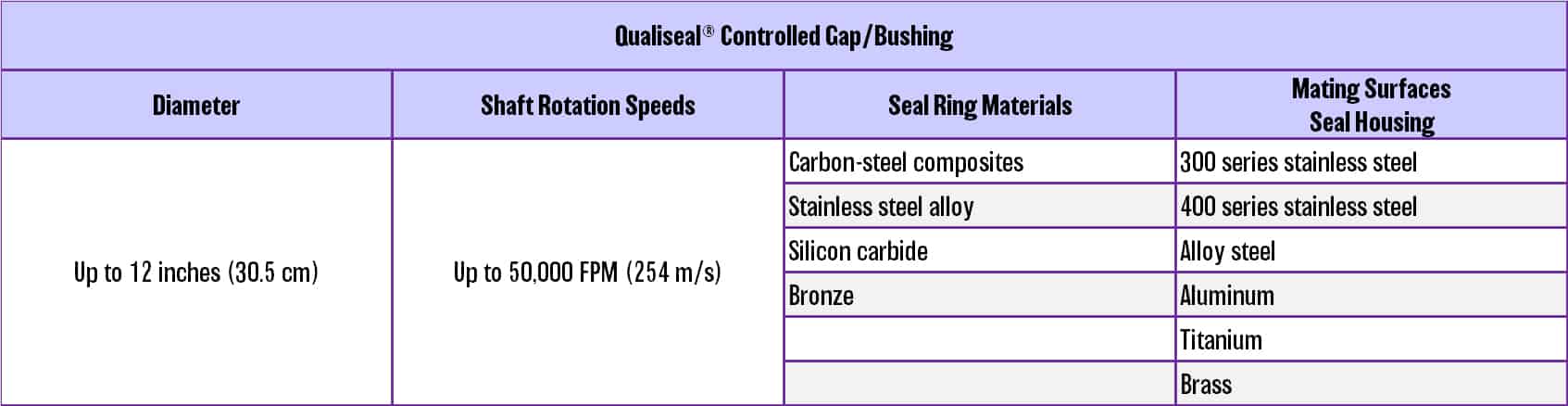

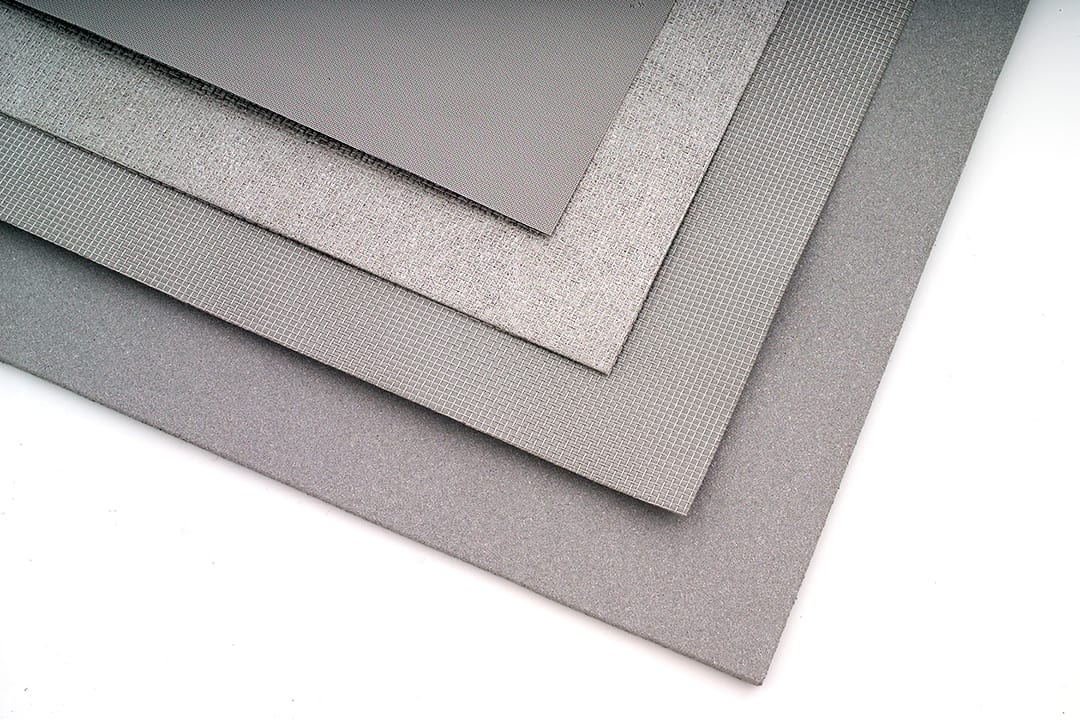

QUALISEAL® CONTROLLED GAP/BUSHING

Really two pieces in one, Qualiseal® Controlled Gap/Bushing seals are the best solution when pressure is an issue.

Controlled gap or bushing seals are comprised of a carbon insert that is shrink-fitted into a separate retaining band. This floating circumferential ring assembly grows at a rate similar to that of the shaft when exposed to elevated temperatures.

Under normal operating conditions, the pressure on the airside is higher than the pressure on the oil side. This creates some air leakage through the controlled gap between the carbon ring and shaft. The differential air pressure, along with the spring load, provide the closing force necessary to maintain contact between the carbon and housing secondary sealing face. Meanwhile, the shaft turns freely within the carbon ring.

The seal design also features a unique stabilizer ring with fins which minimize stress on the carbon ring, thereby maintaining the roundness of the circumferential ring assembly. The dimensional tolerance of the critical inside diameter of the bushing ring is tightly controlled to minimize leakage variations.

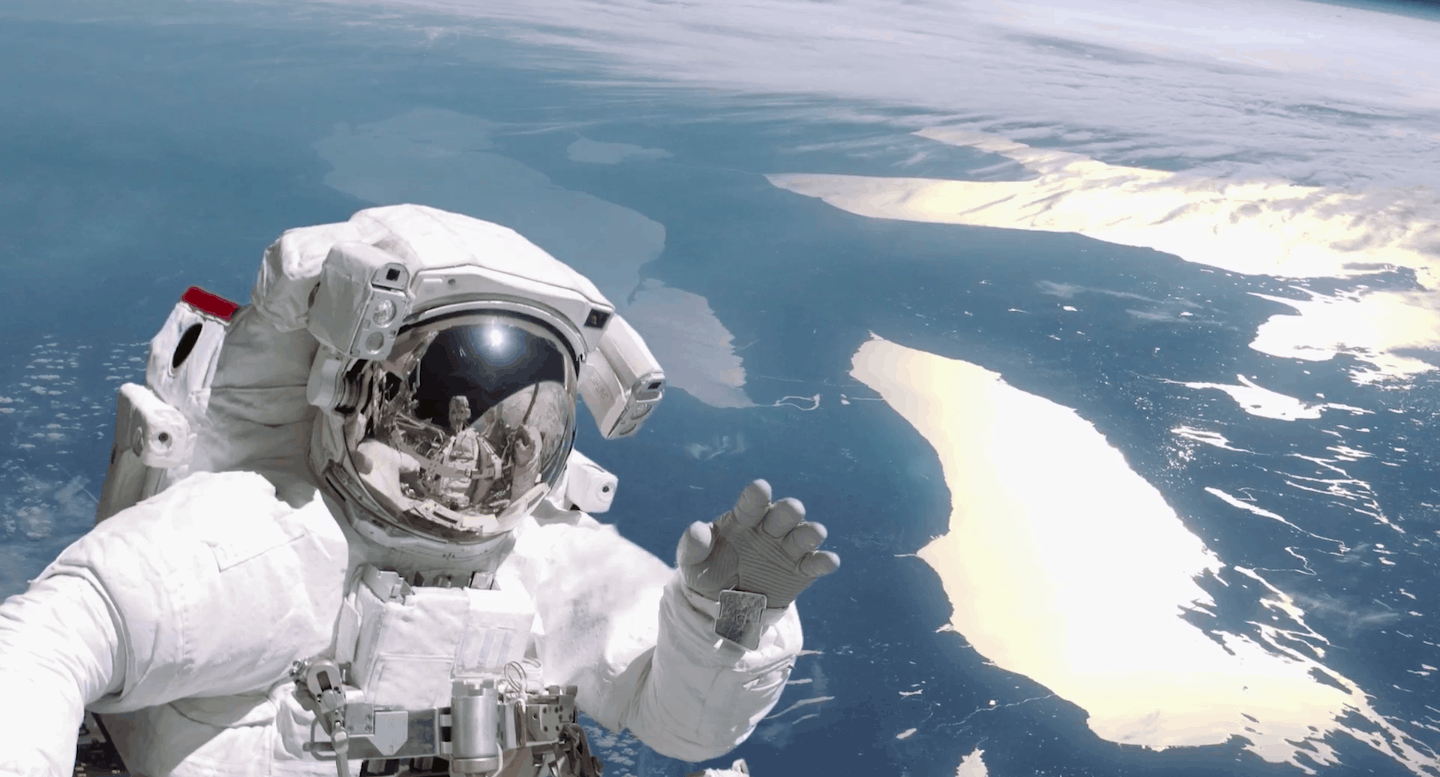

Product Applications

- Aerospace Industry

- Industrial Industry

Ideal For:

- High-pressure applications

- Also suitable for sealing low-pressure liquids

Features & Benefits

Benefits:

- Minimal leakage in an exceptionally wide temperature range

- Tolerance to unlimited shaft axial movement

- Very long life

- Very low heat generation

Features:

- Rides on a buffer that centers the ring and minimizes seal-to-shaft contact

- Available in a wide variety of materials suitable to a broad range of applications

- Often paired with other seals to create sealing systems that meet demanding requirements

Design Configurations:

- Single seal for dual pressure conditions

- Spring-loaded double back-to-back seal

- Separable designs to facilitate replacement and/or rework of internal components

- Double tandem seal arrangement for sealing a combination of liquids and gases

- Multiple labyrinth ring assemblies

- Housing for mounting directly onto equipment case

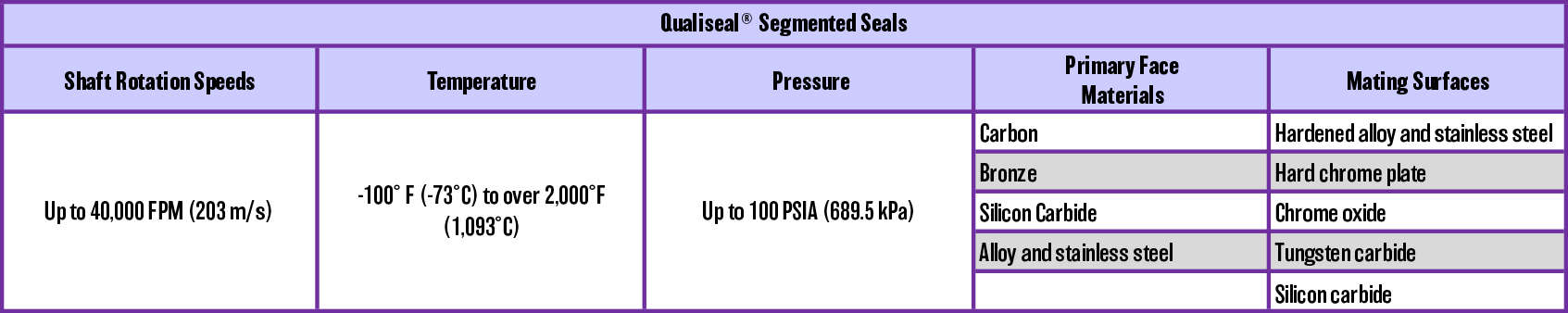

QUALISEAL® SEGMENTED SEALS

Segmented seals ride directly along the shaft and are primarily used in low-pressure applications.

These seals contain a series of segmented carbon rings which contact the shaft or rotor. Segments inside the seal housing are kept in the proper location by anti-rotation keys or pins. A secondary seal is formed by the axial spring loading of the seal rings against the internal surface of the housing face. During movement, a continuous seal is always in contact with either the primary or secondary sealing surfaces.

Product Applications

- Aerospace Industry

- Industrial Industry

Ideal For:

- Gas seals and for sealing low-pressure liquids

Features & Benefits

Benefits:

- Tolerance to unlimited shaft axial movement

- Prevents oil and contaminant migration into the process gas side

- Leakage rates remain constant over the life of the seal

Features:

- Rides directly along the shaft

- Special gap segments permit the seal to adjust dimensionally for minimal leakage

- Compression and garter springs ensure that segments remain in contact with mating surfaces during low delta pressure and shutdown conditions

Design Configurations:

- Various seal ring segment configurations

- Pressure-balanced segments

- Fractured rings

- Multiple seal labyrinth

- Internally pressurized seal

- Internally vented seal