Semiconductor Manufacturing Chemical Delivery Case Study

The Challenge: Leak-Tight Storage and Transport of Highly Toxic Chemicals

The semiconductor manufacturing process requires the use of highly toxic chemicals. The chemical plant providing these chemicals needed a vacuum-tight seal to transport their product to the semiconductor processing location. The chemical container required a vacuum seal with a helium leak tightness seal and positive pressure. Due to the caustic nature of the chemicals, plastic seals are not a consideration.

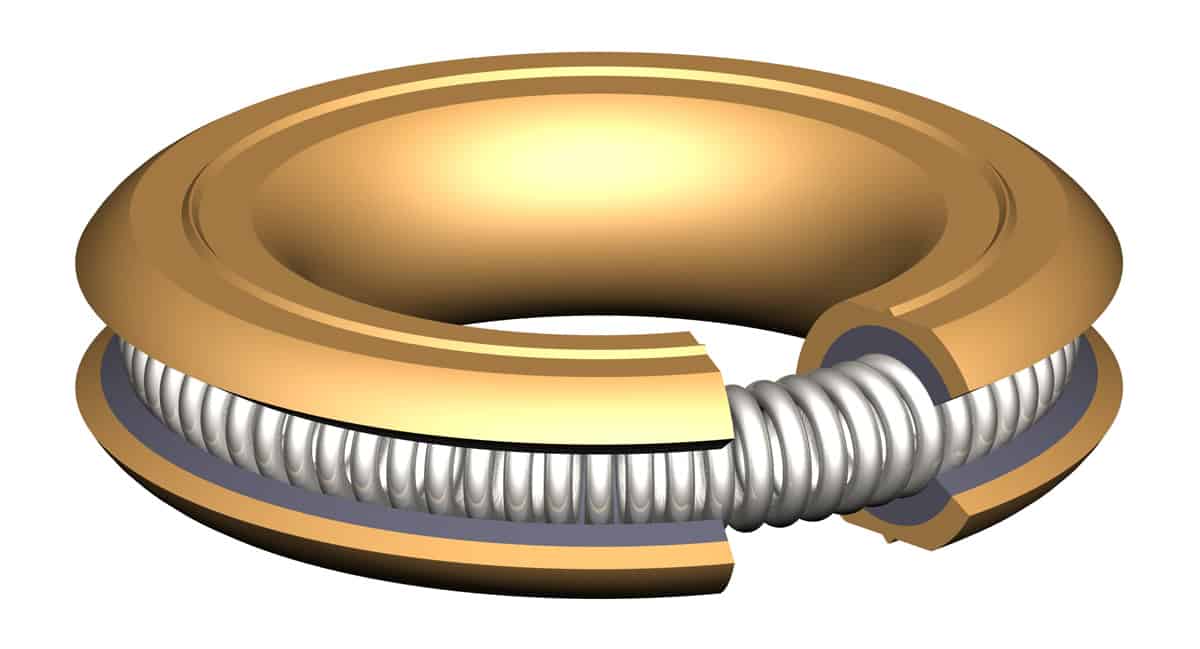

The Solution: A Highly Engineered Metal Seal, HELICOFLEX® DELTA

The HELICOFLEX® DELTA seal was identified as an optimal solution for this application. It incorporates two small ridges, or “Deltas,” on the face of the seal. The high-contact stress in the seal track makes the HELICOFLEX® DELTA seal an excellent choice for ultra-high vacuum applications that require ultra-low Helium leak rates. This solution achieves a 120 deg.C 2barG and helium leak-tight vacuum. The prototype order was received in 2017and testing successfully completed. Technetics continues to supply thousands of precision metal seals yearly to this satisfied customer as the demand for semiconductor processing continues to boom.