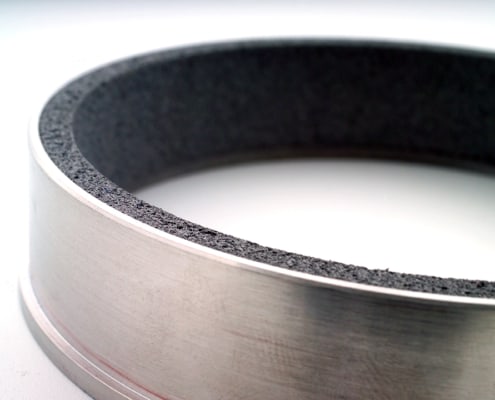

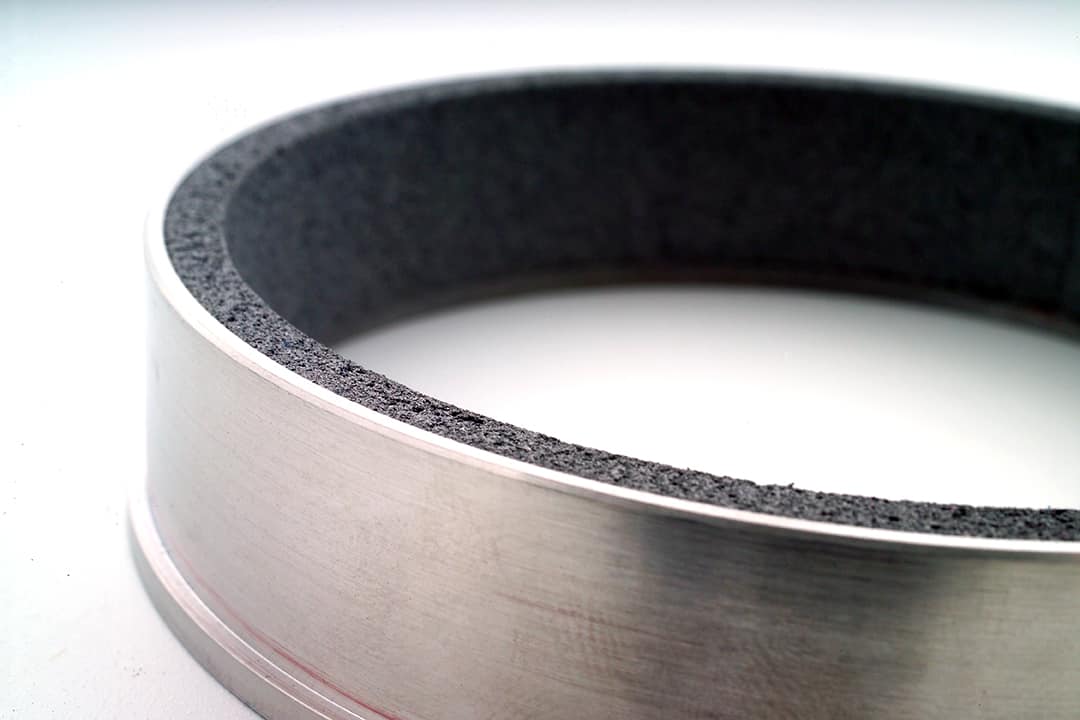

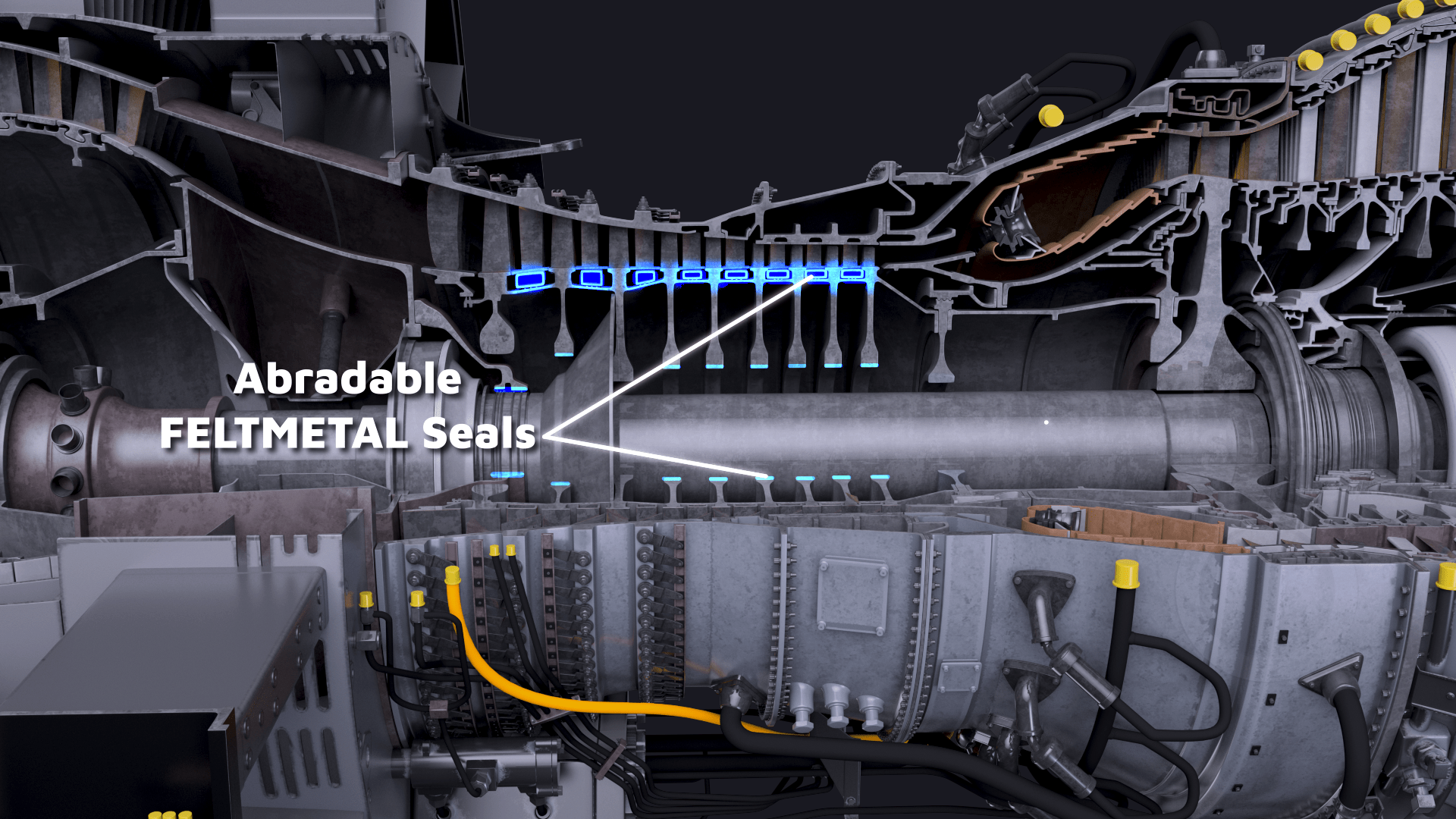

After 50 years and over 1 billion hours of successful operations, it is no wonder that FELTMETALTM Abradable Seals have been adopted by major gas turbine manufacturers for flow path efficiency improvements.

About Technetics Group Abradable Seals

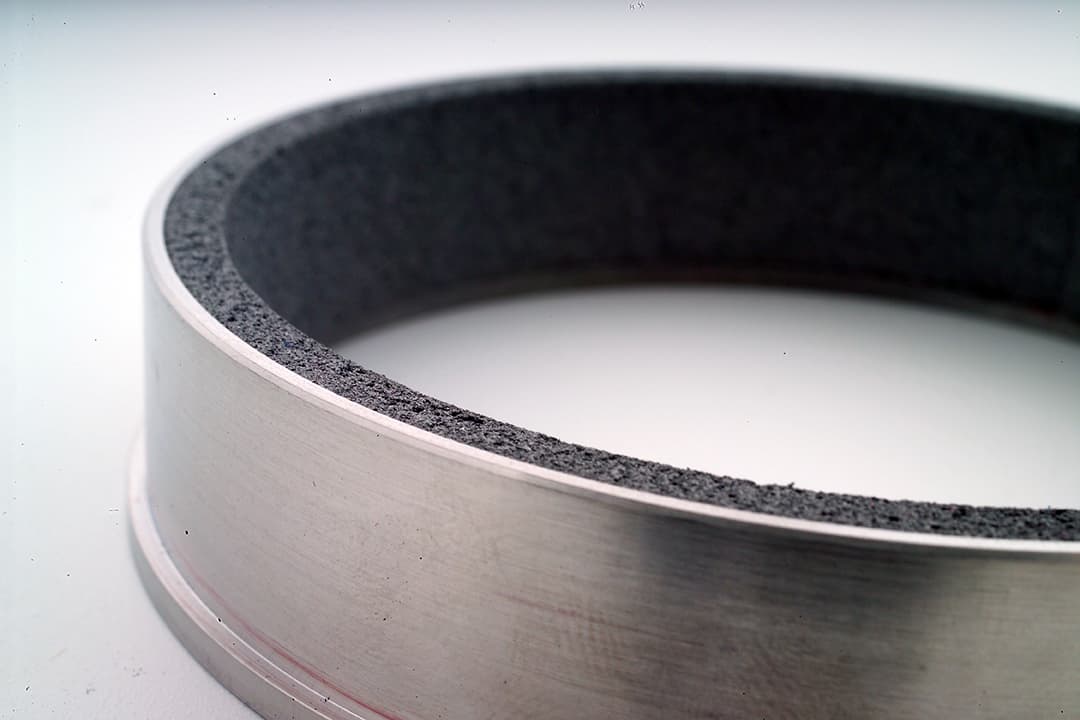

Abradable seals, when applied to stationary engine parts, allow for the complete sealing of blade tips and interstage labyrinth seal knife edges through the full 360º arc of rotation while minimizing or eliminating wear on the expensive rotating hardware. Also, by installing this rub-tolerant material, engine operating clearance can be minimized with attendant maximization of engine efficiency.

Product Features

- Built for extreme temperatures: Technetics Group FELTMETALTM Abradable Seal material provides superior clearance control in blade tip and labyrinth seal applications up to 1400˚F (760˚C)

- Wide variety of customization: Technetics Group FELTMETALTM Abradable Seal material can be manufactured to virtually any size or thickness, and can be rolled, formed, or machined to its final configuration

Industries and Applications

- Gas turbine manufacturers for flow path efficiency improvements

- Aerospace and industrial turbine applications, where our FELTMETAL™ Abradable Seals are used in blade outer seals, blade inner seals and labyrinth seals

Properties and Technical Information

- Fibers

Seals are made from Technetics Group’s metal fibers. Fiber choice is usually defined by the temperature requirements of the application. - Densities

Product densities generally range from 16% (of solid) to 32%. Density of a porous metal is 100 minus percent porosity. - Seal Segments

These materials have been furnished in segments which are generally .1 to .3″ thick. Length tolerances are + 1/16-0″ and width tolerances are ± .020″. Thickness tolerances are ± 7% of nominal.