Technetics Provides Optimal Sealing Solution

Why Technetics HELICOFLEX® Delta seal was the perfect match for Berkley National Laboratory

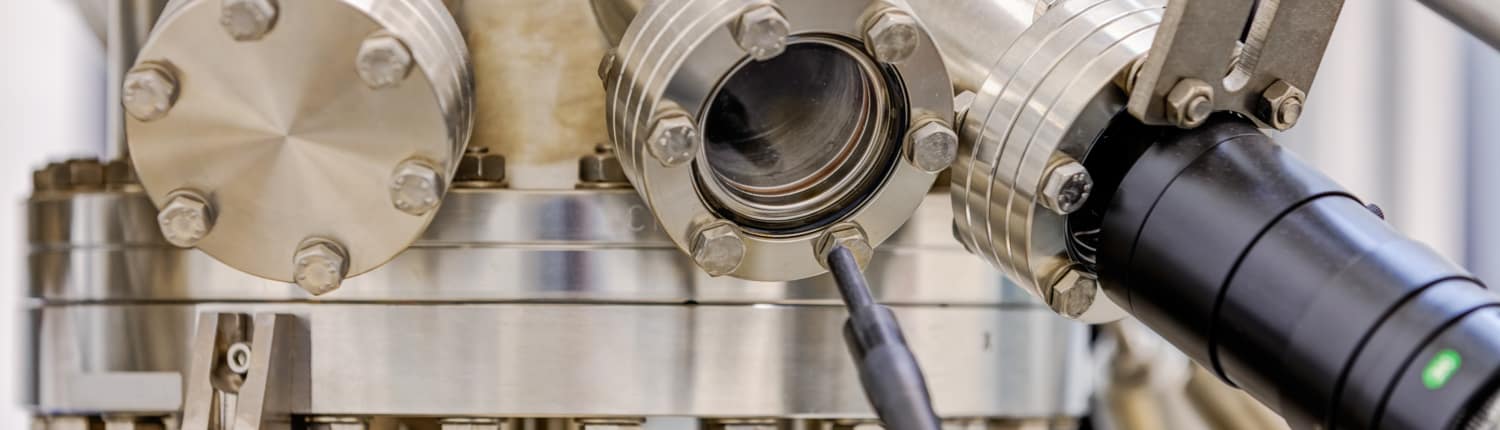

The Advanced Light Source is a research facility at Lawrence Berkley National Laboratory (Berkley Lab) working to advance science through its synchrotron light source capabilities. As a part of its Advanced Light Source Upgrade, Berkley Lab needed a sealing solution for its accumulator ring. The upgrade called for a UHV sealing solution appropriate for a synchrotron, with a seal located at the Beam Position Monitor (BPM) housing. The specifications for the application included a leak rate of 1×10-9 cc/sec He atm and temperatures of 25ºC operating and 180ºC bake-out for 1 hour each startup. Furthermore, Berkley Lab required 4 seals for each of the 72 assemblies of the seal, for a total of 288 seals needed for the initial startup of this application.

Due to the existing relationship between Berkley Lab and Technetics Group as well as Technetics’ involvement for several years in the Advanced Light Source “Kicker Box” assembly, the expertise and industry experience of Technetics was trusted for this application. After being invited to conduct a metal seal educational presentation, Technetics received the Accumulator Ring BPM application from Berkley Lab.

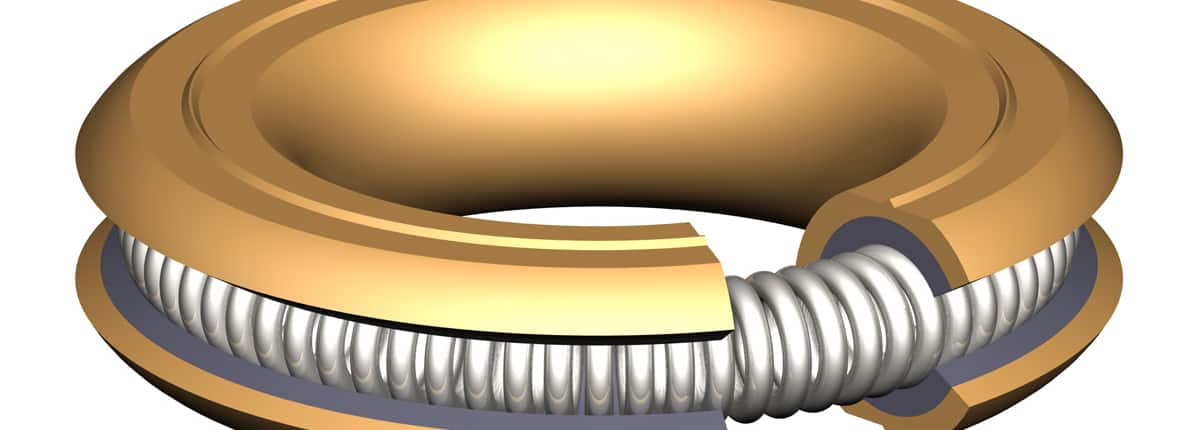

The HELICOFLEX® DELTA seal was identified as an optimal solution for this application. It incorporates two small ridges, or “Deltas,” on the face of the seal. The high-contact stress in the seal track makes the HELICOFLEX® DELTA seal an excellent choice for ultra-high vacuum applications that require ultra-low Helium leak rates. After the prototype order was received and pump down testing successfully completed, Technetics received additional prototype orders with the expectation of MRO demands every 2 years.