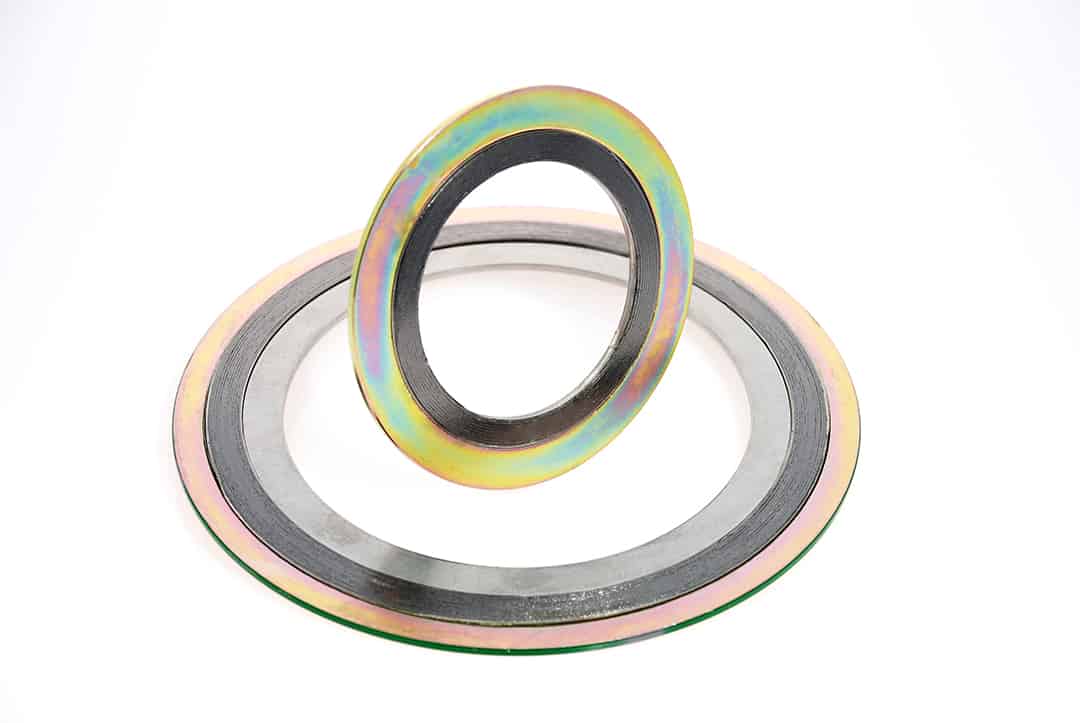

When companies need confidence in their most critical applications, they rely on Technetics Group, and our VITAFLEX® spiral wound gaskets. We have produced spiral wound gaskets for more than 30 years, honing our production techniques and materials so they can be used in a wide range of industries. We are able to meet our clients’ specific requirements including operating conditions, sealing, dimensioning of assemblies and safety level.

About Technetics Group Spiral Wound Gaskets

Spiral wound gaskets consist of a formed metal strip wound with soft filler material. The soft filler forms the seal material, which is chosen to best eliminate leakage of pressure, temperature air or fluids for the application. The metal strip is then welded into the ends of the winding to maintain tension. Technetics Group also produces spiral-wound gaskets with mechanical characteristics controlled by the creation of a compression curve. These gaskets are referred to as “load certified.” Low seating load gaskets are also available upon request with VITAFLEX® BPA.

Product Features

- Design adaptable for all types of assemblies

- Wide choice of materials including Inox, Inconel®, Monel, PTFE and fibers

- Sealing up to 10-5 Pa.m3 /s helium

- Standard range meets the requirements of flange standards ASME B16.5 or NF EN 1759-1. but also NF EN 1092-1

Industries and Applications

- Chemical and petrochemical for use in catalytic synthesis, heat exchangers, vessel gaskets, piping, valves and storage

- Nuclear for use in cooling systems, valves, manholes, handholes and heat exchangers with or without partition walls

- For general industry use including high and low pressure steam systems, autoclaves, heat exchangers, heat transfer fluids, high pressure, hydraulic piping, valves, compressors and pumps

Properties and Technical Information

- Extreme Temperature and Pressure Performance

- Temperature: up to 1652°F (900°C)

- Pressure: up to 350 bar (5,076 PSI)

- Width Options and Measurements

Standard external winding diameters range from 12 mm to 1500 mm, although larger diameters requirements can be satisfied.

- Fire Safety

Both our VITAFLEX® and FLEXSEAL® spiral-wound gaskets have passed the fire test according to specification API6FB.

- Degreased Gaskets

Degreased gaskets are available for special applications, such as liquid oxygen service, transporting certain liquefied products, and others. Both VITAFLEX® spiral-wound gaskets with PTFE or CEFIGRAF® inserts may be degreased and shipped in individual packaging.