Engineered for Demanding Environments. Trusted When It Matters Most.

When your applications operate in high-stake, high-performance environments, you need sealing systems that deliver precision, reliability and peace of mind. At Technetics Group, our custom sealing systems and subassemblies are engineered to meet the toughest challenges — so you can focus on performance, not failure points.

Why Choose Technetics Sealing Systems?

- Precision-engineered for complex assemblies and best sealing performance

- Time-saving integration (following ALARA guidelines) that simplifies installation and maintenance and reduces downtime

- Proven reliability in extreme pressure or vacuum

- Built to specifications to meet your exact application and industry standards

From aerospace to nuclear, our sealing systems are trusted by engineers worldwide to perform when failure is not an option.

Integrated Solutions for High-Performance Applications

At Technetics Group, we offer a comprehensive range of sealing systems and subassemblies engineered for reliability, efficiency and ease of integration. Our solutions are trusted in critical environments where performance and safety are paramount.

Our Sealing System Solutions Include:

- KENOL® fittings for precision sealing through controlled plastic deformation

- Quick Disconnect Systems (QDSs) for rapid, space-saving flange assembly

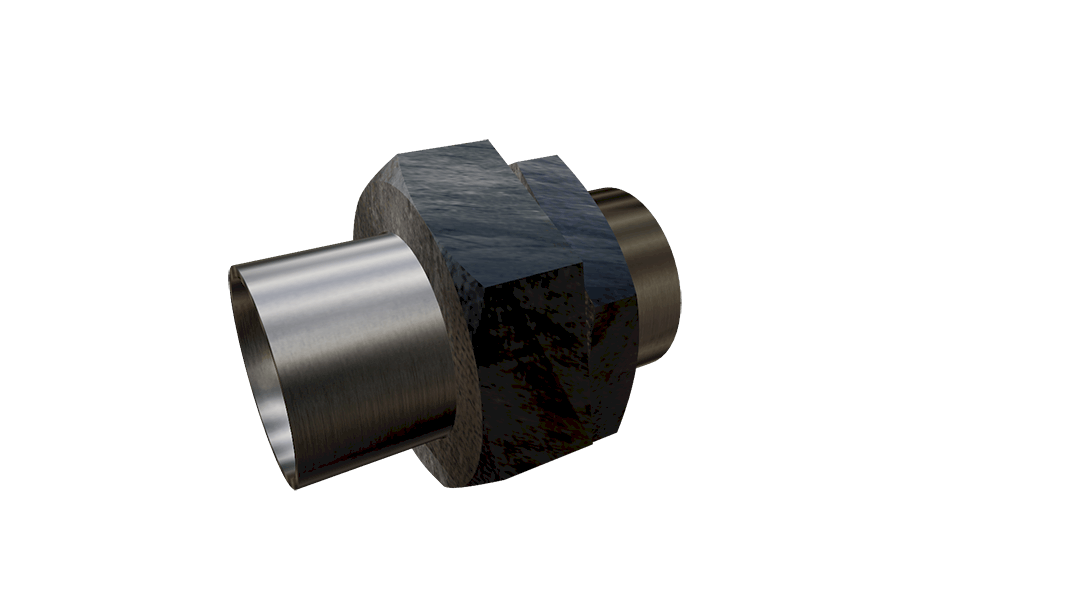

About KENOL® Fittings

Precision Sealing Through Controlled Deformation

KENOL® fittings deliver high-performance sealing by leveraging the principle of controlled plastic deformation. This design ensures a tight, reliable seal even under extreme pressure and temperature conditions — ideal for applications where leak prevention is critical.

About the Quick Disconnect System (QDS)

Fast, Compact and Radiation-Safe Assembly

The Technetics Group QDS is engineered to simplify flange assembly and disassembly while requiring significantly less space than traditional bolted systems.

Its quick-install design is especially valuable in radioactive or hazardous environments, where minimizing personnel exposure is essential and remote handling capabilities are critical.

Key Features of the Quick Disconnect System (QDS)

Engineered for performance, safety, and ease of use, the Technetics Group Quick Disconnect System (QDS) offers a range of advanced features that make it ideal for high-stakes environments, such as nuclear, aerospace and critical industrial applications:

- Rapid Assembly

Enables quick and secure tightening, reducing installation time and improving operational efficiency. - Compact, Space-Saving Design

Requires significantly less space than traditional bolted flange systems — ideal for confined or complex assemblies. - Tool-Free or Remote-Handling Capability

Designed for easy assembly and disassembly, including remote operation in hazardous or radioactive environments. - Flexible Design Options

Available in both standard configurations and custom-engineered solutions to meet specific application requirements. - Extended Service Life

Built for durability, with a proven operational lifespan of over 10 years in demanding conditions. - Validated by Finite Element Analysis (FEA)

Each assembly is fully validated using FEA, ensuring structural integrity, as well as compliance to calculation codes or standards (RCCM, RCCM-RX, CODAP and others on demand) and performance under specific customer working conditions. - Optional Non-Magnetic Construction

Suitable for sensitive environments where magnetic interference is not tolerated or must be minimized. - No Twisting Torque on Piping

Protects pipe integrity by eliminating torsional stress during installation or operation.

Industries and Applications – Serving the World’s Most Demanding Sectors:

- Nuclear Energy

Used in primary loops, filters, thermocouple nozzles and numerous flanges for cavity filling and maintenance operations. - Ultra-High Vacuum (UHV) Systems

Ideal for particle accelerators, fusion research and other vacuum-critical applications. - Semiconductor & Thin Film Processing

Compatible with PVD, CVD and etching equipment for cleanroom and high-purity environments. - Cryogenics

Reliable sealing at extremely low temperatures, suitable for superconducting and liquefied gas systems. - Aerospace & Defense

Designed for space-constrained, high-performance systems where weight, reliability and thermal resistance are critical, such as engine test rigs for space shuttles. - Gas & Chemical Delivery Systems

Ensures safe, leak-tight performance in corrosive and high-pressure chemical transport. - National Laboratories & Research Facilities

Trusted by leading institutions for mission-critical experiments and prototype systems.

Properties and Technical Information – Engineered for Extreme Conditions

Technetics Group sealing systems are built to perform in the most demanding environments, offering exceptional resistance to pressure, temperature and dimensional challenges.

Performance Highlights:

- Extreme Temperature & Pressure Capability

Designed for applications ranging from ultra-high vacuum (UHV) conditions to high-pressure systems up to 500 bar (7.252 PSI). - Wide Operating Temperature Range

Reliable sealing from -321°F to 1,112°F (-196°C to 600°C), making it suitable for cryogenic to high-temperature applications. - Broad Dimensional Compatibility

Supports pipe sizes from DN 10 to DN 600, accommodating a wide range of system requirements, with remote handling options.

Resources

QDS Brochure, Product Overview Brochure, Nuclear Brochure, Metal Seal Master Catalog,