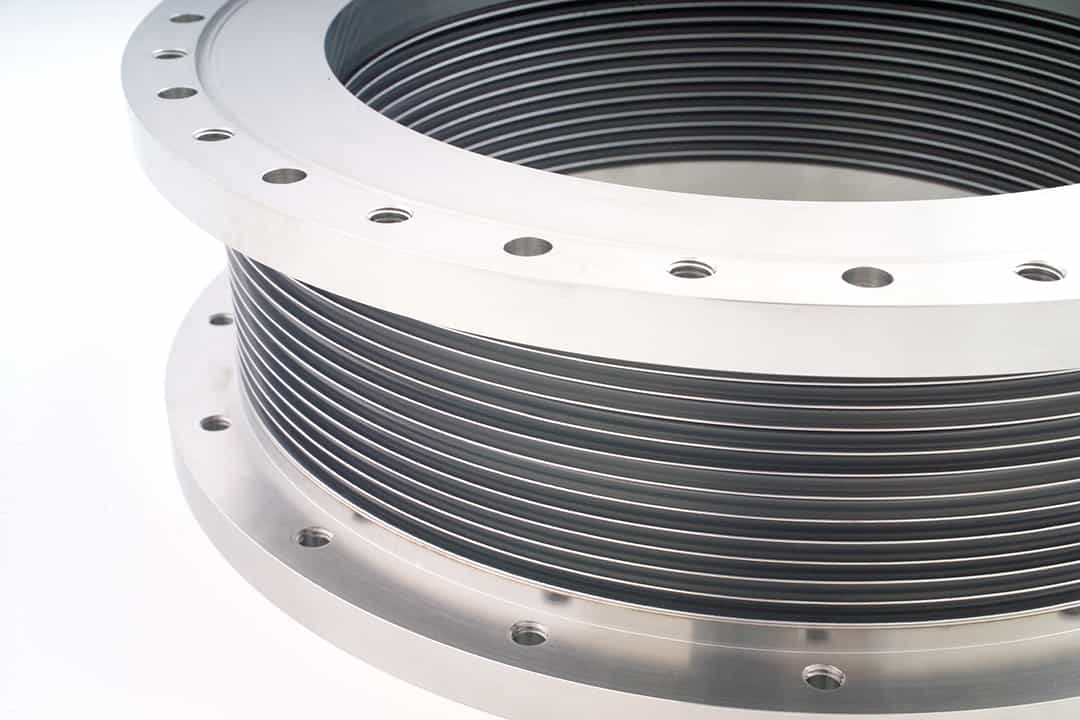

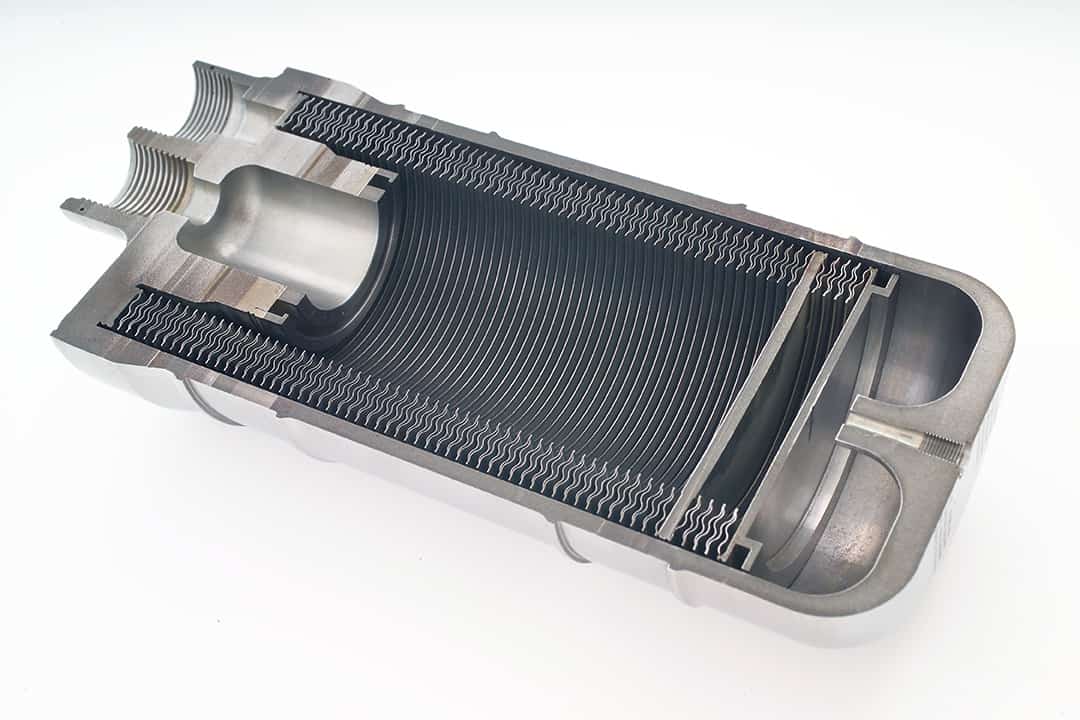

Technetics Group is a world leader in the design, production, and application of high precision sealing products incorporating edge-welded metal bellows. As a leading metal bellow seal manufacturer, we are continually working to engineer new and unique design solutions that solve critical needs and give you confidence when you need it most. We help ensure your equipment performs better, and can satisfy your most stringent product requirements.

About Technetics Group Metal Bellows

Edge-welded metal bellows provide superior stroke capabilities and more precise spring rates than formed bellows, giving you greater flexibility and control in the smallest possible spaces. Because we manufacture our edge-welded metal bellows by welding both the inner and outer diameters of the bellow plates, we can produce them in a nearly endless variety of materials, unlimited by material ductility.

Product Features

- Wide range of material and configuration options

- High spring rate, very low tolerance for axial displacement

- Low magnetic permeability

- Corrosion-resistant

Industries and Applications

- Aerospace for use in reservoirs, toggle switches, cold plate assemblies, fuel drains, and engine kiss seals

- Oil & gas for use in actuators, connectors, couplings, feed-throughs, gas lines, reservoirs, and sensors

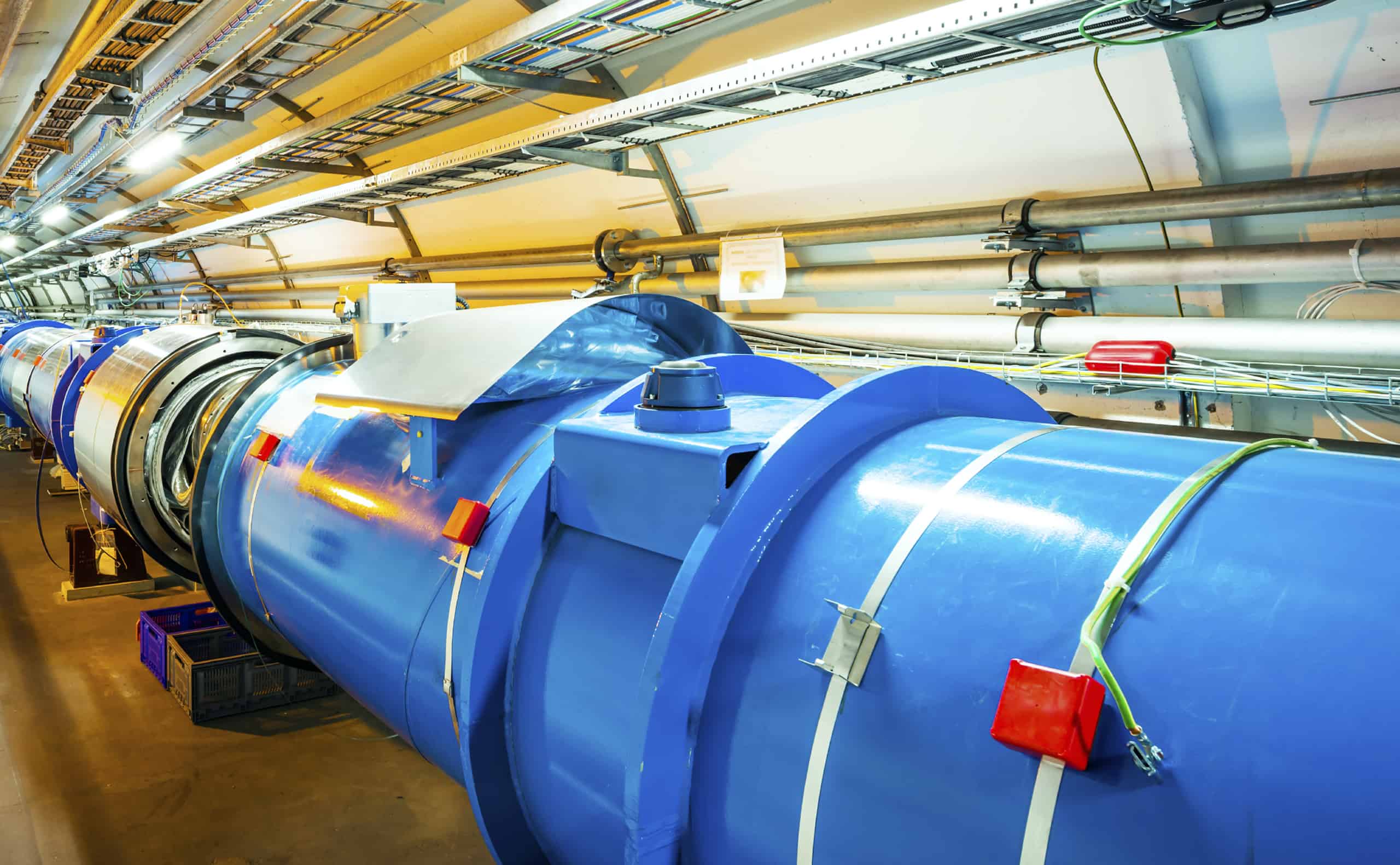

- Semiconductors for use in actuators, beamlines, connectors, feed-throughs, leak detectors, sensors, gate valves, wafer handlers, and pedestal lift assemblies

- Medical for use in batteries, cardiovascular devices, implants, drug delivery, monitoring devices, vacuum pumps, and valves

Properties and Technical Information

- Technical Specifications

- 0015″ to 0.02″ diaphragm thickness

- 1/4″ to 18″ outer diameter

- Vacuum pressure to > 1,000 psi

- Cryogenic temperatures to 1800°F (982˚C)

- Expertise and Design

Our engineers will design a robust product that achieves the highest life-cycle possible for your application while addressing all of your operating parameters. This includes stroke (lateral, angular and/or axial movement) pressure (internal and external), temperature, and environment. Linear and thermal movements, vibration isolation, and assembly offsets can all be accommodated with BELFAB®-designed bellows devices.

- Comprehensive Services

Technetics Group offers contract assembly services including design, fabrication, welding, upper-level assembly, testing, and packaging.

- Clean Room Assembly and Certification

A certified Class 100/ Class 1,000/ Class 10,000 cleanroom assembly environment is available as required. As an ISO 9001-certified organization noted for world-class cellular manufacturing, Technetics Group has built its reputation on a foundation of total quality achievement.