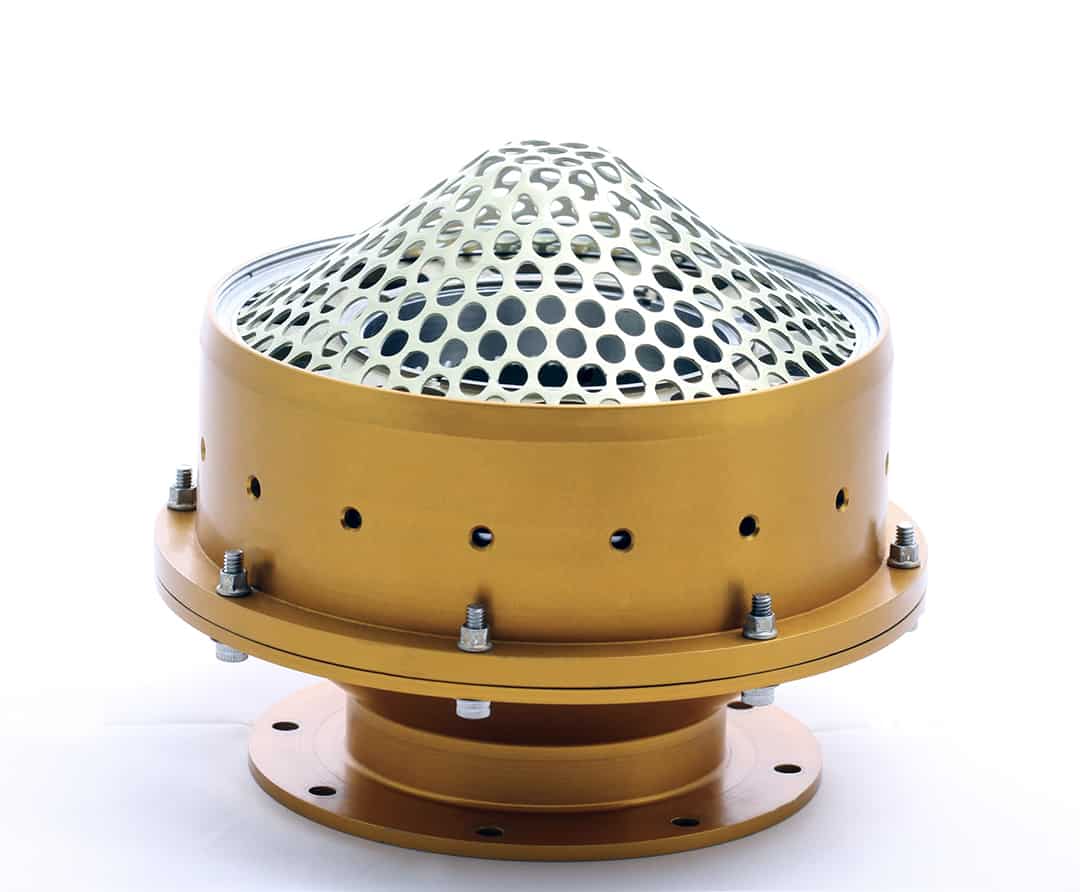

K-Port Metal Seals: Engineered for Safety

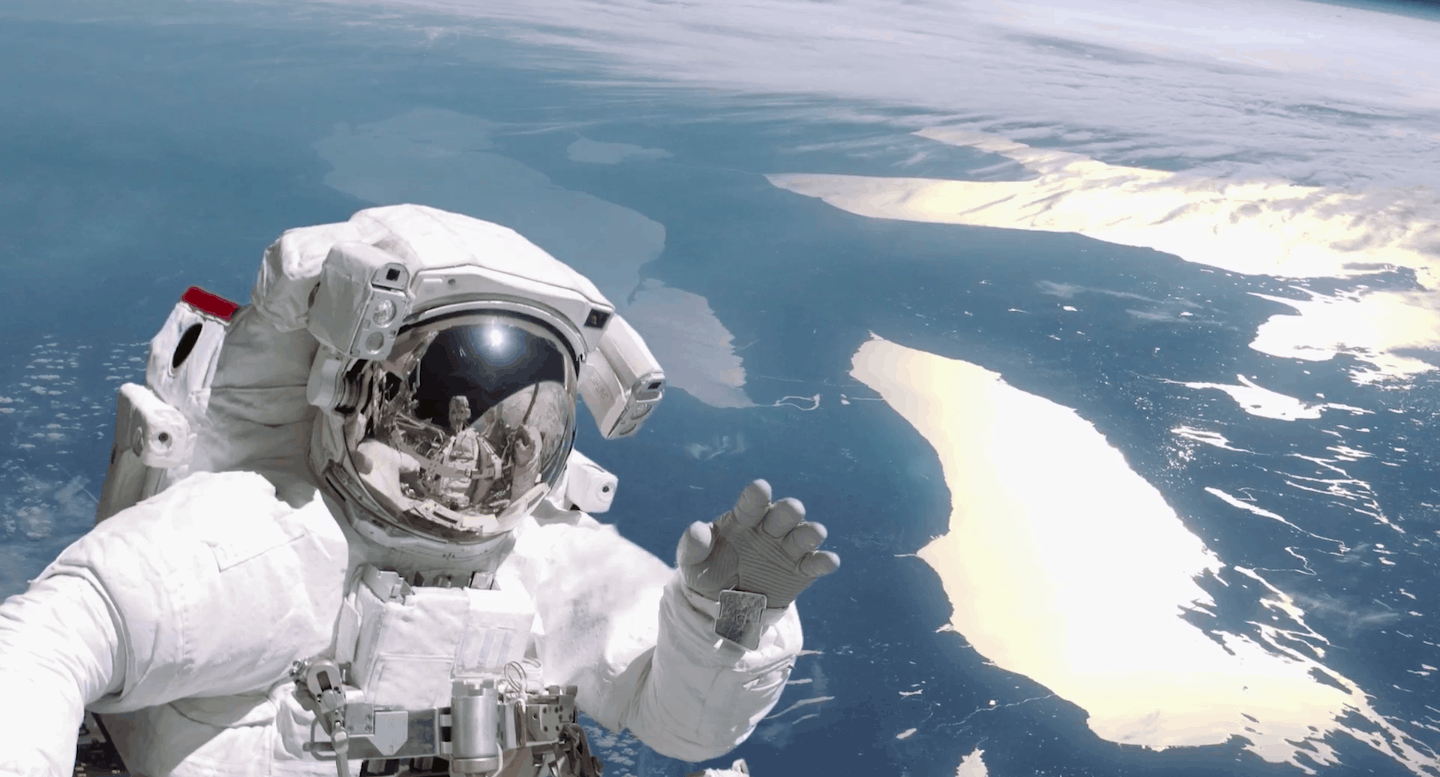

The Only Metal Port Seal Technology Approved by NASA for Human Spaceflight.

Flight Tested and Proven

Technetics K-Port Seals have an extensive pedigree with launch vehicle and spacecraft manufacturers all over the world.

Engineered for Safety

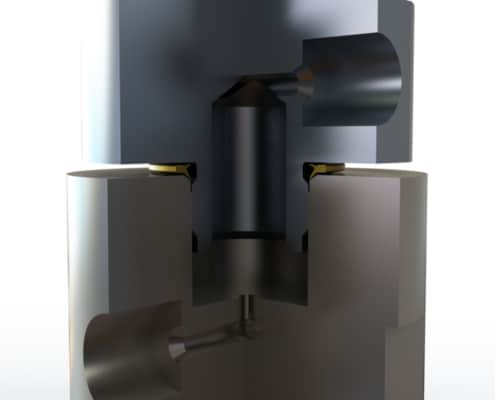

Technetics K-Port seals were designed to provide high performance sealing for AS5202 Port applications. Technetics’ unique K-Port seal design was optimized in-house by our expert engineering staff and validated by dozens of global spaceflight customers over hundreds of successful missions. With our K-Port Seal, you don’t just get a highly engineered seal, you get peace of mind.

Mission Critical Dependability

Reliability is of upmost importance when it comes to sealing. Backed by our quality management system and decades of space pedigree, Technetics K-Port seals are trusted by expensive payloads and more importantly, human flight.

To learn more about K-Port Seal Technology, download the brochure below. You can also contact us for a custom-engineered solution to your application or to request a quote.

Features & Benefits

Benefits:

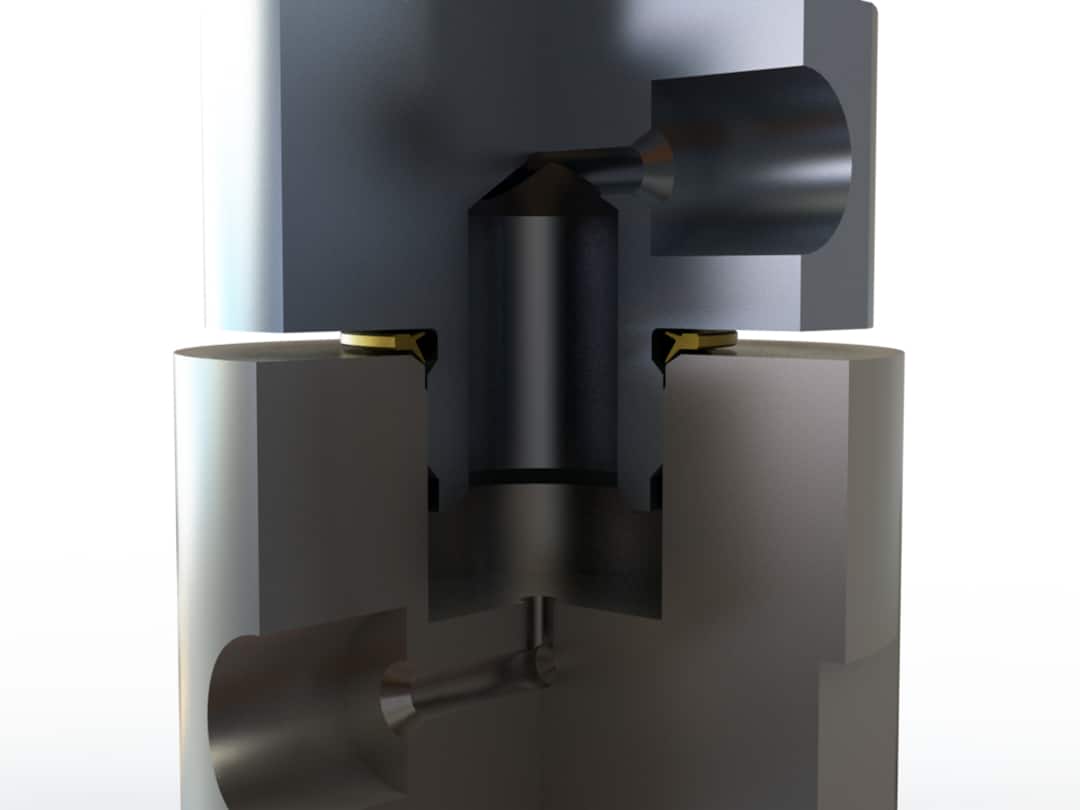

- Superior leakage control compared to c-ring or elastomer o-ring

- Sealing solution for AS5202 standardized fluid port geometries and port options

- Usable in much higher pressure and temperature environments as engine technology evolves

Features:

Platings and coatings: silver, gold, PTFE

Product Applications

High Temperature: Aerojet Rocketdyne | RS-25 Engines | “In addition to the K-[Port]seals, other external gaskets were tested, but none could match the high-pressure capability and reliability of the K-[Port]seals. The highest pressure tested with the K-[Port]seals was 12,000 psi. No leakage was seen with any of the K-[Port]seals.” – NASA Summary Report: High-Pressure Hydrostatic Testing of Spark Igniters for Rocket Engine Applications

Low Temperature: Selected by NASA and Boeing for use on cryogenic applications onboard the Space Launch System.

Aerospace Applications

- Cryogenic Fluid Management

- LH2 | −253 °C (−423.4 °F; 20.1 K)

- LOx Oxidizer | −183 °C (−297.4 °F; 90.1 K)

- Xenon Coolant | -271 °C (-456 °F; 1.8 K) , Methane, etc.

- Liquid Fuel Management

- RP-1 Kerosene, Hydrazine Nitrogen Tetroxide (NTO)

- Jet Fuels

- High Temperature Rocket Engine Sealing

- Hybrid Hydrogen Aerospace Engine Sealing

- Flow Control

- New Energies

- Oil & Gas