When noise is an issue, Technetics Group’s acoustic media quietly does the job. Our FELTMETAL™ Acoustic Media provides enhanced noise control for applications such as inlet and exhaust for both APU and propulsion engines. FELTMETAL™ is also used in environment control systems to reduce noise and control moisture inside the cabin.

About Technetics Group Acoustic Media

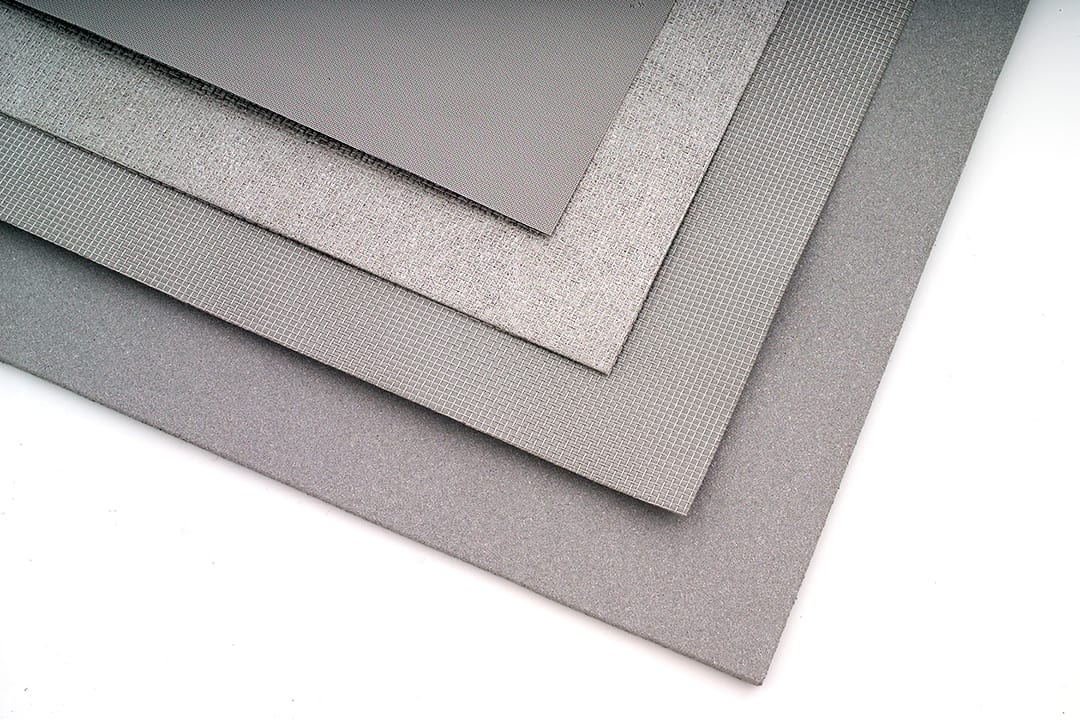

Technetics Group FELTMETAL™ Acoustic Media can be found in the crew cabins onboard the International Space Station (ISS), and before that, on Skylab. We help keep the aircraft cabin quiet within the environmental control systems (ECS), such as our application on the Boeing 787 Dreamliner. The extreme temperature performance of FELTMETAL™ allows it to operate in both inlet and outlet applications onboard Airbus and Boeing commercial aircraft Auxiliary Power Units (APU). It is an engineered, porous material made of sintered metal fibers. The size of the fiber, porosity and thickness of the fibers combine to control the desired flow and sound absorption. To enhance the structural properties, the metal fibers may be reinforced by sintering to screen mesh or perforated plate.

Product Features

- High temperature resistance – FELTMETAL™ enables hot gases to be expanded gradually, thereby reducing turbulence and the amount of noise generated

- Optimum performance – Accomplished through acoustic impedance matching

- Readily cleanable – Simple cleaning operations and a material that is highly resistant to any performance degradation from numerous freeze/thaw cycles

- Excellent erosion resistance – Long service life

- Low non-linearity factors – Very effective resistance to high pressure waves/distortions

- Exceptional performance at high frequencies – Able to target nuisance frequencies (e.g. buzzing, humming, honeybee sounds that emanate from drones)

- Corrosion resistant – Resistant to aggressive cleaning agents

- Reliable performance in wet conditions – The material porosity allows the sound waves to push out any trapped liquids

Industries and Applications

- Commercial and Business Aircraft – APU inlet/exhaust and ECS ducting

- Human Spaceflight: Acoustics and Noise Control in Space Crew Compartments

- Industrial: Manufacturing Machinery and Heavy-duty HVAC Systems

Properties and Technical Information

- Fiber Dimensions

FELTMETAL™ Acoustic Media is produced from fibers having diameters ranging from 50 to 150 microns. Finer fibers offer the advantage of lighter weight and lower non-linearity factors.

- Extreme Temperature Performance

- Austenitic stainless steels (Types 316L and 347) for service temperatures up to 932˚F (500˚C)

- FeCrAIY for temperatures up to 2012˚F (1100˚C)

- How FELTMETAL™ Acoustic Media Works

When a sound wave is reflected from a hard surface of a silencer, constructive and destructive interference waves occur. If a porous material is placed across the wave pattern, the movement of air molecules through the material is converted to heat, resulting in a reduction in sound intensity. This reduction is highest if the material is placed at a location where the air molecule velocity is a maximum ¼ of the wavelength. The flow resistance of the porous material is critical to the efficiency of the attenuation process—if the resistance is too high, then the material acts as a hard surface and reflects the sound. But if the resistance is too low, then the sound wave travels freely through the material. In either case, the sound attenuation is less than optimal. We can help you find the optimal attenuating solution.