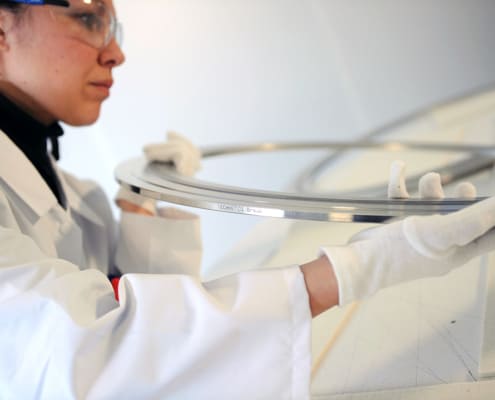

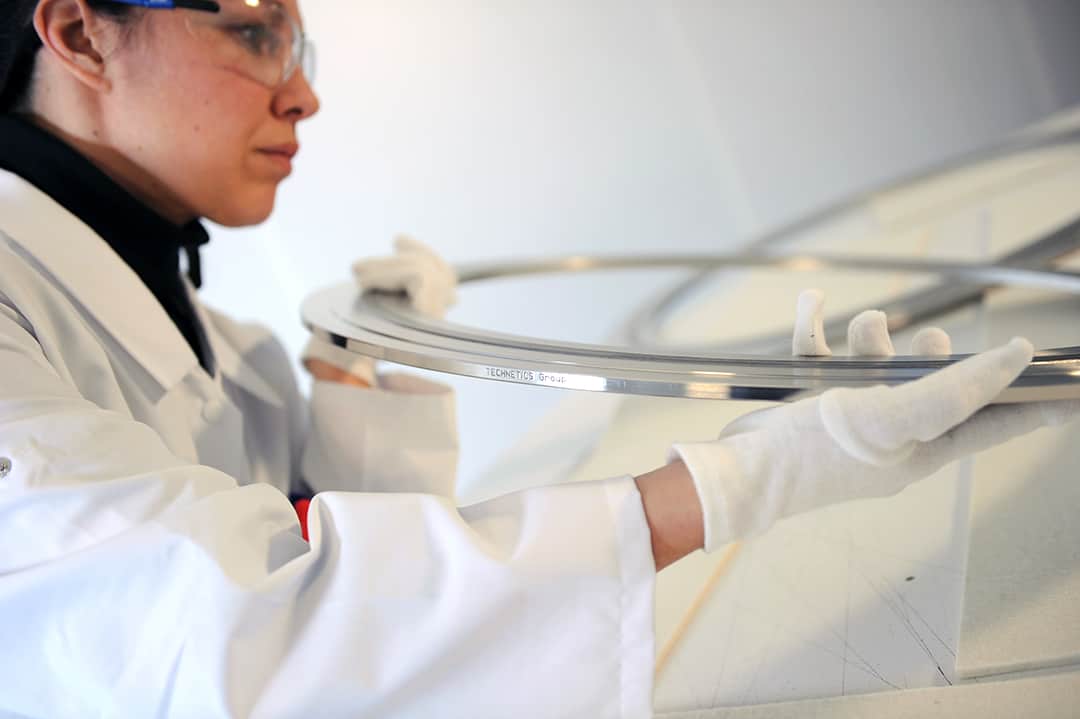

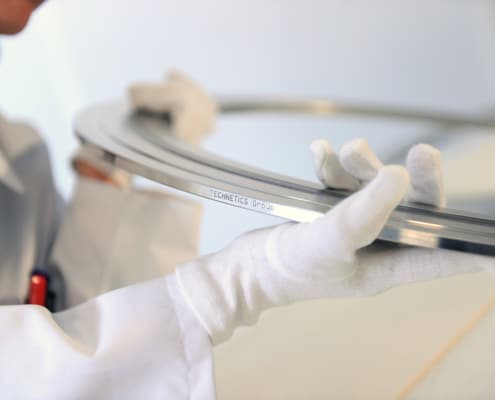

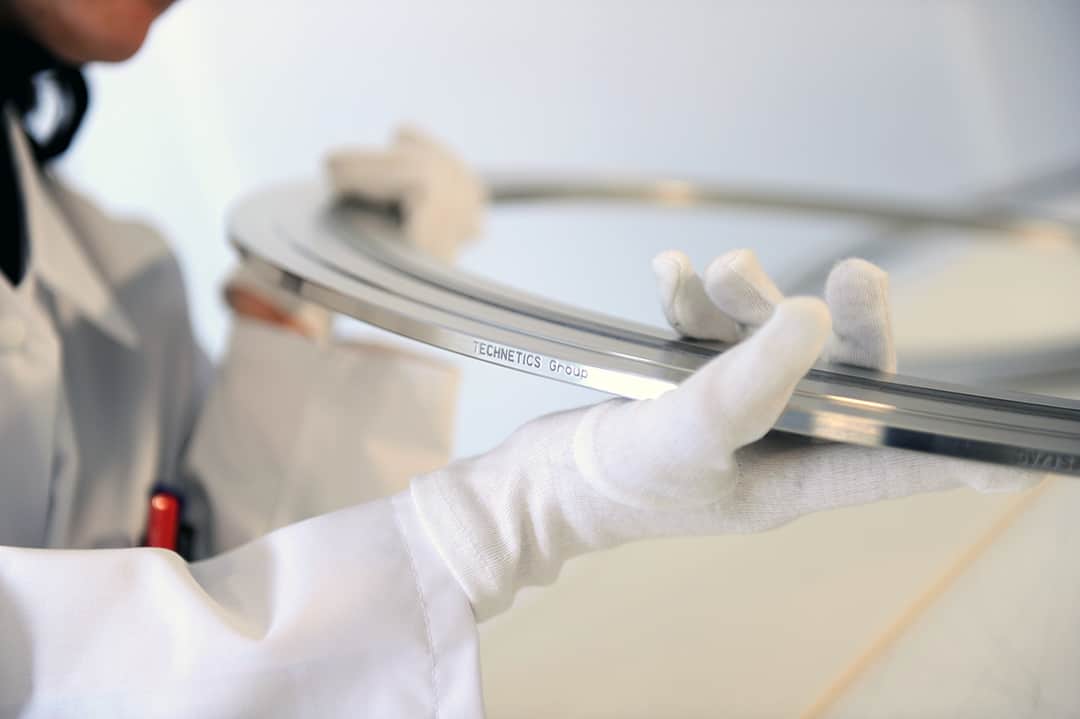

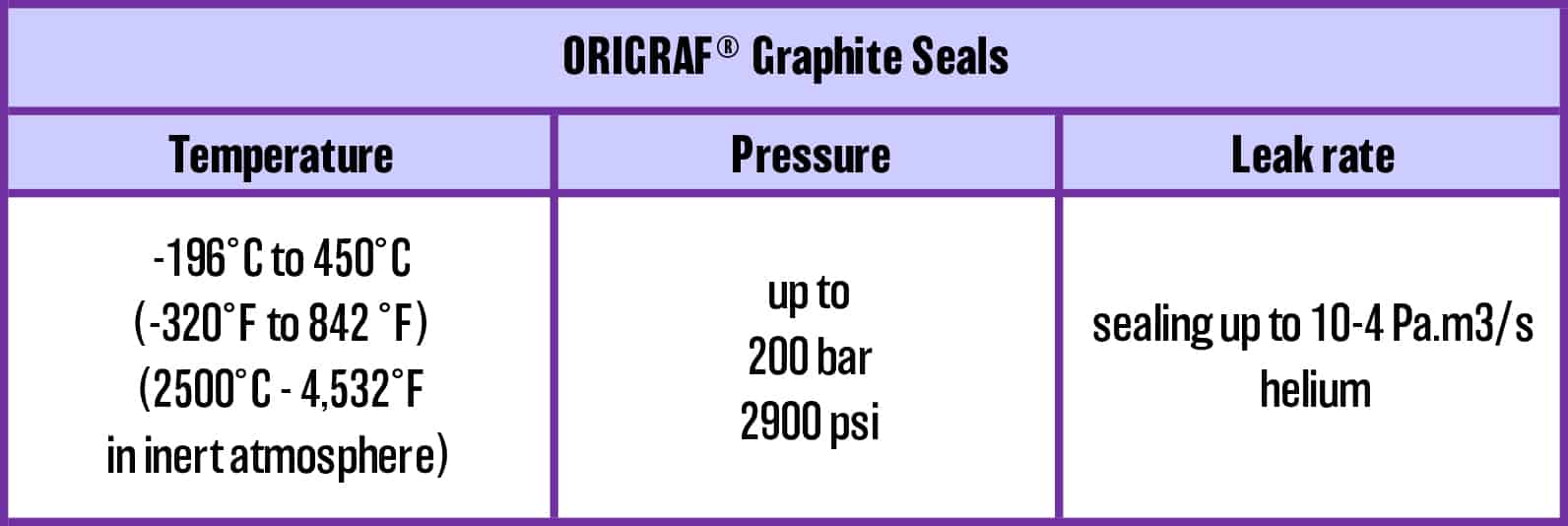

ORIGRAF® Graphite Seals

The ORIGRAF® seal provides a lasting high-performance sealing solution for all industries. It can be specifically designed for extreme thermal & pressure cycles ensuring higher safety in operation while optimizing total cost of ownership.

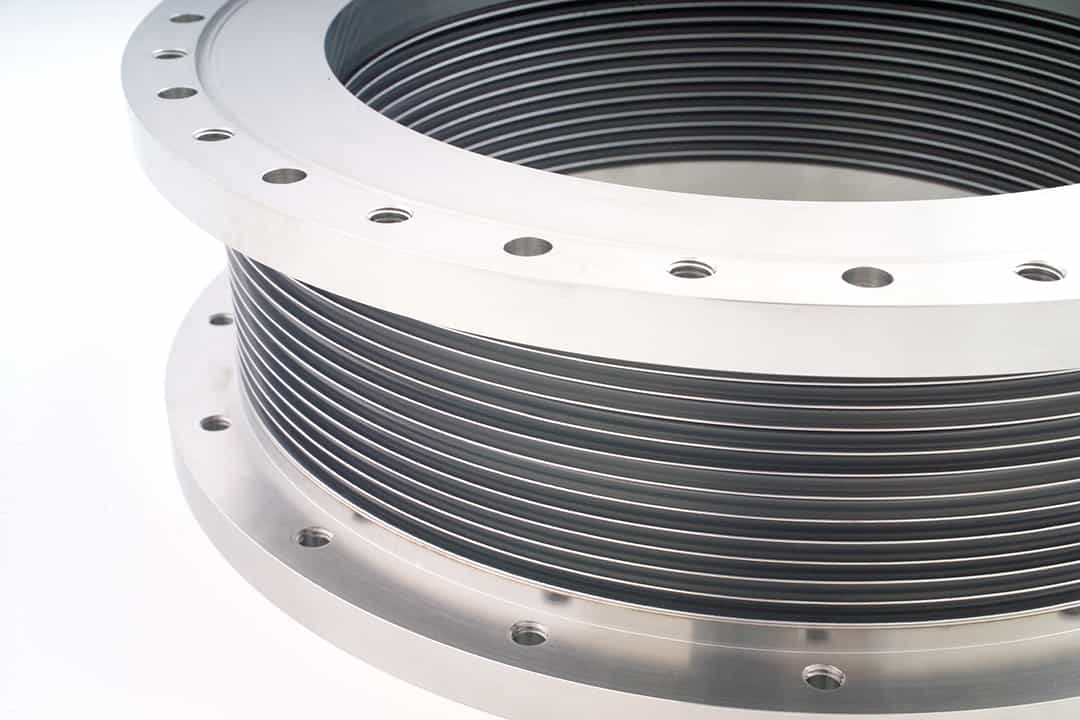

Unlike flexible graphite cut gaskets, the compression of the ORIGRAF® die-formed seal is limited by a mechanical stop: groove or inner and/or outer ring. In the case of assemblies subject to extreme pressure and/or temperature this design prevents excessive seating stress on the seal during transients.

This reliable and sustainable solution allows the optimization of overall operating costs, increasing the Mean Time Between Failure (MTBF).

Features & Benefits

- Excellent elastic recovery, capable of reaching 40% of compression recovery (spring back effect)

- Graphite spring-back effect serves the sealing function

- Adaptability to extreme thermal and pressure changes

- Chemical inertness: withstands most chemicals (mineral acids and solvents)

- Natural lubrication of the graphite: excellent resistance to radial movements of the flanges

- Can be adapted to damaged flanges

- Flexible graphite does not stick to the contact surfaces: can be easily removed

- Low creep and relaxation

- Withstand differential radial motion

Product Applications

ORIGRAF® seals are mainly used in applications servicing the following industries:

- Nuclear

- Chemical

- Petrochemical

- Aerospace

- Oil & Gas

The range of applications can be extensive, including:

- Steam equipment

- Heat exchangers/heaters

- Piping connection flanges

- Corrosive circuit

- Critical flange applications

- Boilers manways

- Fire safe requirements

- Alkylation units