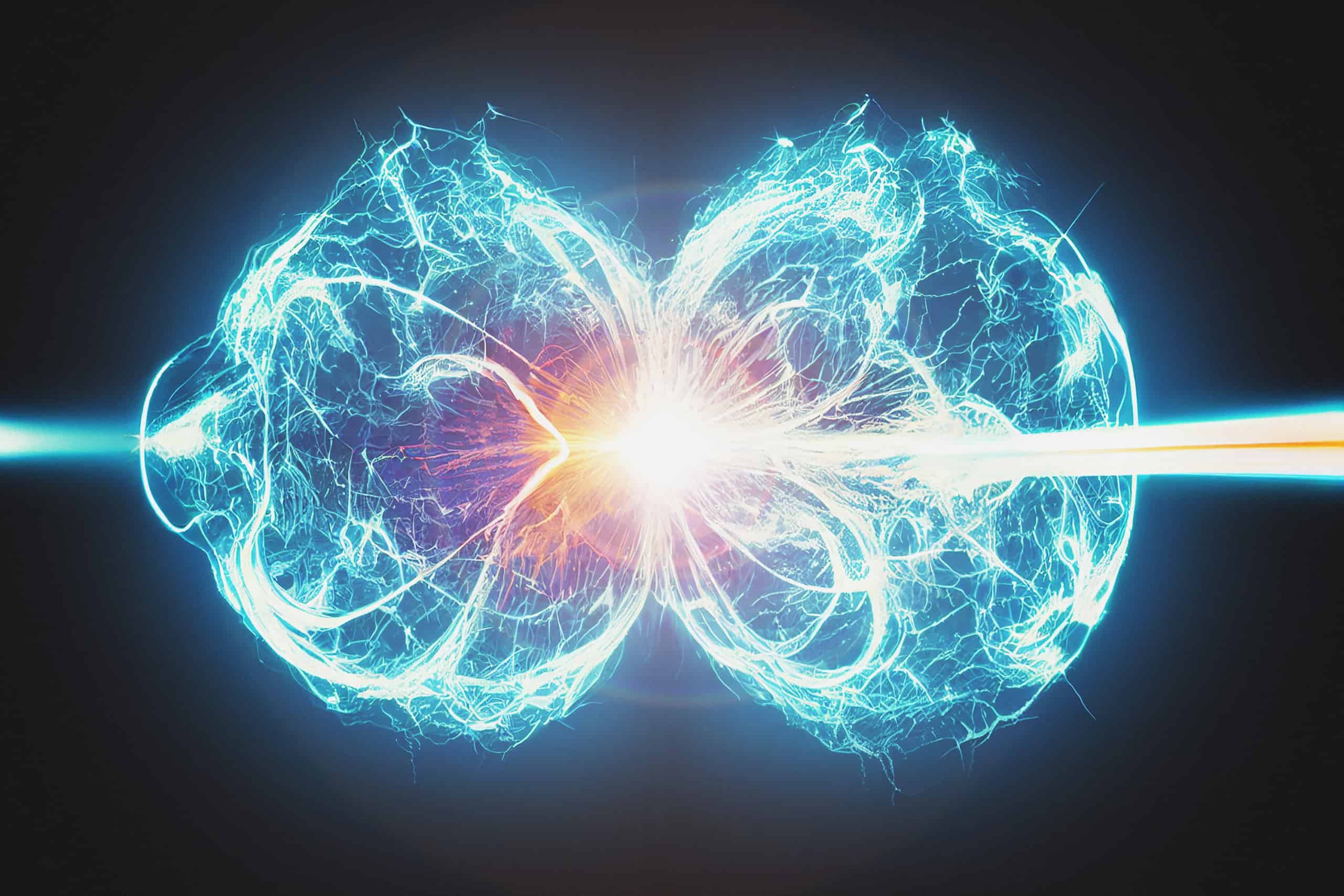

Our client approached Technetics to develop a seal and optimized assembly concept for a maintenance plan to manage the Tokamak port cells for their DEMO fusion reactor. This is no small feat as the seal’s performance is required to:

- contain the plasma at high temperatures,

- maintain a significant enough density of reacting ions,

- capture high-energy neutrons from the reaction without melting the reactor walls,

- ensure efficient operation of the plant through the prevention of pressurized steam loss, and

- protect the plant against corrosion caused by extreme temperatures inside the reactor core.

Failure is not an option as it would result in the escape of radioactive materials — causing negative consequences to human health and the environment — and an unstable reactor core, which would cause substantial damage to the Tokamak’s walls.

Clearly, the client needs industry-leading experts, and Technetics is up for the challenge.

Excelling the Future of Energy Through Technetics’ Advanced Sealing Technology

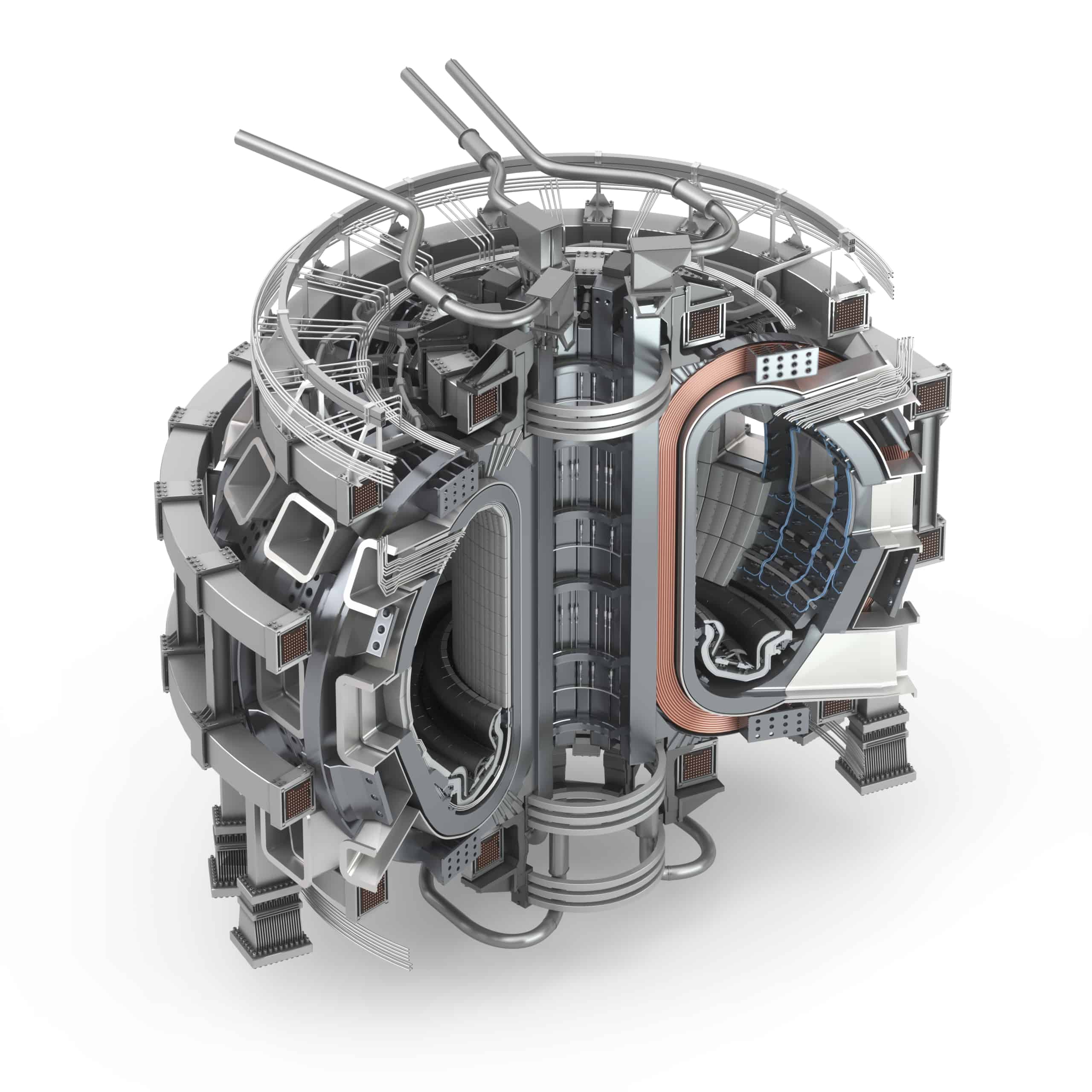

Port cells serve as confinement barriers to shield the environment from radiation generated by the reactor. The cells, made of specially formulated concrete, oppose the passage of neutrons and contamination. As important as it is to keep the radiation confined, it’s equally essential that the port cells are accessible to allow maintenance and repairs of the interior reactor.

Thanks to collaboration with the CEA, Technetics is working to solve these demanding technical challenges to enhance the project’s performance and longevity in many ways. For instance, Technetics provides various engineering solutions to develop and maintain vacuum chamber sealing as well as designing and developing specific components for the reactor, such as vacuum seals.

We steadily provide ultra-high vacuum, irradiation, tritium environment, and remote handling solutions throughout the program. Our engineers develop safety systems, cycle systems, and maintenance services to ensure the solutions are performing correctly. Additionally, we are committed to a complete, all-around engineering study and analysis for the four years of the program.

Technetics Provides Clients with Reliable Sealing Solution

Technetics delivers our premier sealing service to the technological innovations involved in our client’s new DEMO Power Plant. This project requires the best hands to gather top-quality technologies to develop a ground-breaking fusion reactor, and we deliver our seals and maintenance for the Tokamak port cells.

Now, our client has a safe and efficient DEMO fusion reactor, allowing them to focus on the primary goal of the technology: producing electricity.

At Technetics, we welcome challenging projects and enjoy finding solutions to meet our customers’ needs. Ready to start your partnership? Contact us today.