Sealing Expertise for Critical Flow Control Applications

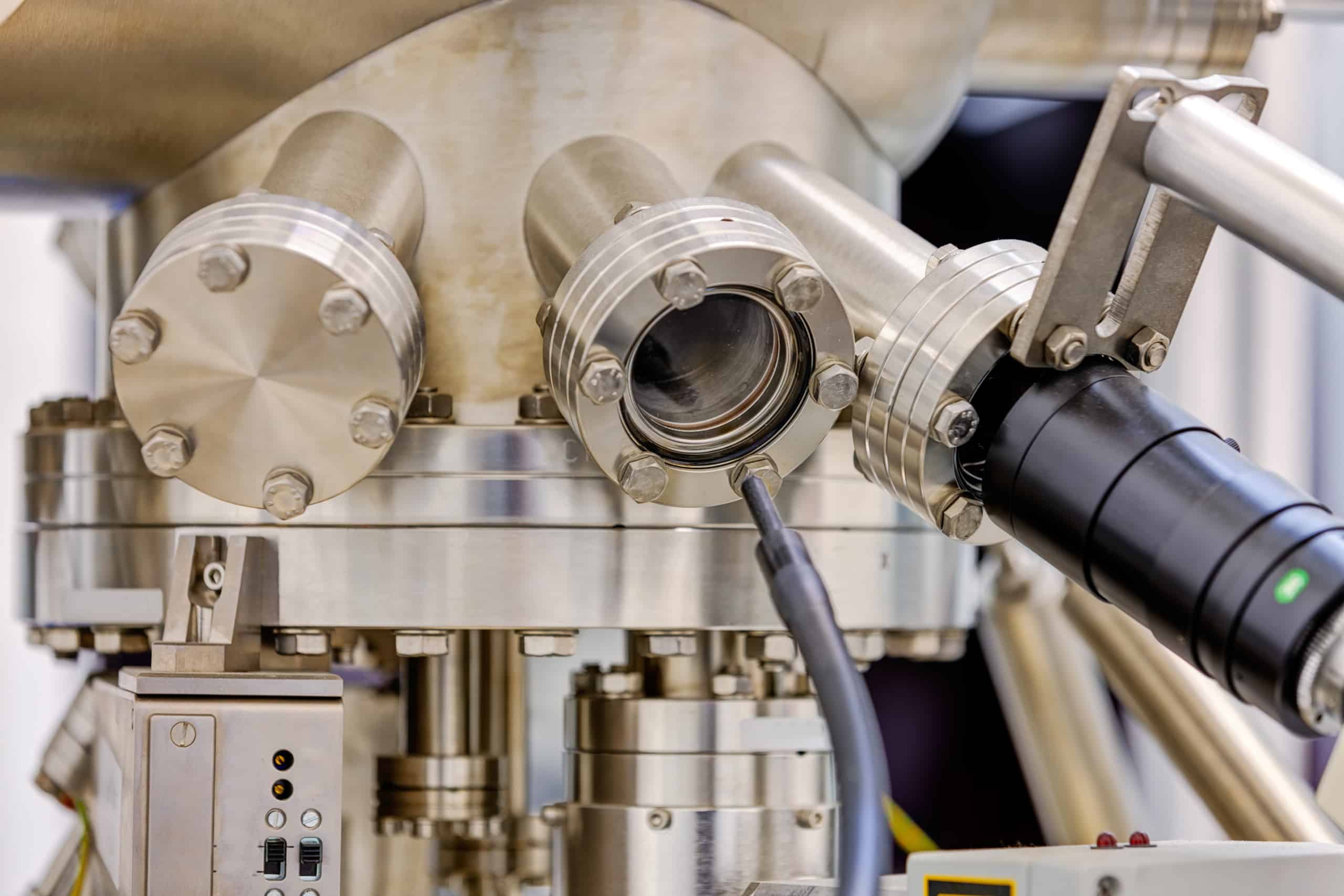

At Technetics Group, we deliver advanced sealing solutions engineered for precise flow control in the world’s most demanding environments. From valves and pumps to compressors, our seals ensure safe and reliable operation in systems handling critical fluids — even under extreme temperatures ranging from 1K (-423°F or -252°C) to 1,450°F (787°C). Built to resist corrosion, radiation and high pressure, our solutions are trusted where failure is not an option.

Engineered for Pressure. Trusted in Critical Industries.

We specialize in custom-engineered sealing technologies for flow control components, such as:

- Ball, Butterfly, Relief, Globe, Control, Check, Poppet and Gate Valves

- Cryogenic and high-temperature systems

- High-integrity pressure boundaries and ultra-high vacuum environments.

Our expertise supports mission-critical industries, including:

- Nuclear Power Generation – where safety, containment, and longevity are paramount

- Liquefied Natural Gas (LNG) – requiring cryogenic sealing performance and leak-tight reliability

- Hydrogen Infrastructure – where permeability, embrittlement and purity demand specialized sealing solutions

- Aerospace and Defense – for propulsion, fuel and thermal management systems

- Semiconductor Manufacturing – where ultra-clean, high-purity environments are essential

- Advanced Energy Systems – including fusion, SMRs and next-gen clean energy technologies

- Research and Big Sciences – including fusion and research labs

Built to Perform. Designed to Last.

Unlike standard gaskets or seals that degrade over time, our metal sealing technologies are engineered for long-term durability and minimal maintenance. We are at the forefront of sealing innovation — developing next-generation materials and designs that extend service life and enhance system reliability in the harshest conditions.

Case Studies

Sealing Solutions

You’ll find them deep inside nuclear reactors and within rockets soaring into space. Each of our products are engineered for safety, performance and durability.

Product Categories

PTFE & Polymer Solutions

Our Houston-based PTFE and Polymer Solutions division manufactures a full range of standard and custom polymer products and services.

Product Categories

Semiconductor Equipment Chamber Subsystems

We manufacture custom-engineered metal pedestals and heater assemblies, electrostatic chuck pedestals, and advanced subsystem assemblies.

Product Category

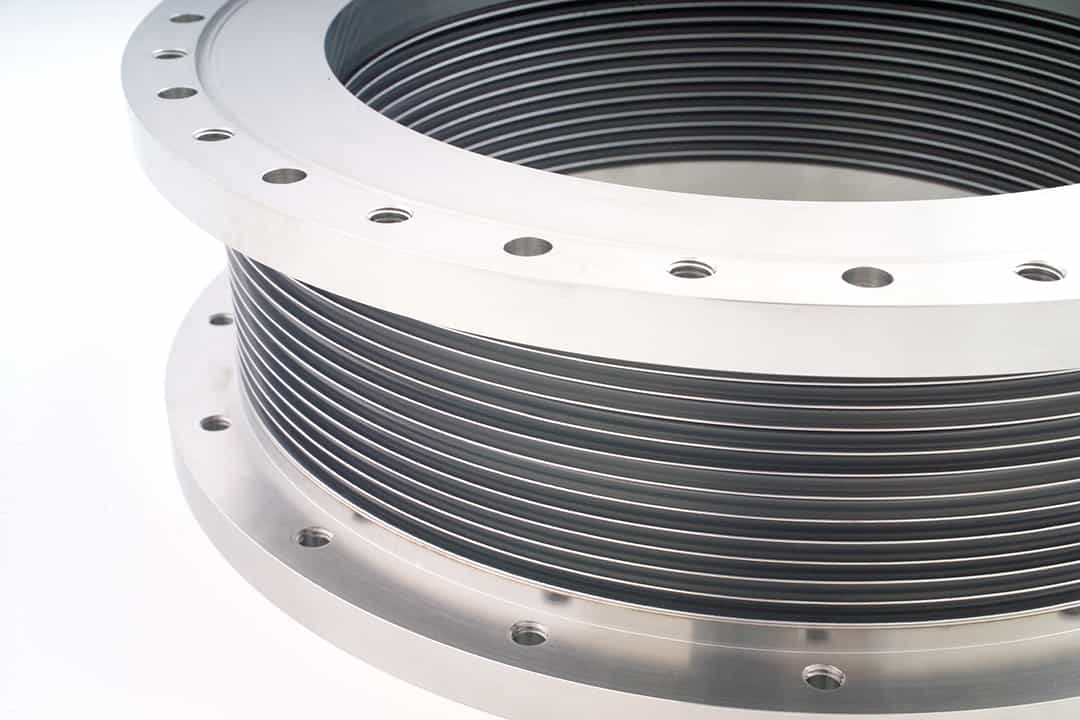

Bellows

With over 60 years of design experience and thousands of time-tested applications, Technetics Group has designed and produced edge-welded metal bellows longer than any other company.

Product Category

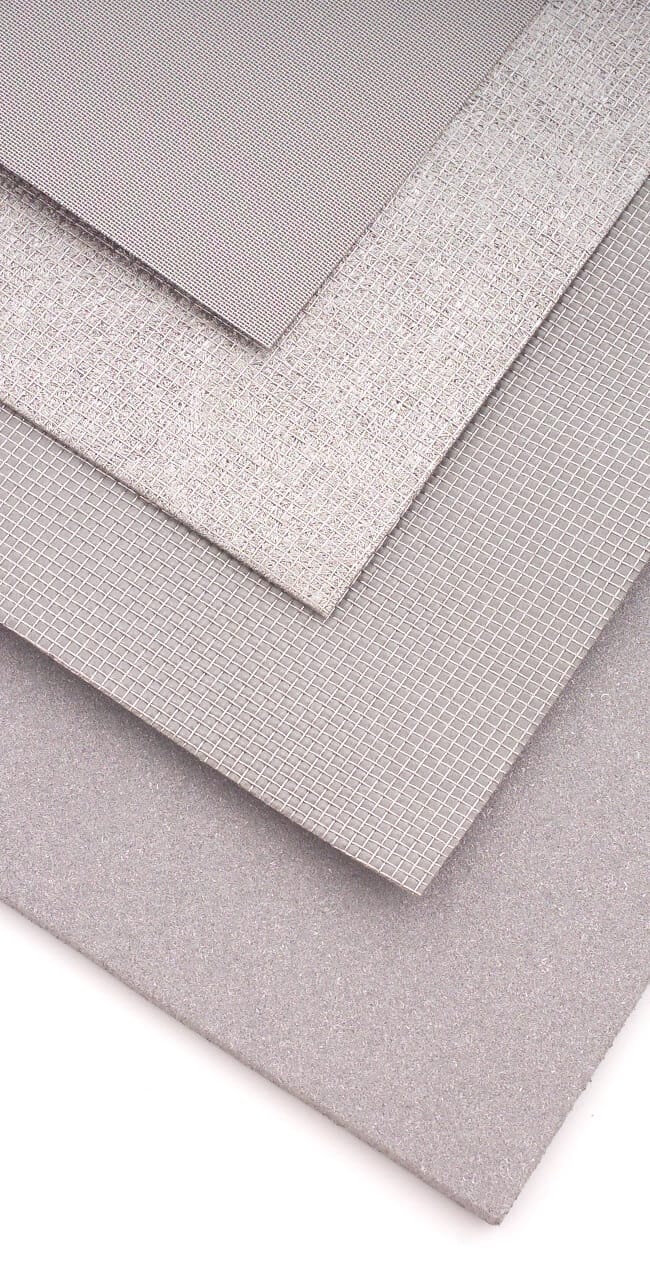

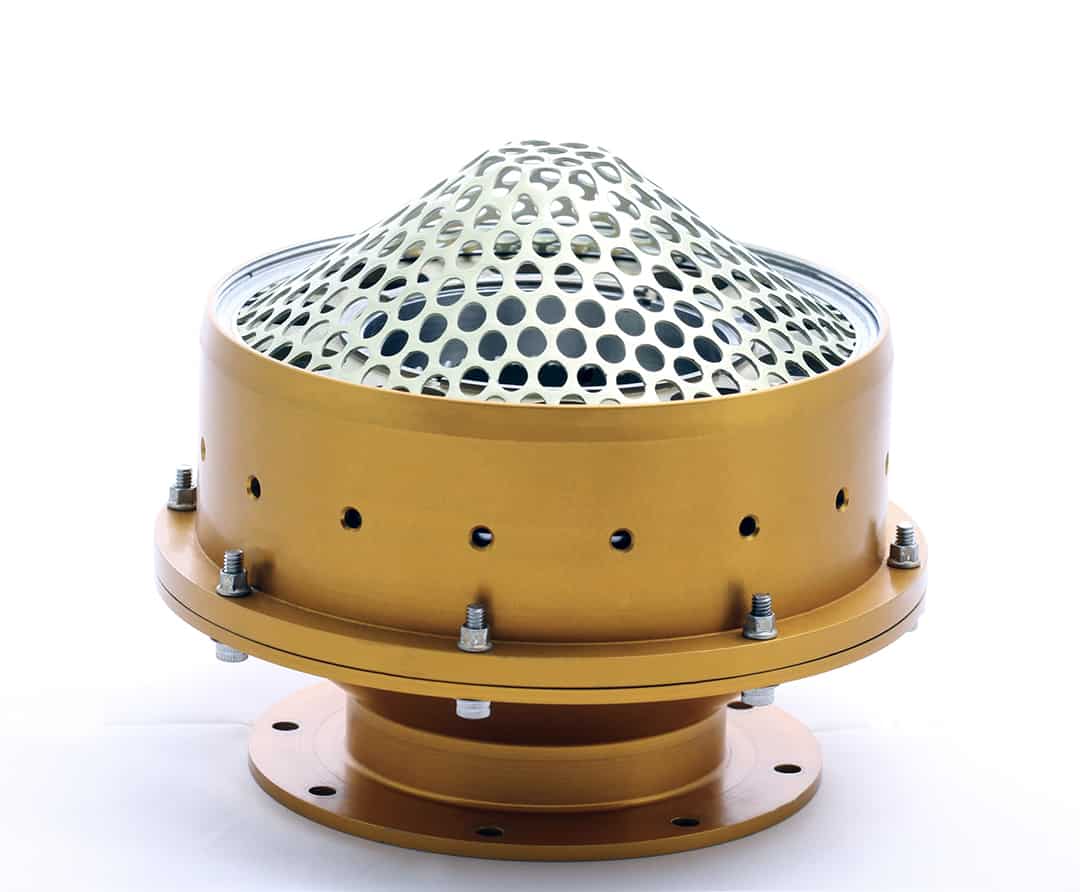

Acoustic Media

Our line of FELTMETAL™ Acoustic Media materials are specially designed to both absorb sound and provide enhanced structural properties at extreme temperature ranges.

Product Category

Burst Discs

High-precision burst discs (also commonly referred to as rupture disks, pressure safety disks, bursting discs or burst diaphragms) are non-reclosing pressure relief safety devices. They are used most often to protect pressure vessels, equipment or systems from over pressurization, or from potentially damaging vacuum conditions. Customized to fit your exact standards, our burst discs are ideal for hard vacuum, high pressure, cryogenic and high temperatures.

Product Category

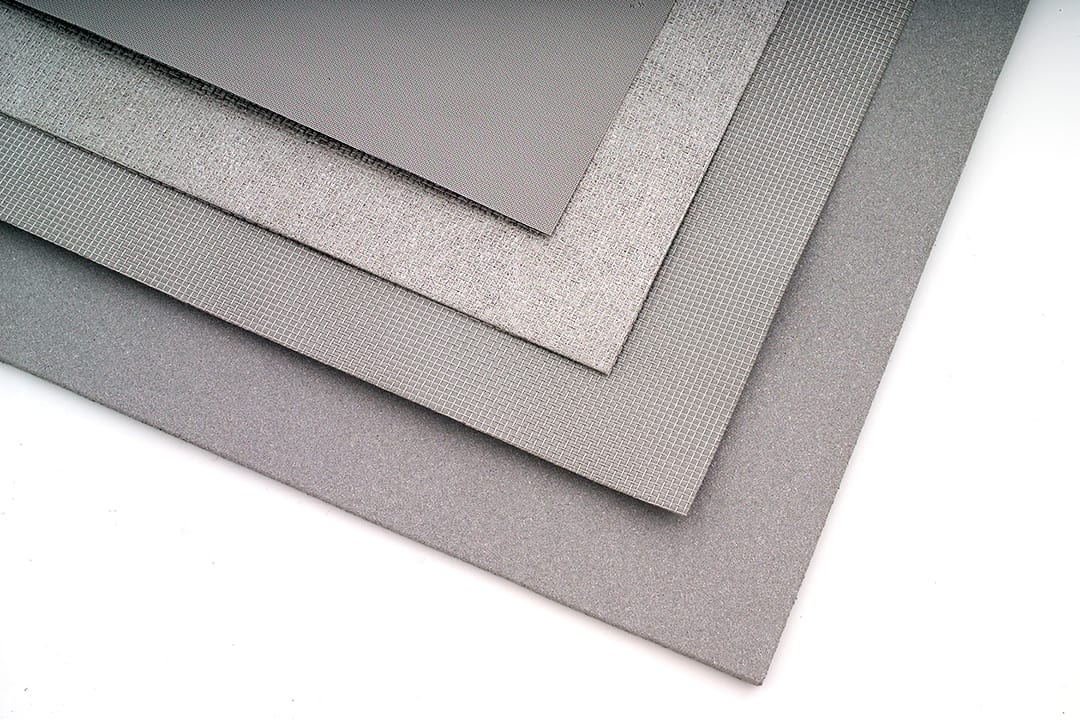

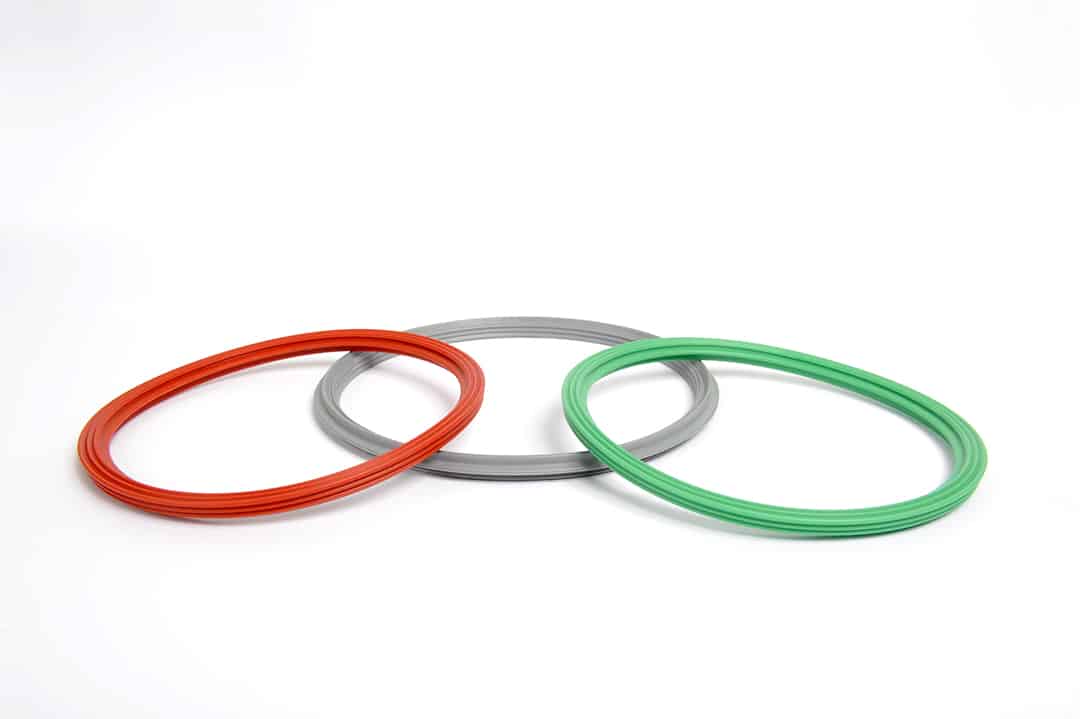

Flow Control Seals for Critical Applications

Maximize safety, performance and long-term value with ORIGRAF® die-formed expanded graphite seals from Technetics.

Designed to outperform in extreme thermal and pressure cycling environments, ORIGRAF® seals deliver:

- Superior sealing integrity under fluctuating conditions

- Enhanced operational safety

- Reduced maintenance and downtime

- Optimized total cost of ownership

Whether you’re operating in high-temperature, high-pressure or chemically aggressive environments, ORIGRAF® seals provide the durability and consistency for your critical systems demand.

Why Choose ORIGRAF® Expanded Graphite Seals from Technetics Group?

ORIGRAF® die-formed expanded graphite seals are engineered to deliver exceptional sealing performance in the most demanding environments — where conventional solutions often fall short.

Unlike standard graphite gaskets or competitor expanded graphite seals, ORIGRAF® seals offer superior adaptability and resilience. Thanks to our proprietary manufacturing process, the graphite structure maintains flexibility, allowing the seal to conform to surface irregularities — even under offloading or transient conditions. This ensures consistent, leak-tight performance where others may fail.

What Makes ORIGRAF® Stand Out?

- Controlled Compression

Unlike flexible graphite-cut gaskets or spiral-wound gaskets, ORIGRAF® seals are designed with mechanical stops — such as precision-engineered grooves or inner/outer rings — that limit compression. This prevents overloading and protects the seal during thermal and pressure fluctuations. - Superior Stress Management – Built for Critical Applications

The design minimizes excessive sealing stress, preserving seal integrity and extending service life when assemblies are subject to high-pressure, high-temperature environments. ORIGRAF® seals are trusted in industries where safety, reliability and performance are non-negotiable — from energy and chemical processing to aerospace and defense.

Choose ORIGRAF® for a smarter, safer and more cost-effective sealing solution — engineered to reduce maintenance, improve operational safety and lower your total cost of ownership. Outperforming other manufacturers in real-world conditions.

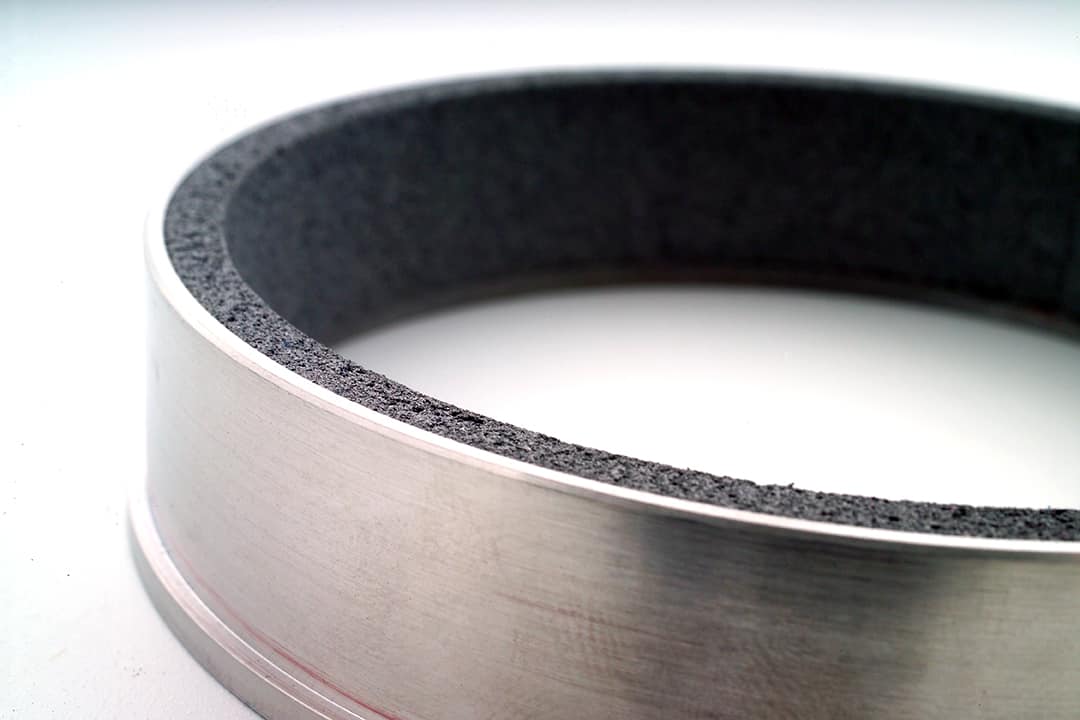

Key Features of ORIGRAF® Expanded Graphite Seals

Engineered for performance in the most demanding environments, ORIGRAF® expanded graphite seals offer a unique combination of resilience, adaptability and ease of use:

- Exceptional Elastic Recovery

Achieves up to 40% compression recovery, delivering a reliable spring-back effect for long-term sealing performance (characterized in our MAESTRAL Laboratory). - Low Creep and Relaxation

Maintains dimensional stability under critical pressures and temperatures, reducing the need for retightening. - Radiation and Chemical Resistance

Ideal for nuclear and chemical processing applications, with excellent resistance to harsh media and radiation exposure (specific nuclear graphite grades on request — for instance, PMUC). - Thermal and Pressure Adaptability

Performs reliably under extreme temperature and pressure fluctuations, ensuring consistent sealing in transient conditions. - Metal-to-Metal Contact Design

Enhances structural strength and ensures consistent seating load control. - Insensitive to Asymmetric Bolt Tightening

Maintains sealing performance even when assembly torque is uneven — reducing installation errors and improving reliability. - Non-Adhesive to the Flanges Contact Surfaces

Usually does not bond to flanges, making removal and replacement quick and damage-free during maintenance.

Industries & Applications

ORIGRAF® expanded graphite seals are trusted across a wide range of high-demand industries where safety, reliability and performance are critical:

Industries Served:

- Nuclear Power & Research

- Chemical Processing

- Petrochemical & Refining

- Oil & Gas Exploration & Production

Common Applications:

- Steam Generators & Pressurizers

- Manholes & Other Critical Maintenance-Related Openings

- Heat Exchangers

- Piping Flange Connections

- Valves & Pumps

- Critical Flange Assemblies

Technical Specifications & Certifications

Engineered for extreme environments, ORIGRAF® seals deliver consistent performance under the most challenging operating conditions:

- Pressure Resistance: Up to 400 bar (5,802 PSI)

- Temperature Range: From -321°F to 4,532°F (-196°C to 2,500°C)

- Standard Sizes:

- DN: 15 to 600 mm (NPS: 1/2” to 24”)

Up to 1,500 mm (59”) on special request - Pressure Classes: CLASS 150 to 2500 / PN 20 to 420

- DN: 15 to 600 mm (NPS: 1/2” to 24”)

- Certifications:

- PMUC Certified by EDF (No. PMUC 17-0174)

- BAM Certified for use in oxygen-rich and high-risk environments

ORIGRAF® ON 002 Gaskets

Designed for compatibility with a wide range of flange types and standards:

- Suitable for flat-faced (FF) and raised-face (RF) flanges

- Supports single insertion (SE) configurations

- Compliant with NF-EN 1092-1 and NF-EN 1759-1 (ASME/ANSI B16.5) standards

Looking for a sealing solution that meets nuclear-grade standards and performs under extreme conditions?

ORIGRAF® seals are engineered to deliver maximum safety, minimal maintenance and long-term reliability — making them the preferred choice for engineers in the world’s most demanding industries.

Engineered to Perform Under Pressure — Anywhere

From the depths of the ocean to the heart of a nuclear reactor, Technetics delivers precision-engineered sealing solutions that keep valves operating safely, efficiently and reliably. Whether you’re designing for industrial processing, power generation or extreme environments, our components are built to meet the challenge.

Trusted by Leading Valve Manufacturers Worldwide

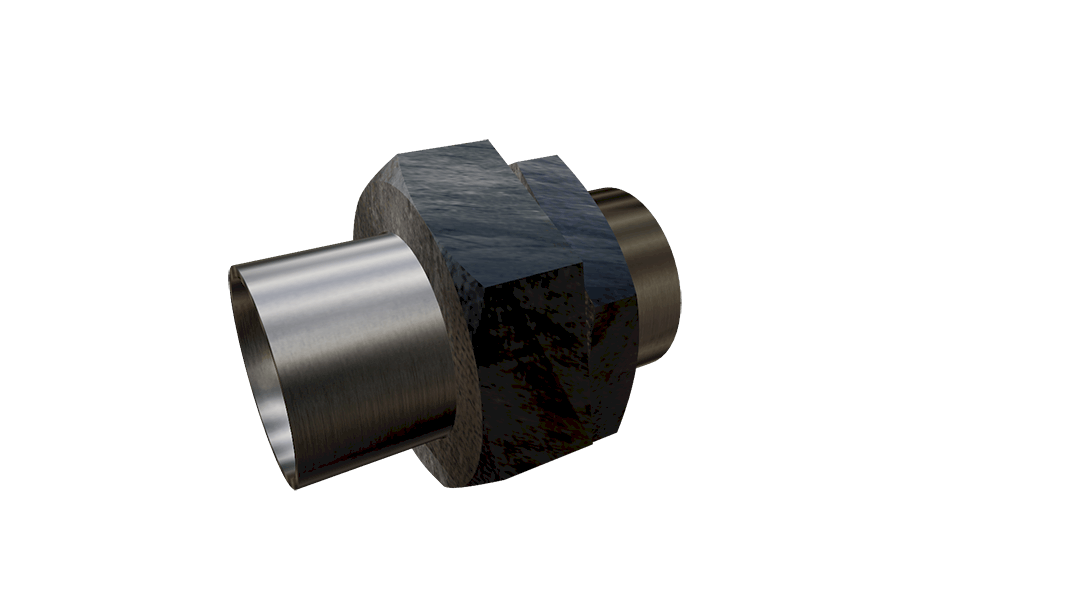

Technetics is a preferred partner for OEMs and system integrators across the globe. We design and manufacture critical components for specific valves:

- ¼-turn valves

- Globe, gate and check valves

- Control valves

- Safety-relief valves

Our solutions are tailored to meet the most demanding specifications, ensuring long-term performance and leak-tight integrity in high-pressure, cryogenic to high-temperature and corrosive environments.

Advanced Materials and Technologies

We offer a wide range of high-performance materials and sealing technologies, including:

- Metal seals (including spring-energized HELICOFLEX® seals) – For extreme pressure and temperature resistance

- High-performance ORIGRAF® graphite seals – For chemical or radiation compatibility and exceptional elastic recovery

Each component is rigorously tested and validated to meet or exceed industry standards for safety, durability and performance.

Applications Across Critical Industries

Our valve sealing solutions are trusted in:

- Nuclear Power Plants

- Oil & Gas Exploration, LNG Value Chain

- Chemical Processing

- Aerospace and Defense

- Marine and Subsea Systems

- Research and Big Sciences

Wherever reliability is non-negotiable, Technetics delivers.

Why Choose Technetics?

- Decades of proven expertise in critical sealing applications

- Custom-engineered solutions for your exact valve design

- Global support and responsive engineering collaboration

- Commitment to innovation and continuous improvement

Ready to enhance your valve performance?

Let’s talk about how Technetics can help you reduce downtime, improve safety and extend the life of your systems.