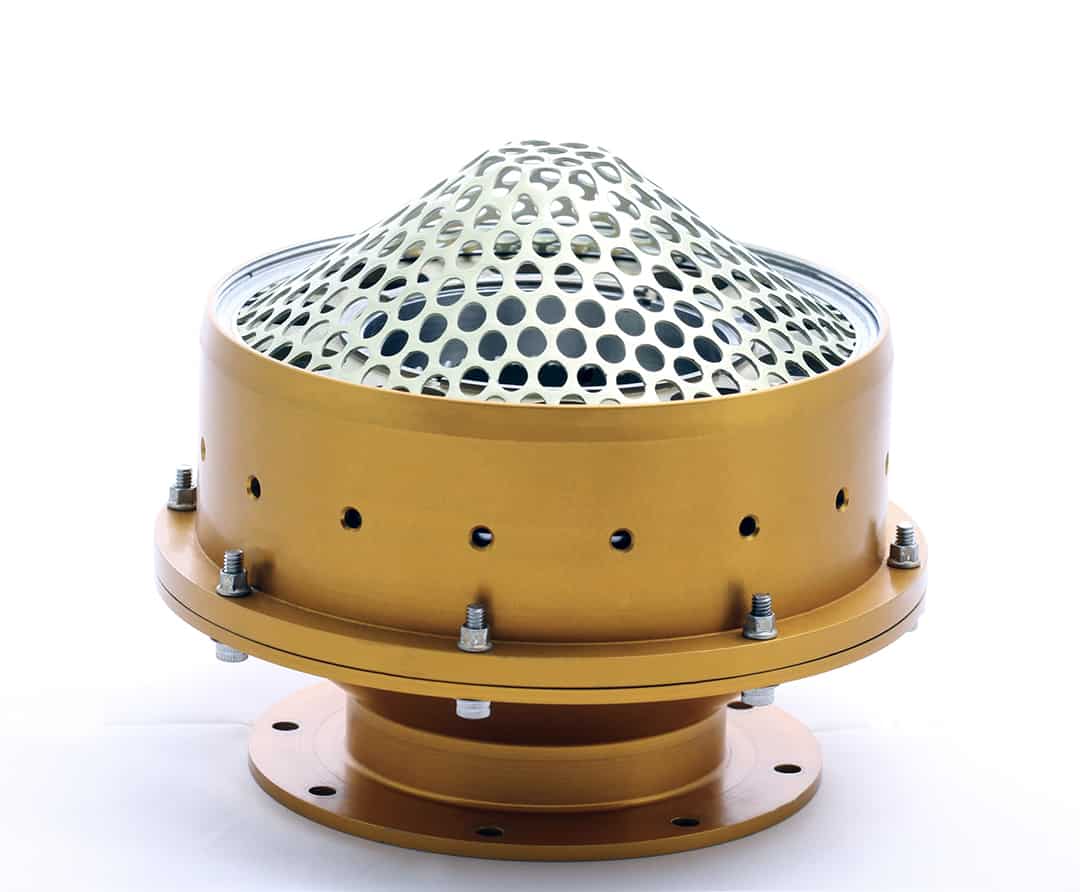

When extreme conditions demand the best components, second best won’t do. Technetics Group SAFE-SHEAR™ Burst Discs are second-to-none in delivering reliable, consistent performance in the most extreme conditions such as hard vacuum, high pressure, cryogenic and high temperatures.

Our SAFE-SHEAR™ Burst Discs assemblies support a wide variety of programs ranging from Human Spaceflight, orbital refueling, autonomous spacecraft and a multitude of satellite platforms. Our pedigree includes the International Space Station, Orion, RRM3 Orbital Refueling Mission, Space Shuttle, Aries, Hubble Telescope, Spitzer Telescope and deep space platforms such as the Mars Global Surveyor and the Cassini spacecraft that travelled to the outer solar system. We are also at work protecting aircraft fuel systems such as the Bell Boeing V-22 Osprey and the Embraer KC-390 Millennium.

About Technetics Group Overpressure Protection Solutions

Technetics Group SAFE-SHEAR™ Burst Discs are rupture discs designed to meet your exact standards and protect your system from over-pressurization or over-vacuumization. With fully-welded construction, they offer leak tightness of <1.00×10-9 sccs He, which is far superior to a standard pressure relief valve. Our burst discs can be designed with an integrated pressure relief valve which can re-seat after an overpressure event.

Product Features

-

Technetics SAFE SHEAR® Burst Discs are rupture discs selected by NASA for the Orbital Cryogenic Propellant Refueling RRM3 Mission onboard the International Space Station.

High level of accuracy and dependability (± 1% full scale) regardless of pressure and temperature cycles, dynamic environments and harsh media

- Burst setting 100% verifiable and adjustable by nondestructive testing

- Achieves leak tightness of <1.00×10-9 sccs He, considerably better than pressure relief valves alone

- Allows continuous pressure cycling up to 95% of set burst pressure

- Impervious to high shock and vibration levels: does not cause premature rupture or reduced life

Industries and Applications

- Human spaceflight – Meet NASA Fracture Critical Requirements – e.g. ISS, Orion, etc.

- Autonomous space vehicles – Extensive pedigree that began in the time of the Mercury Missions

- Cryogenic fluid management – Orbital refueling (e.g. NASA RRM3 Mission)

- Deep space applications – 20+ year Cassini Mission to Saturn – Prevented Boil-off leakage for over two decades

- Sensitive rail cargo – Vapor phase piping system where LNG or ethylene is being transported

- Transport aircraft fuel systems

Properties and Technical Information

- Tested and Qualified

- SAFE-SHEAR burst discs have been tested through millions of cycles without failure or setting creep, up to 95% of rupture.

- Tested and qualified to various RTCA DO-160, MIL requirements.

- Technical Characteristics

- Pressures: 1 to 10,000 psi (.07 to 690 bar)

- Rupture tolerance: up to 1% Full-Scale Pressure

- Reverse pressure protection: full reverse, cycling

- Temperature: -457°F to 1,000°F (-271°C to > 540°C)

- Leakage: <1.0×10-9 sccs He

- Size: <.25” to over 3.0” (76mm) free flow area

- Mass: variable, based on usage

- Mounting: flange, weld to tube, custom

- Shock: pyrotechnic, operational & crash safety

- Vibration: launch, abort, ground, runway, high to low frequency

- Media: compatible with jet & rocket fuels, oxidizers, other harsh fluids

- Life: MTBF > 1,000,000 hours of operation (NPRD-95)

- Available Materials

- Aluminum, Stainless, Titanium, Inconel® and Superalloys, and PTFE.