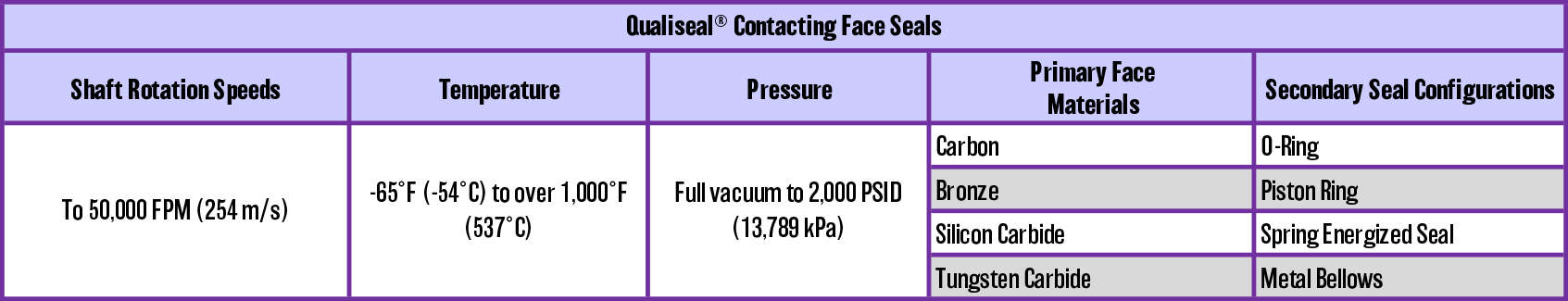

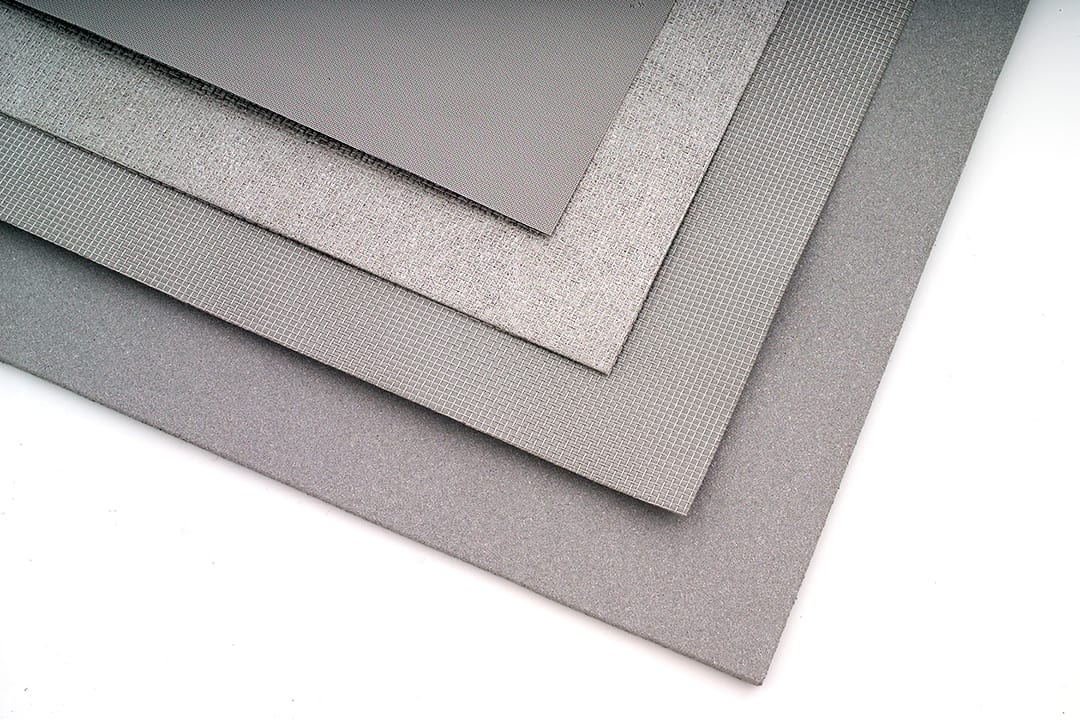

Qualiseal® Contacting Face Seals

Pushing the outer limits of speed and vibration with your critical application? We have two words for you. No problem. Qualiseal® Technology contacting face seals are known for versatility and exceptional performance across a wide range of demanding aircraft and industrial applications. They are designed for optimum performance where high speed and vibration are the norm. As the stationary portion of a seal assembly, contacting face seals are generally paired with a rotating mating ring, bearing or shaft. The seal face in the stationary portion provides the low-friction wear element that rides on the harder wear-resistant mating surface. The seal face and mating surfaces are typically lapped flat to within 0.0000348 inches (3 helium light bands), which provides virtually leak-tight sealing between the sealing interface. With the aid of Finite Element Analysis (FEA), mechanical face seal design at Qualiseal® Technology is optimized to meet or exceed the most extreme unit operating conditions, with long life and reliable performance.

Features & Benefits

Benefits:

- Achieve low leakage rates while managing axial shaft movement

- Easy, fast installation minimizes downtime and maintenance costs

- Designed to tolerate pressure reversals

Features:

- Can utilize either an O-ring on the outer diameter in a slip fit application or can be designed to press-fit into the seal bore of your unit

- Unbalanced or balanced designs

- Several elastomeric compounds, metal bellows or spring energized secondary sealing options are available for a variety of fluid and temperature applications

- Take-apart or unitized seal design

- Seal designs incorporate seal face material grades to encompass a wide range of applications, including high-pressure velocity (PV) or extreme vibration applications

- Available in Carbon, Bronze, Silicon Carbide, Tungsten Carbide