Critical Solutions for Industrial Turbines

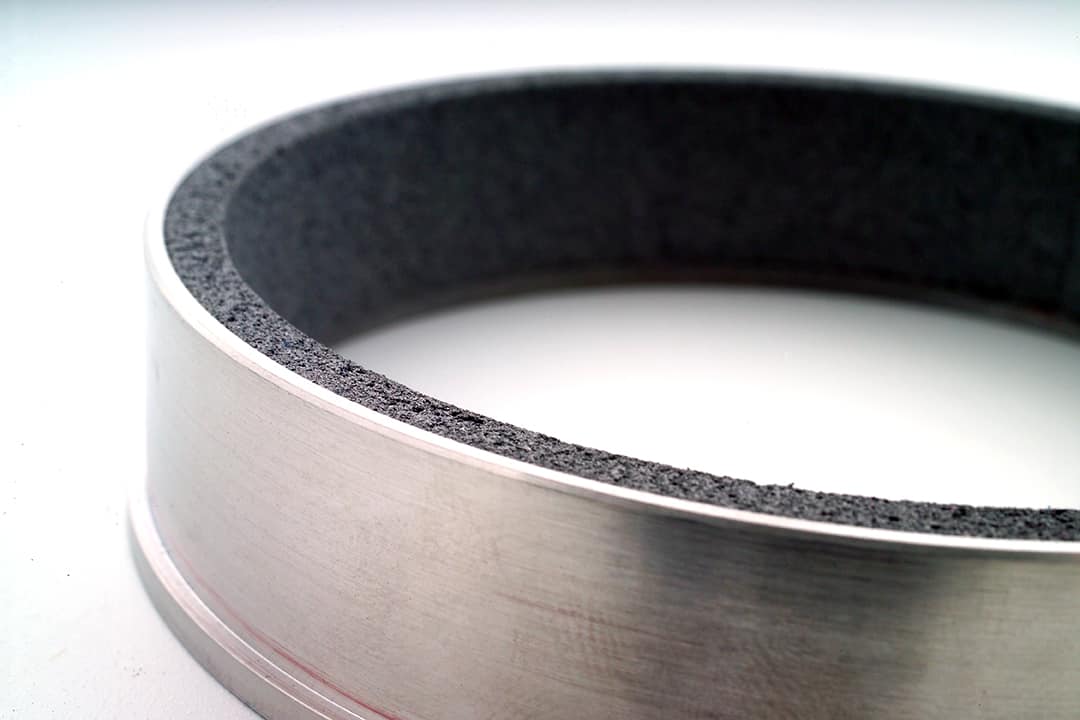

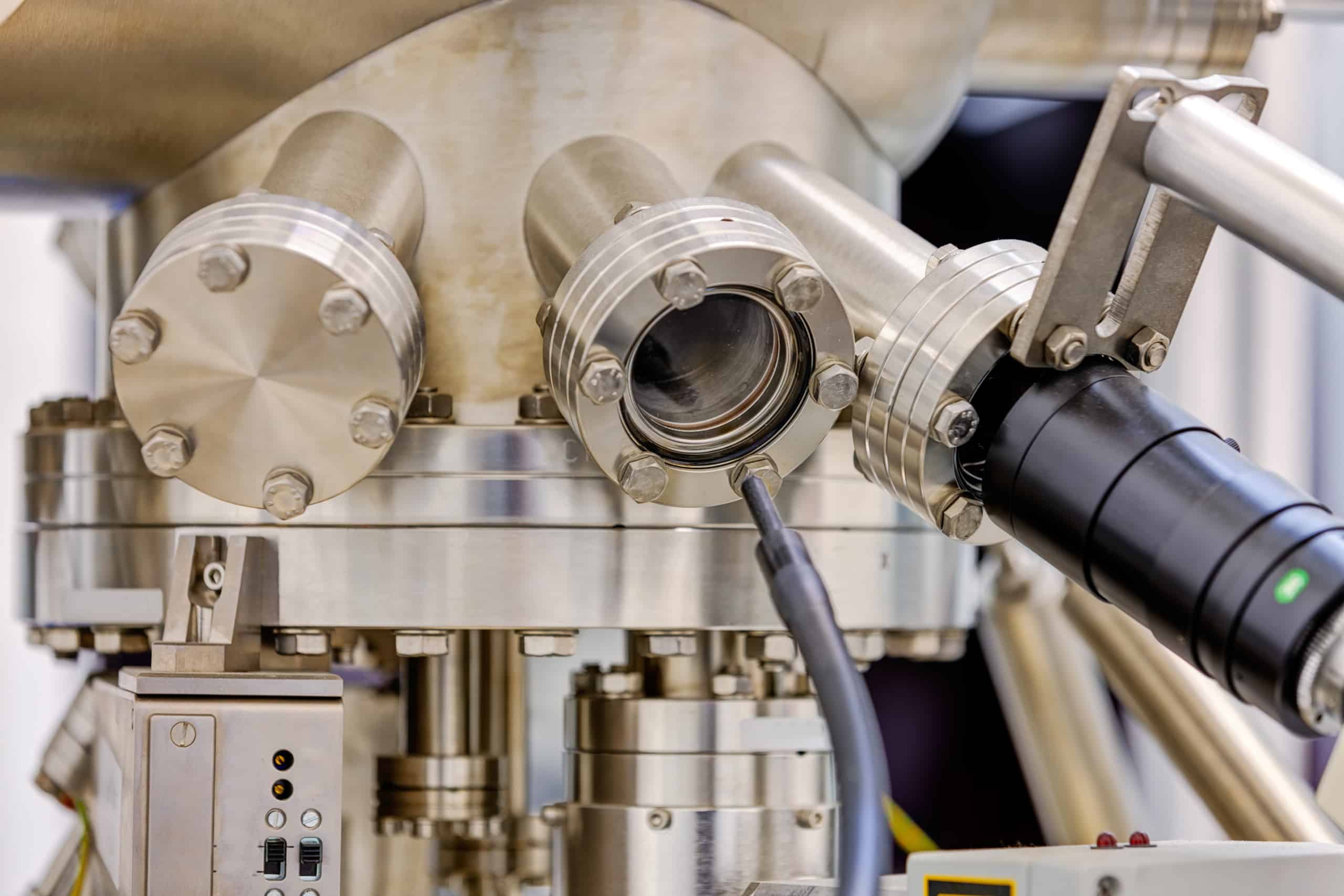

We help you deliver power with confidence. It all begins with our extensive research and development services which, for many of our products, includes comprehensive in-house testing and inspection. We continue to outperform with impressive custom machining, fabrication, and small-batch prototyping capabilities. Whether we are manufacturing metallic brush seals to reduce leakage for Industrial Gas Turbines (IGT’s), or exclusive FELTMETAL™ abradable seals to improve flow path efficiency, our industrial turbine sealing solutions are unequaled in performance and safety.

Working Together

For us, product development is a collaborative effort with our customers. When the complexities of your unique application’s needs are identified we deliver tailored solutions that meet your time, quality and budget specifications.

Changing Times

Industrial turbines are constantly being re-developed and re-designed, and you need confidence that your components will keep pace. At Technetics Group, our sealing solutions outdistance your high expectations. Our solutions are not only up-to-date but future-focused to meet tomorrow’s requirements for a wide range of mature industrial turbines, mobile and stationary turbines, and heat recovery steam generators. By machining to very tight tolerances, we can ensure consistent performance and airflow across the turbine.