PTL Transport: Advancing Hydrogen Production

Taking What We Know and Making Something New

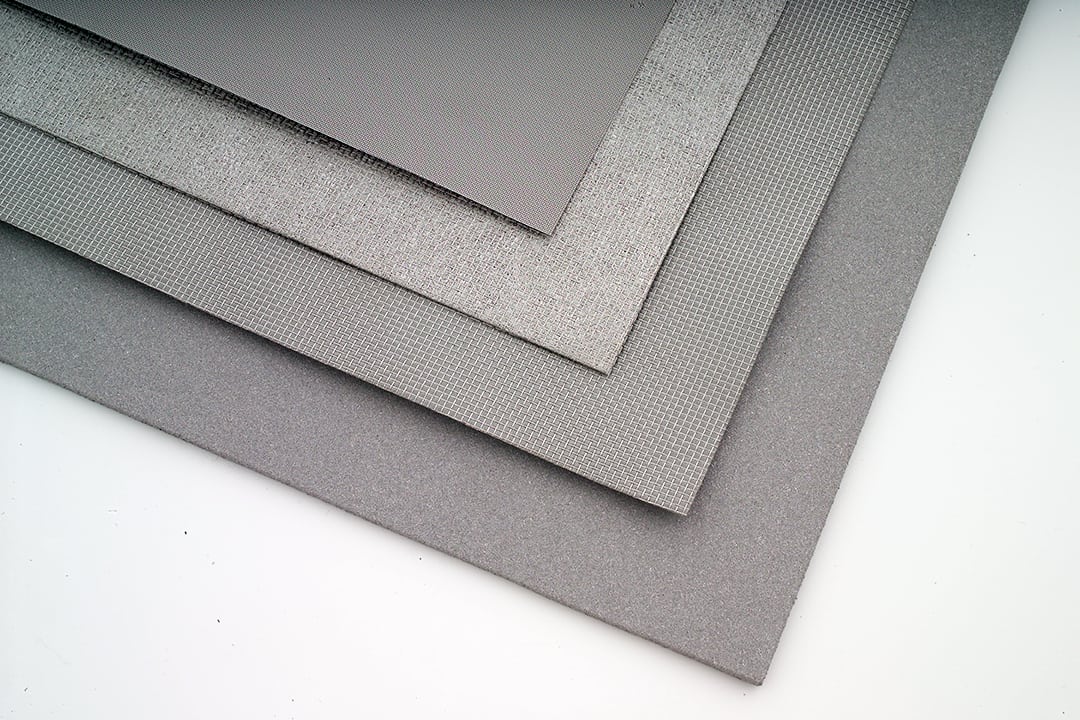

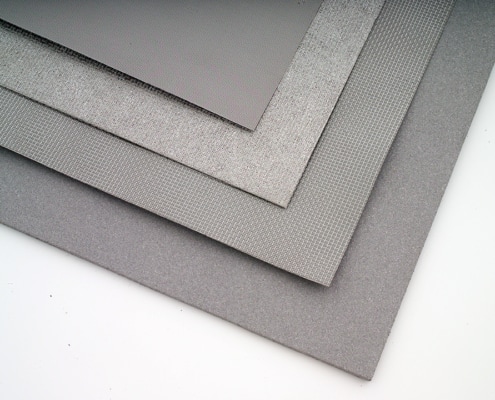

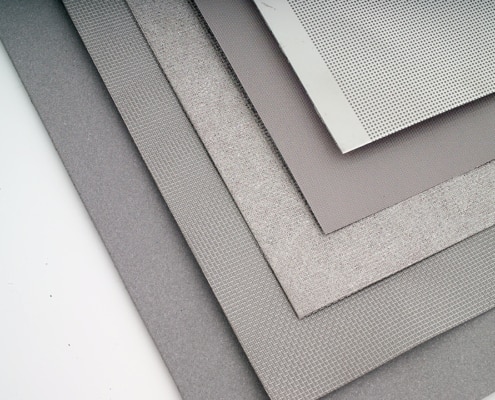

Technetics is taking over 50 years of experience manufacturing FELTMETAL™ products for the Aerospace industry and “transporting” it to Green Hydrogen. Through partnerships with universities and industry partners, we are developing various Porous Transport Layer materials to meet the needs of various applications.

Features

- Voltage required to produce 1A/cm2 (refer to table below).

- Low contact and ohmic resistance.

- Low variation in steady-state (operational stability) response over time.

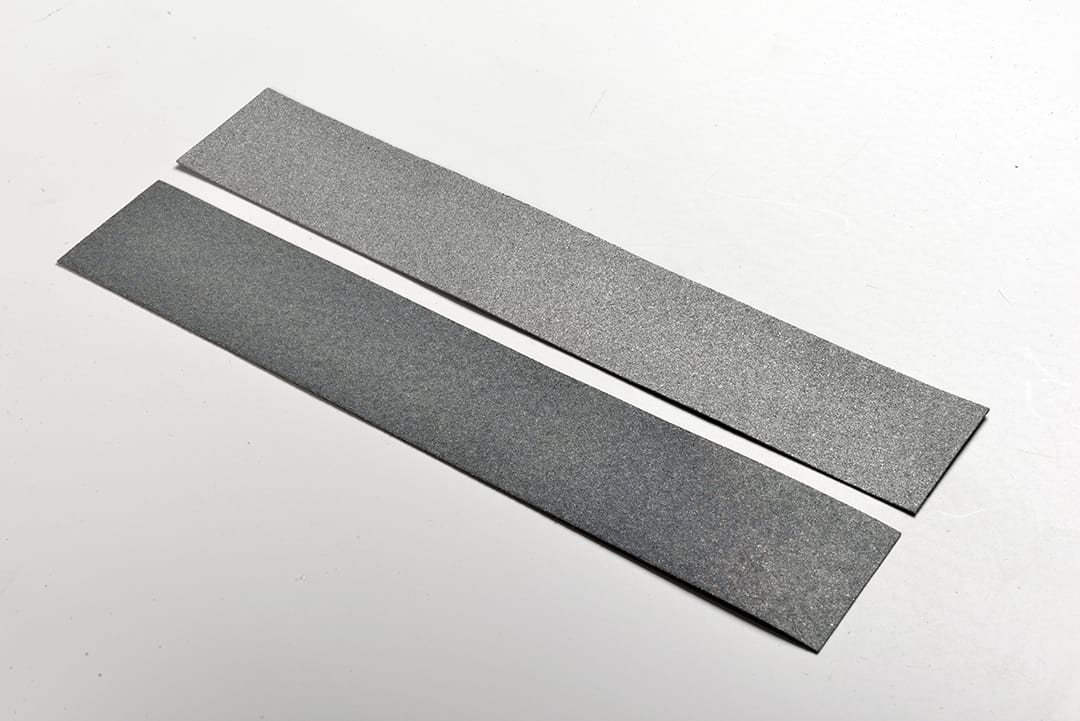

- Can tailor porosity and thickness to your application needs (find the right balance between “bubble” removal and contact resistance, length of diffusion and mechanical strength).

- Smooth surface allows for better contact with catalyst layer.

- Longer life in highly corrosive environment compared to carbon paper.

Material Properties

- Material: 347 Stainless Steel, Hastelloy-X, FeCrAlY (please contact us for other material options)

- Density: Any density between 18% and 75%

- Minimum Thickness: 0.007 [180 microns]

- Gradient (2-layer) density materials in development

What Is A Porous Transport Layer?

A Porous Transport Layer is the layer in an Electrolyzer stack that allows for the removal of oxygen gas from water during the Electrolysis process. It must also provide good electrical conductivity and operational stability over time.