HELICOFLEX® DELTA – High-Performance Metal Seals for Ultra High Vacuum Environments

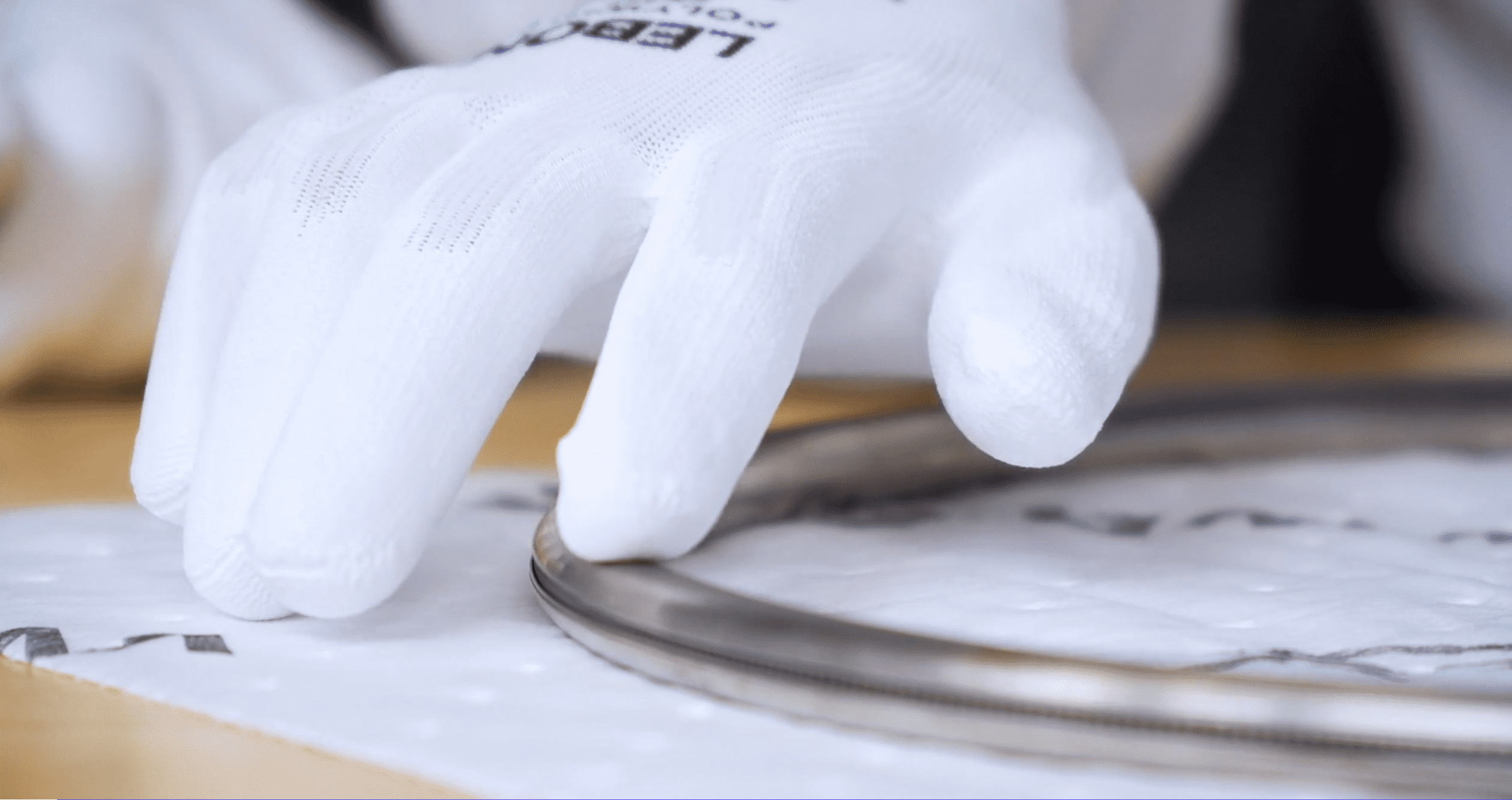

The HELICOFLEX® DELTA seal is a member of the HELICOFLEX® family of spring-energized seals. It is a unique sealing solution using two small ridges or “Deltas” on the face of the seal. The load required to plastically deform the jacket material is greatly reduced by concentrating the compression load on the Deltas. The resulting high-contact stress in the seal track makes the HELICOFLEX® DELTA metal seal an excellent choice for ultra-high vacuum applications that require ultra-low Helium leak rates. There is typically no risk of damaging the flange sealing surfaces as long as the minimum hardness requirements are maintained.

Features & Benefits

- Highest sealing level performance on the market, depending on the seal jacket, the cavity/flange finish, the bolting, the hardware robustness and the cleanliness level

- Ø 1.9 to 6.4 mm cross-section

- Adaptable to all types of sealing surfaces

- Adaptable to all flange standards (PNEUROP,ANSI, ISO, and more): no limitation on flange materials, allowing the seals to be used on metal flanges as well as ceramic, glass-lined and glass flanges

- Wide material choices: from standard to specific and rare (see details below in “Specifications” section)

Product Applications

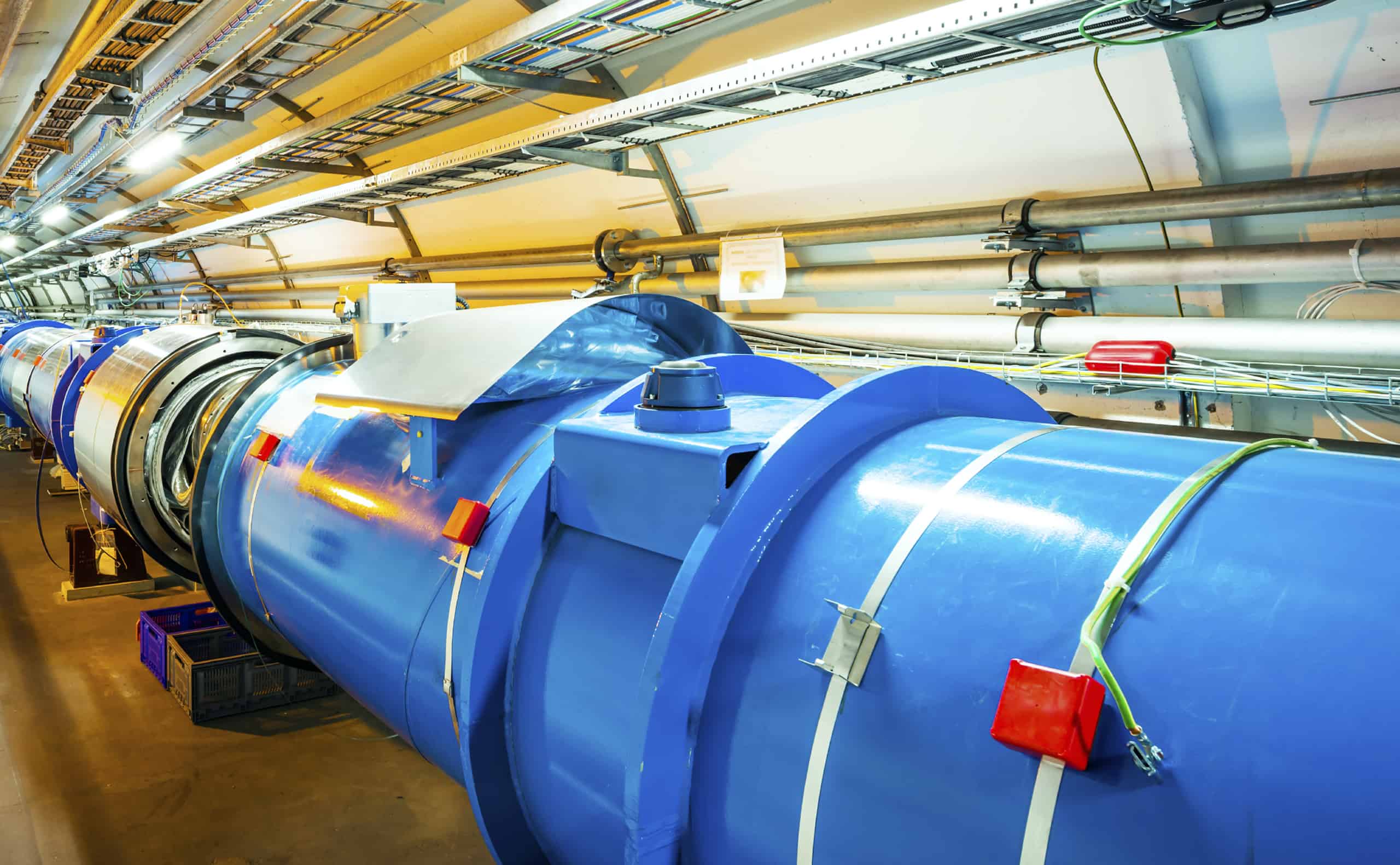

- Ultra-high vacuum

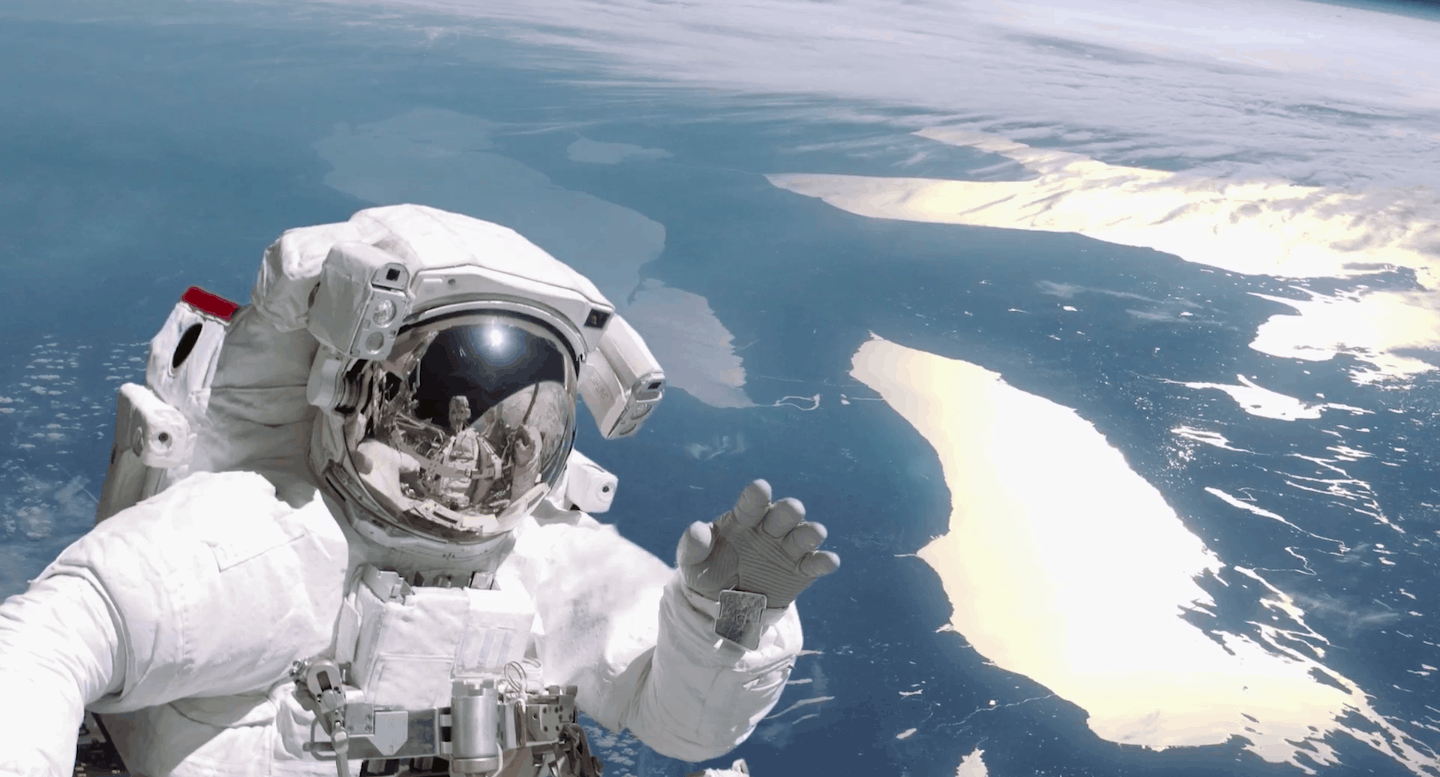

- Space

- Semiconductor

For the following industries:

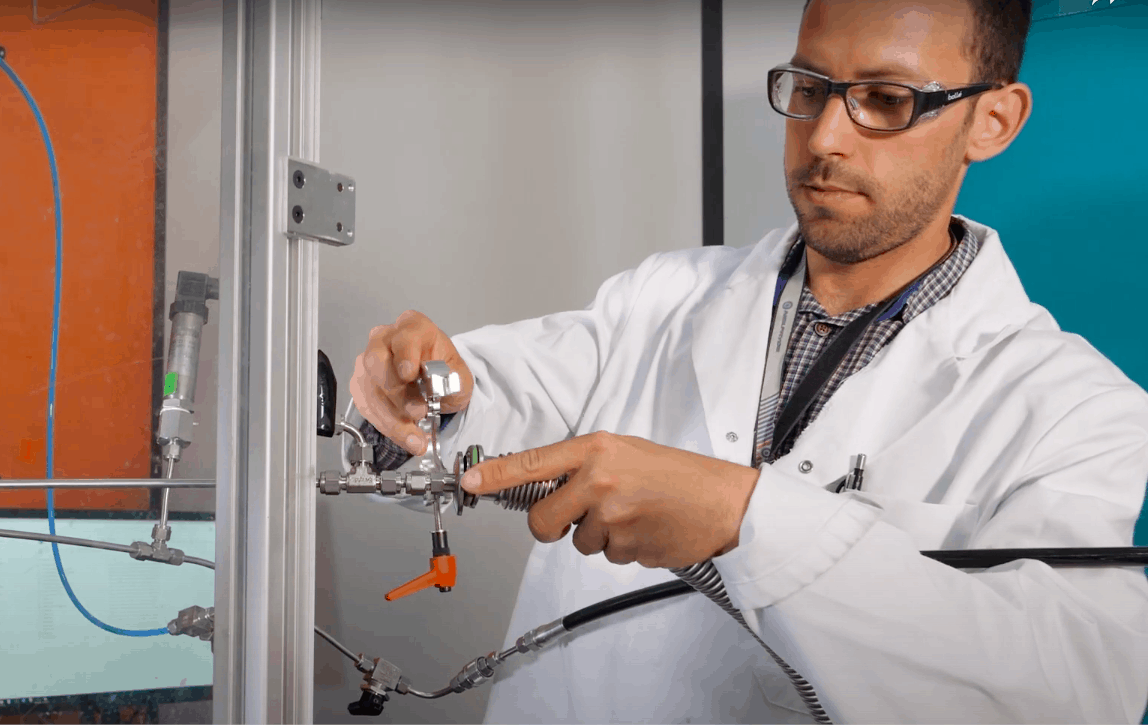

- Research laboratories

- Fusion