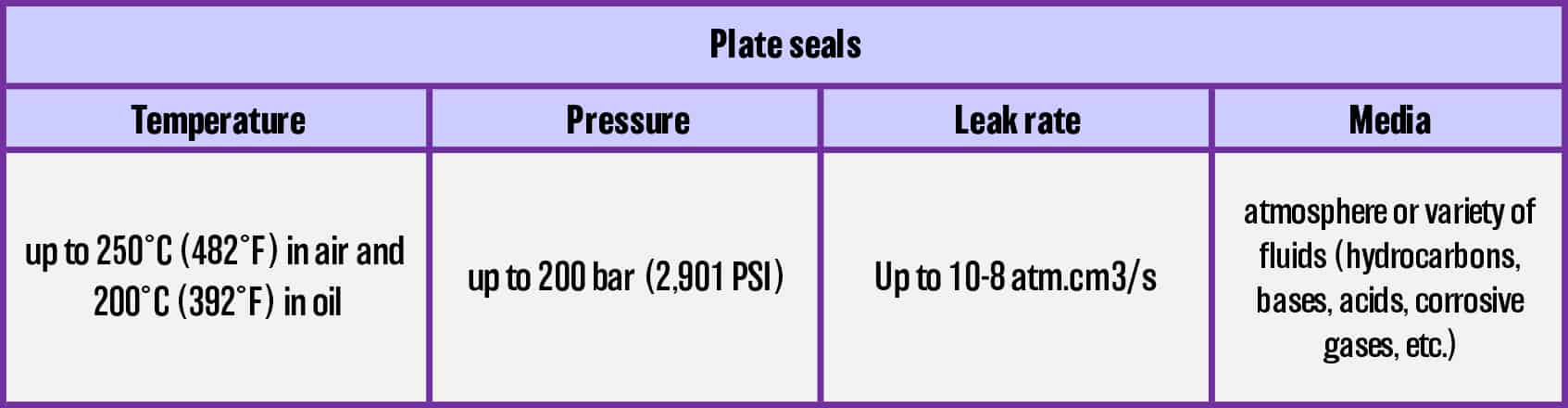

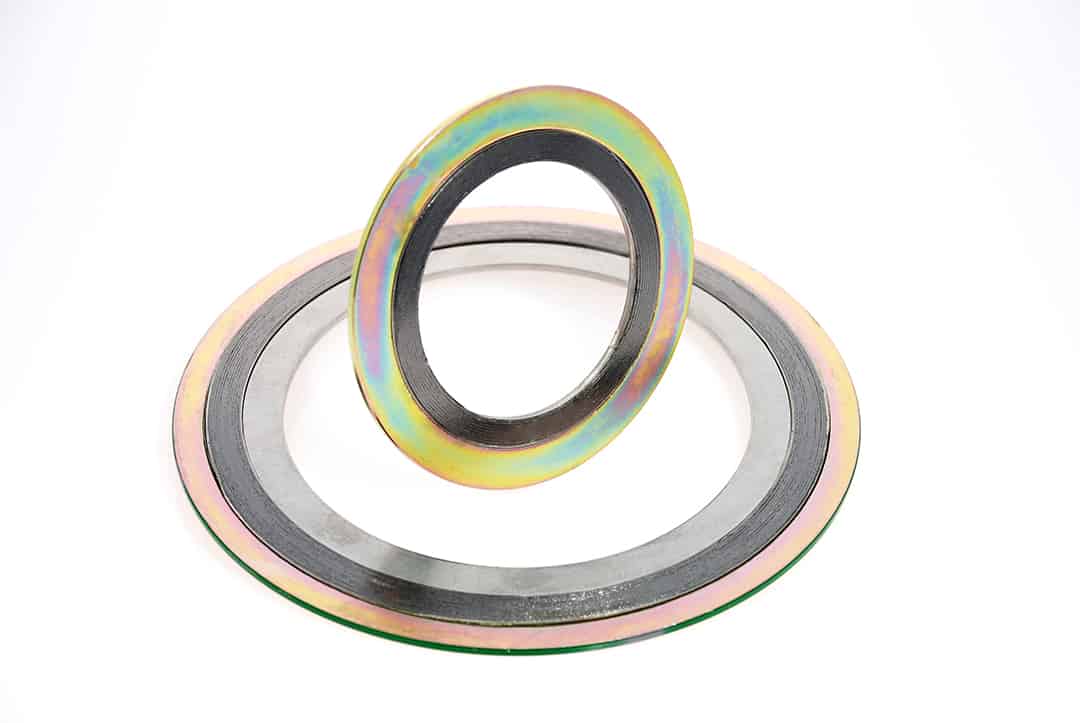

Plate Seals

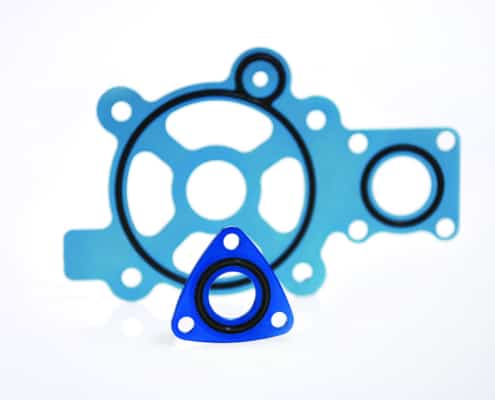

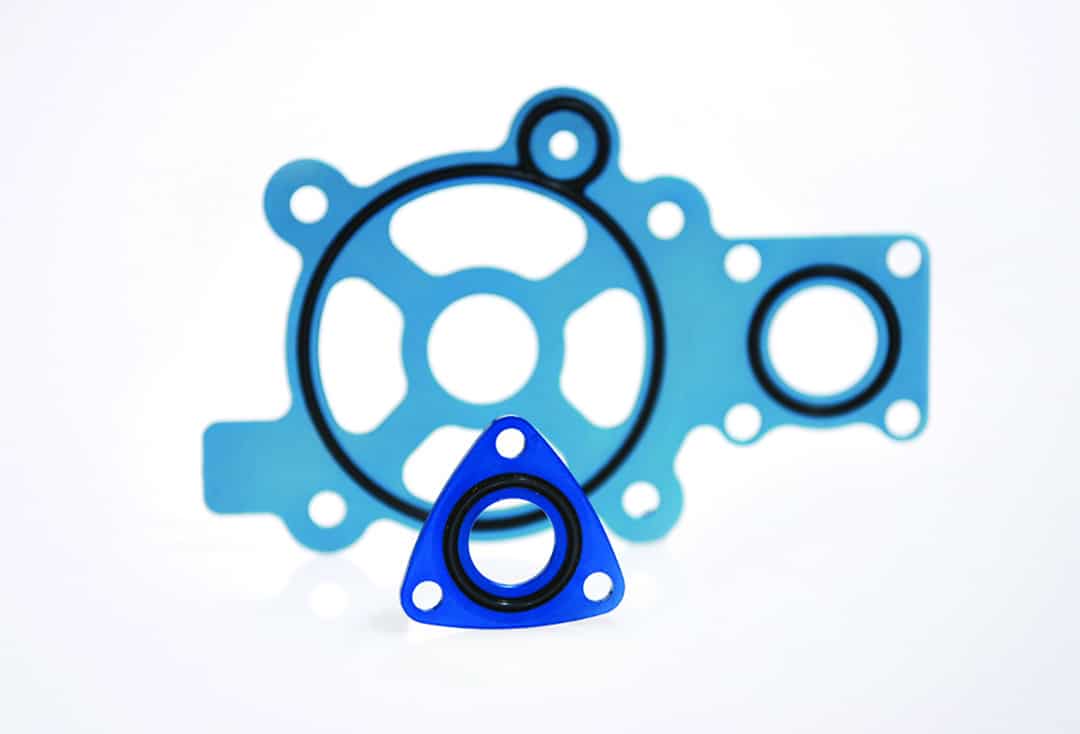

Overmolded plate seals

Elastomer seals (FKM, silicone, fluorinated silicone) can be overmolded within grooves on anodized aluminum or nickel-plated supports. This enables perfect positioning between elements to be sealed, independently of the orientation and accessibility of the seal.

Features & Benefits

- Simple, visually & verifiable installation (correct location of the rubber part in front of the sealing surface)

- High-pressure performance (more than 200 bars as well as vacuum)

- Easy maintenance even in a vertical position with very low space between flanges

- Multi-port sealing with one component

- Ability to seal complex flange geometry.

- Solid metal-to-metal contact insures stable joint with no re-torque required

- Redundant seals can be incorporated into one component

- No machined grooves required in mating flanges

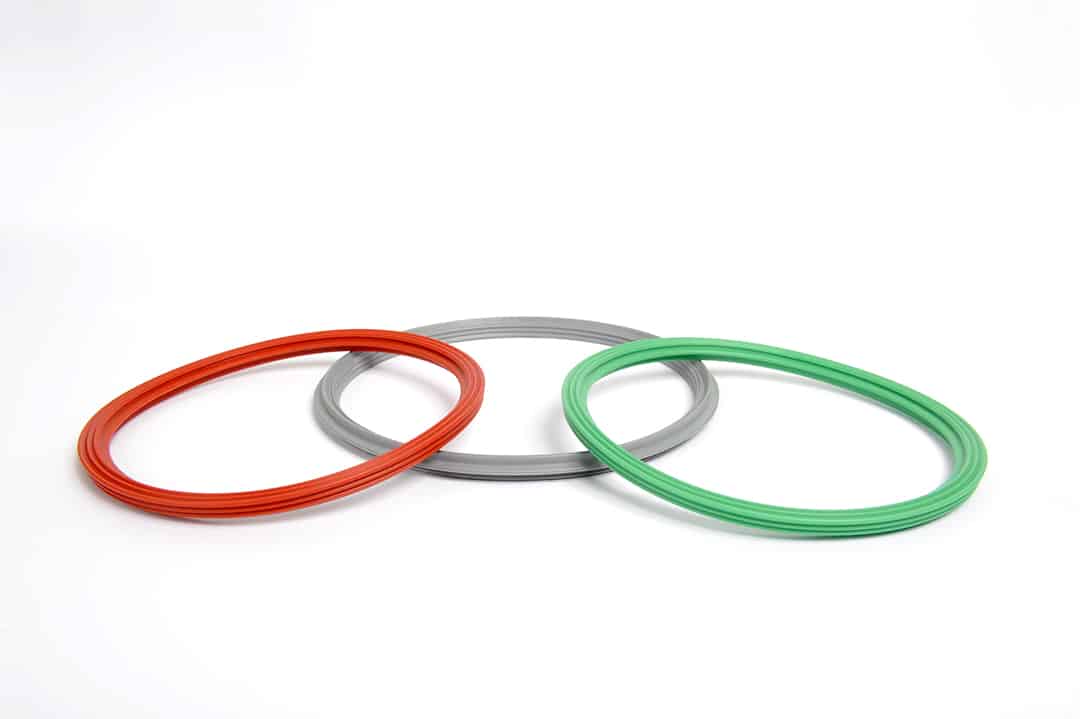

- Different rubber and materials (and coatings) retainers: FKM, Silicone and Fluorosilicone seal materials

- Specific design features (metal-to-metal design, special seal profile) contribute to safe static sealing of aircraft fuel systems

- Can also be used in dynamic applications (relief valve, poppet valve)

Product Applications

Aircraft engines:

- Sealing on compressors, pumps & gearbox assemblies

- Sealing on flanges and connections of air, oil & fuel management systems

- High sealing pressure on Kerosene post combustion’s hydraulic device

Hydrogen production:

- Sealing on separation stacks

Nuclear:

- Sealing on primary pumps filters