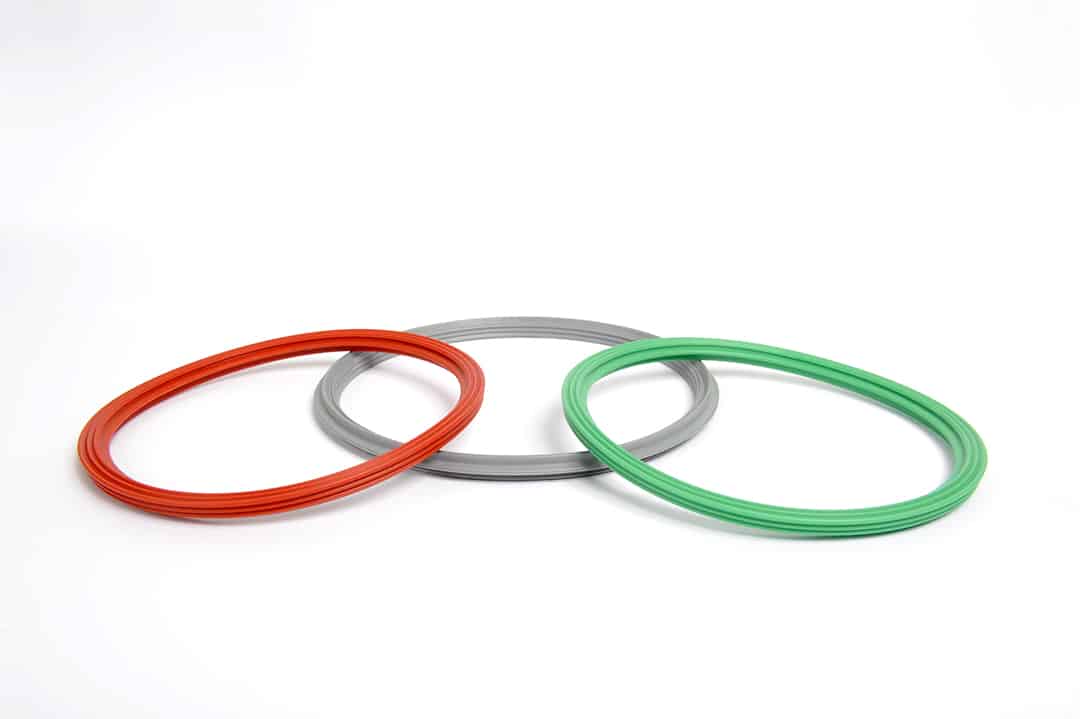

Molded Seals

Made from a wide range of technological elastomers, Technetics Group molded solutions meet the critical temperature, chemical and mechanical requirements in nuclear, pharmaceutical and aerospace industries. Technetics produces custom, precision-molded seals and can incorporate internal and external reinforcement from an extensive selection of materials. Technetics uses compression, transfer and injection molding techniques in the manufacturing processes. Technetics can also supply assemblies consisting of molded seals and other customer required elements as well as cut gaskets from molded sheets. Technetics can provide seals with EMI protection.

Features & Benefits

- Large material selection: BIO-GUARDIAN®, Silicone, EPDM, FKM, HNBR, and other materials (see specification table)

- With fabrics or inserts

- RFID chip can be included for traceability & reliability

- All shapes available meeting your specifications

- High chemical inertia and compatibility with food and pharmaceutical applications

- Elastomer with antibacterial properties (BIO-GUARDIAN®)

- Flexible design and custom applications

- Adaptation to environment and service conditions

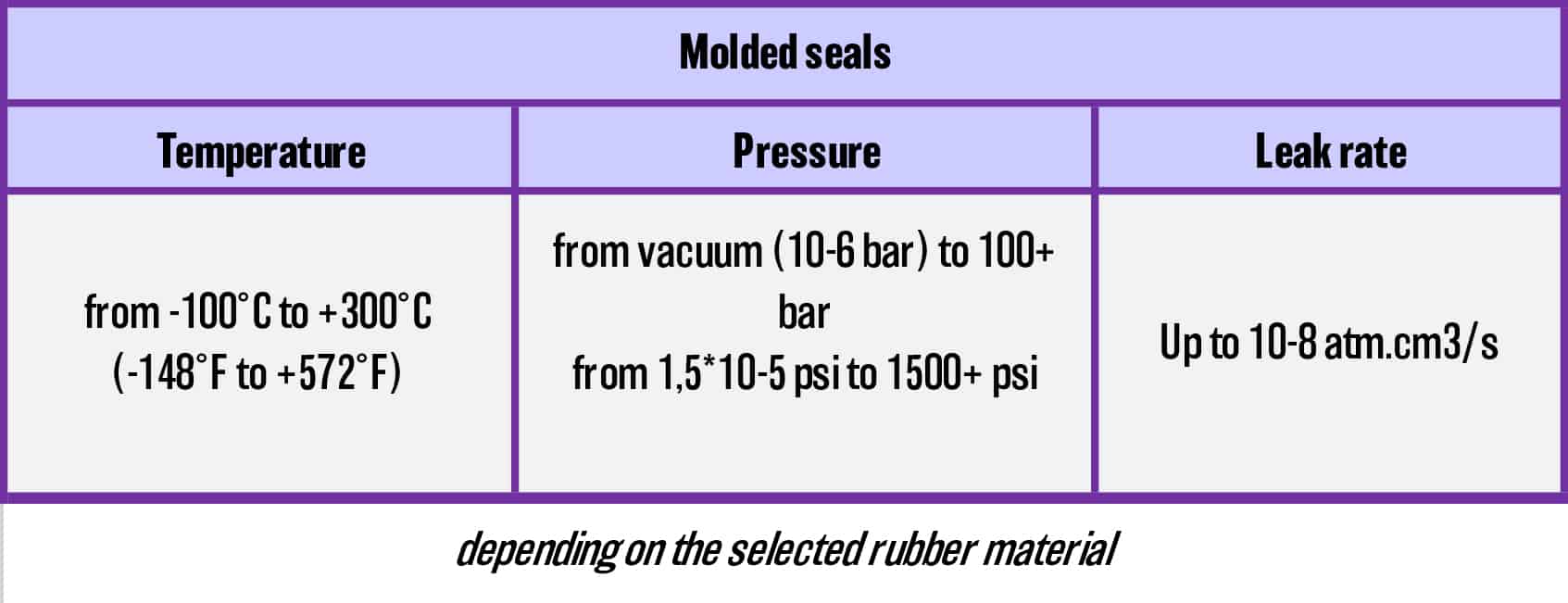

- Large range of operating conditions

- For use with various fluids

Product Applications

Pharmaceutical industry:

- Sealing on isolators’ doors & gloves

- Membranes & septums

Nuclear:

- Large shutters

Industry:

- O-Rings & various gaskets

- Butterfly valves seats

- Dampers, stoppers & plugs

- Electric insulation