Critical Solutions for Life Sciences

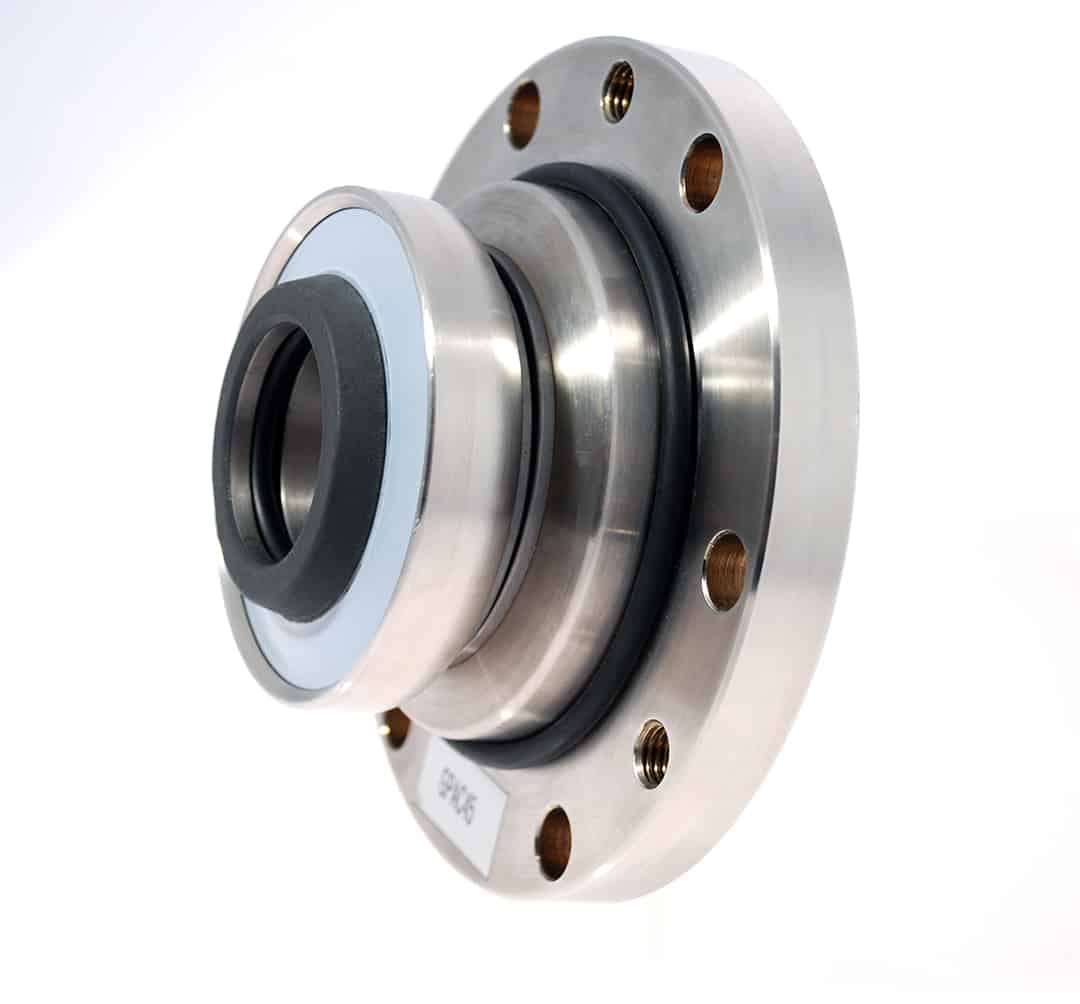

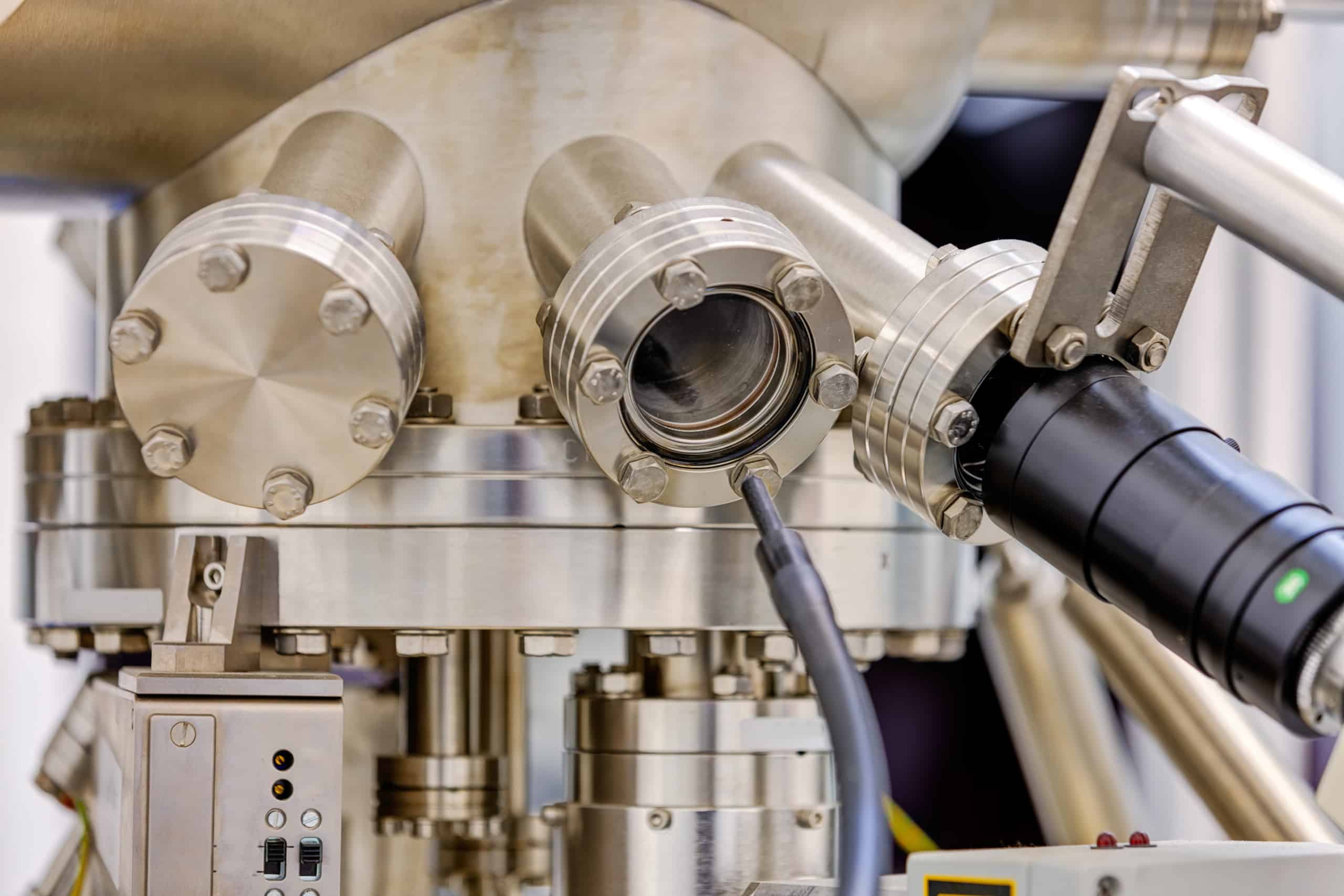

When clean is critical, Technetics Group produces sealing solutions that matter. In the clean-room environment, seal integrity is needed to prevent air leaks, ingredient accumulation, gasket fragmentation and the development of microorganisms. We provide the components that give you confidence in your seals, even in the most demanding conditions.

Collaboration Matters

With our leading in-house testing and design capabilities, we are able to tackle the most complex sealing challenges. Our Technetics Group sales and engineering teams work closely with you from design and development, through prototyping and production, whether we’re working to improve current solutions or develop new ones.

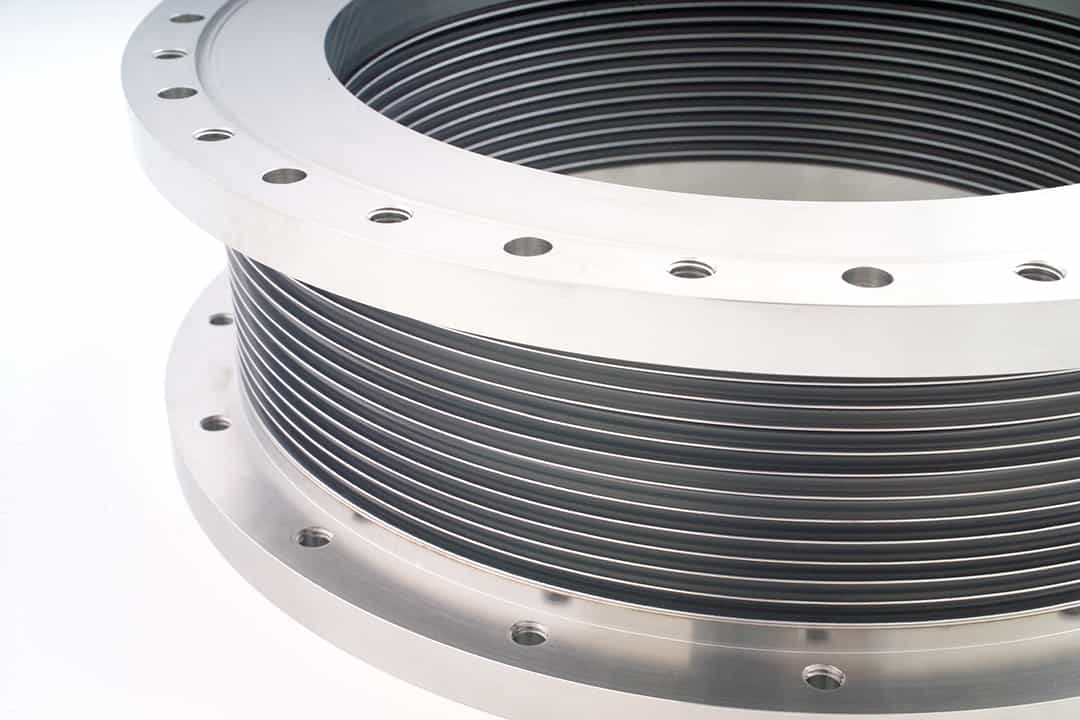

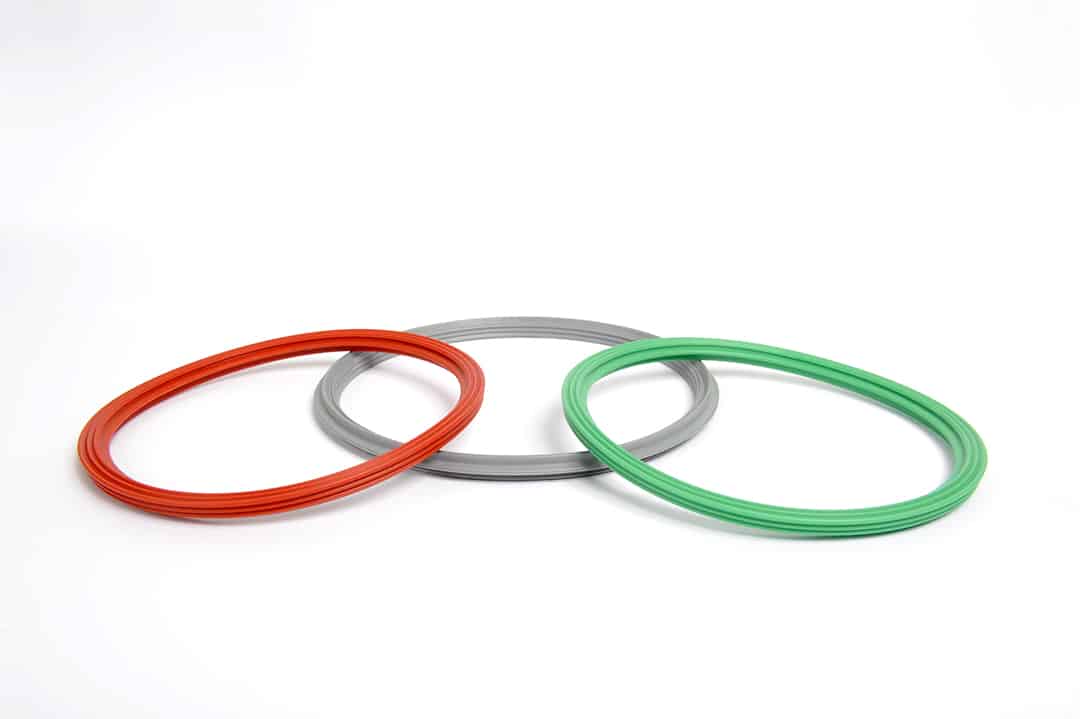

CEFIL’AIR® Inflatable Seals provide smooth operation for the doors and openings in pharmaceutical and medical equipment. These elastomer seals offer maximum safety in your manufacturing processes in compliance with current regulations. This unique sealing solution allows for optimizing the design and operation of your equipment and its use in compliance with Good Manufacturing Practices (GMP). Further, our BIO-GUARDIAN® compound prevents bacterial and microbial growth in the manufacturing process. Our sealing solutions are custom-engineered with numerical simulation and FEA Analysis to ensure our seals meet your exact requirements.

We at Technetics Group stand at the forefront of the industry, underpinned by a legacy of over 150 years in advanced sealing technology. Our experts specialize in precision-engineered solutions designed to address the most stringent requirements with precision. During the COVID-19 pandemic, our ability to scale production swiftly and efficiently showcased our adaptability and unwavering commitment to quality.

Our journey through this unprecedented time illustrates our readiness to meet challenges head-on, contributing decisively to global health efforts—without sacrificing our standards of excellence.