Critical Sealing Solutions for Commercial Aircraft

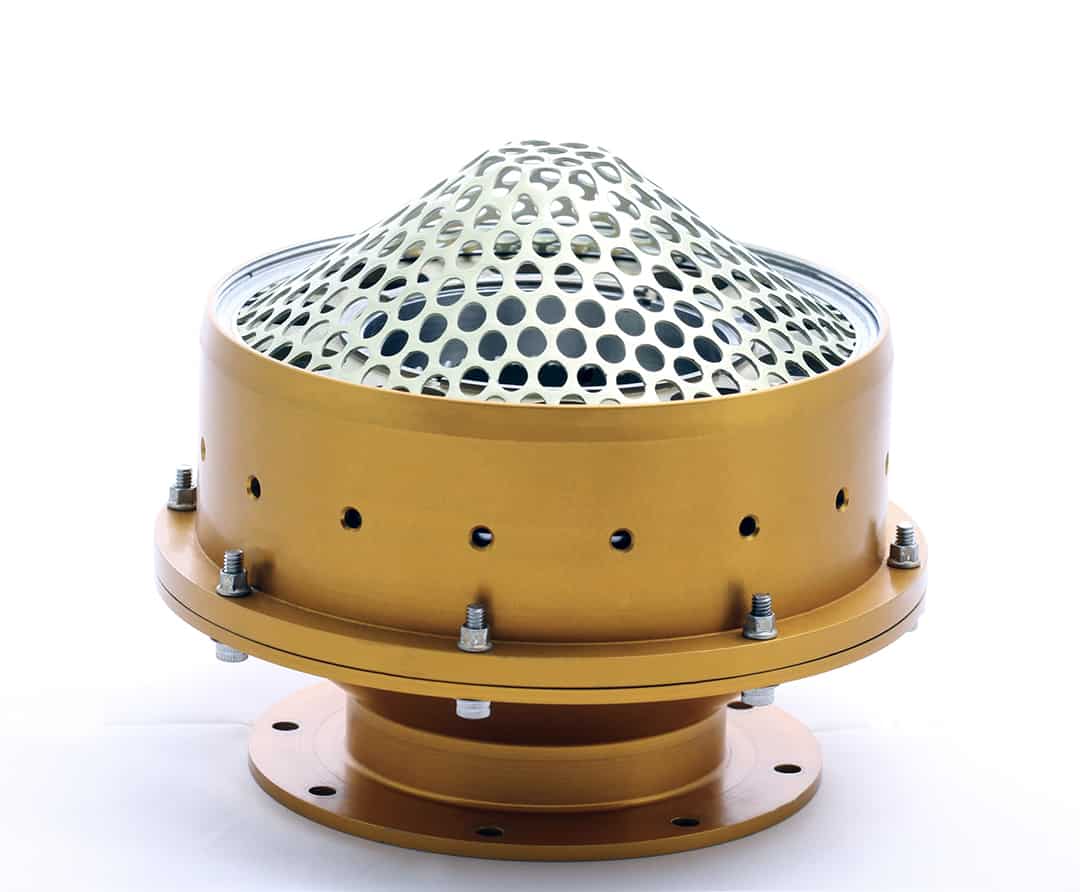

When an aircraft soars 30,000 feet in the sky, Technetics Group keeps your confidence high. Our critical components are found throughout nearly every section of a commercial airliner, from the APU exhaust to the gearboxes to accessories to turbine engines. Technetics Group provides critical solutions to assist in pressure regulation, noise control, fluid conveyance and fire protection.

As aircraft design grows increasingly complex, so does your reliance on better and longer lasting aircraft seals and engineered components. At Technetics Group, we meet the most stringent requirements for large and small commercial aircraft, regional and business jets, helicopters and unmanned aerial vehicles.

The importance of robust sealing solutions in aviation cannot be overstated. As aircraft operate under a myriad of conditions—from extreme altitudes to rapid temperature variations—the integrity of seals becomes pivotal in ensuring safety, efficiency, and performance. Technetics Group excels in developing advanced aircraft seals that meet the rigorous demands of modern aviation.

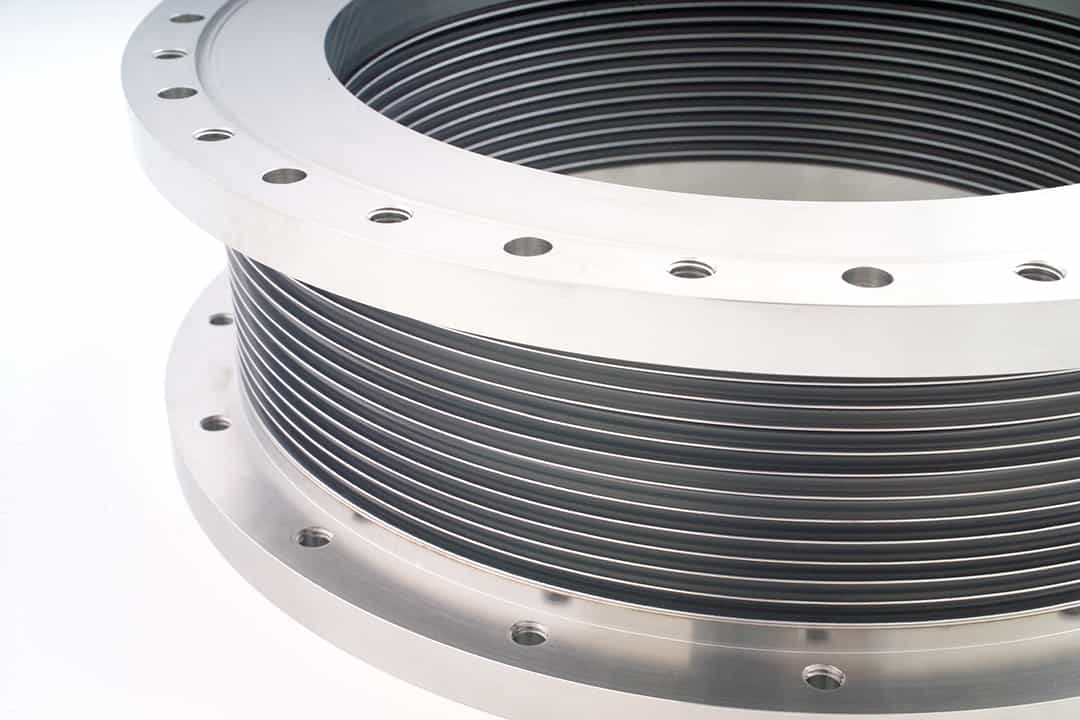

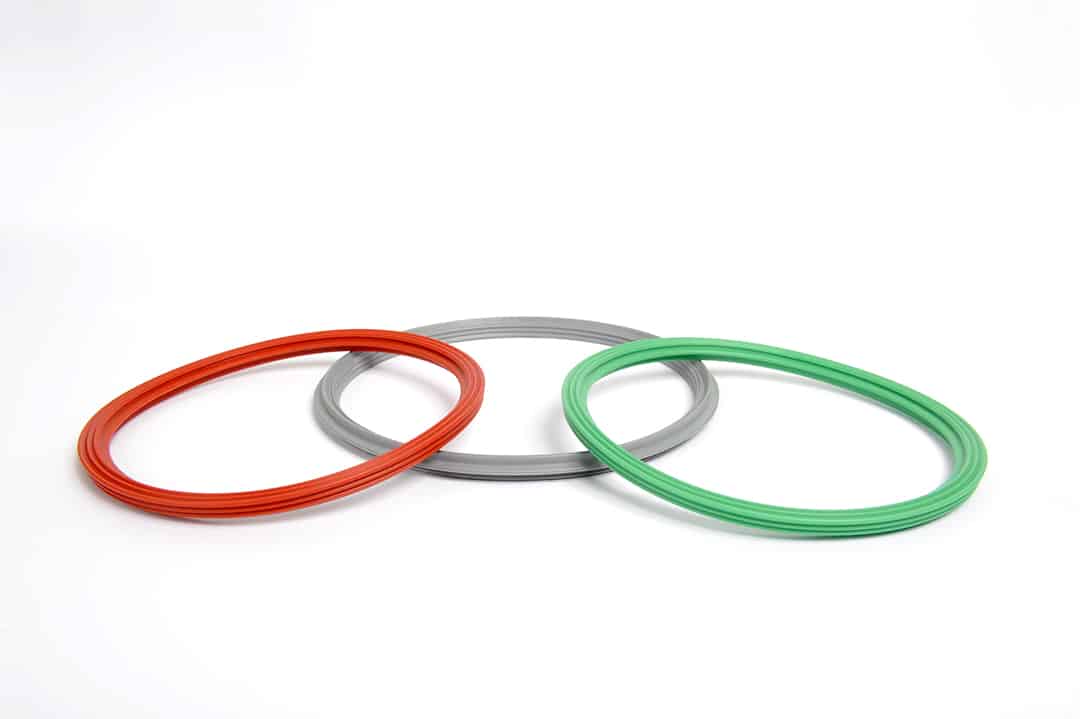

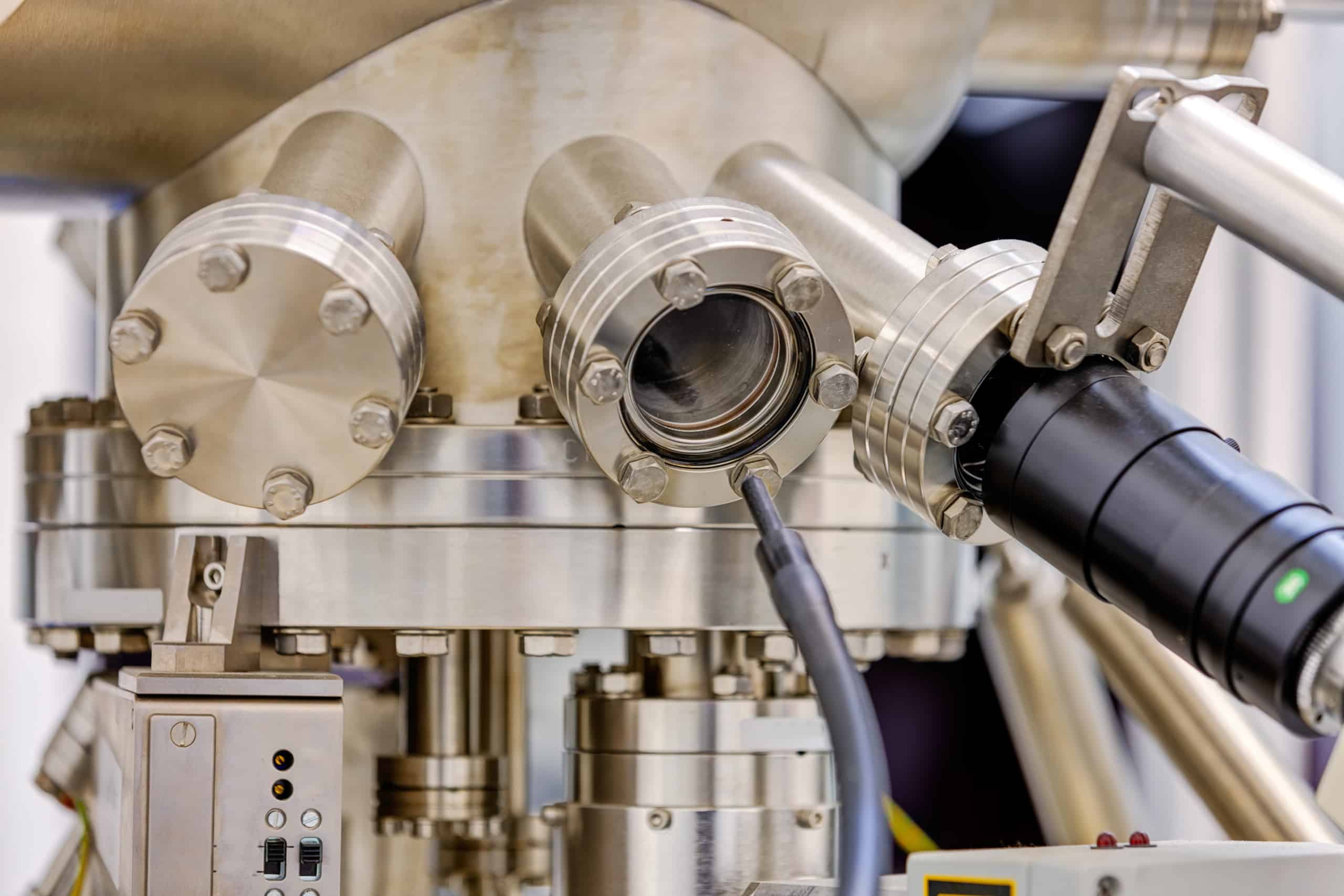

One of the core areas of focus is the development of aircraft engine seals. These seals are essential for maintaining optimal performance and longevity of the engine system. Our aviation seals contribute significantly to engine efficiency and operational safety by preventing leaks and controlling fluid dynamics. With our technological advancements, we create seals capable of withstanding the high pressures and temperatures encountered during flight.

One of the core areas of focus is the development of aircraft engine seals. These seals are essential for maintaining optimal performance and longevity of the engine system. Our aviation seals contribute significantly to engine efficiency and operational safety by preventing leaks and controlling fluid dynamics. With our technological advancements, we create seals capable of withstanding the high pressures and temperatures encountered during flight.

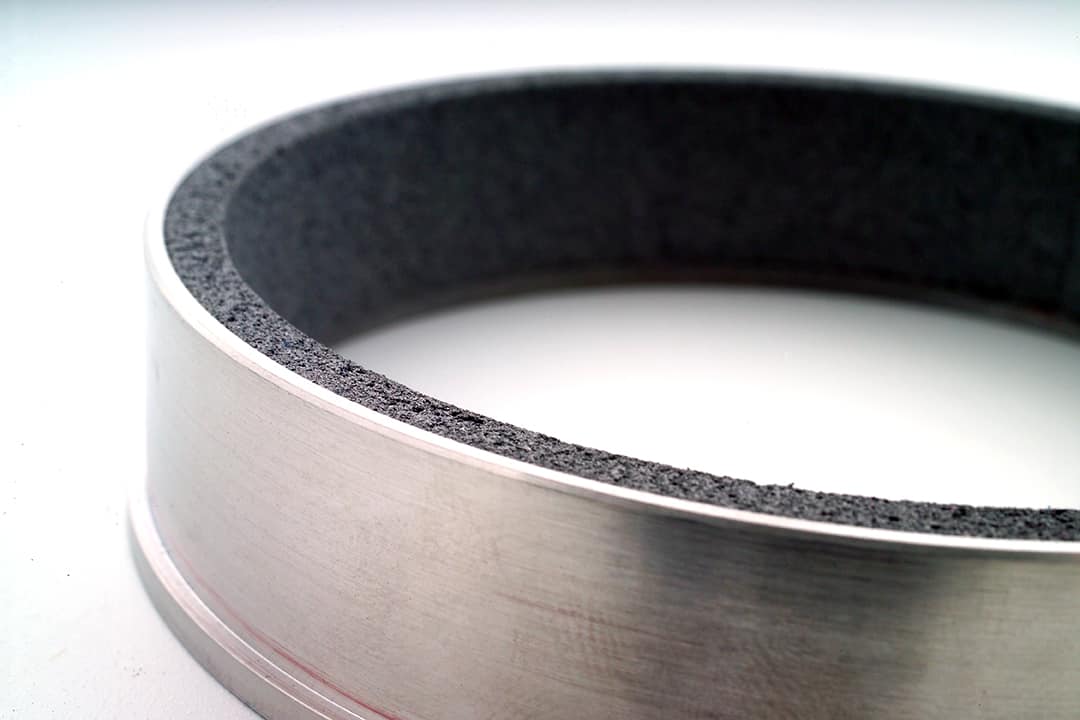

Among our innovative products are our abradable seals, typically found in the high-pressure compressor section of turbine engines. These seals provide a precise fit, enabling improved clearance control, which enhances the gas path flow through the turbine and increases efficiency. This also minimizes wear, which is particularly crucial in turbomachinery applications, where optimal performance is demanded to enhance fuel efficiency and reduce emissions. Our abradable seals are engineered to reduce clearance, thereby improving overall engine performance.

Helicopter seals represent another critical component of our sealing solutions. With the unique challenges posed by rotary-wing platforms, including variable loads and environmental exposure, our helicopter seal designs ensure reliability and durability. These seals are paramount for dynamic assemblies, effectively managing oil leaks and enhancing gearbox performance.

Helicopter seals represent another critical component of our sealing solutions. With the unique challenges posed by rotary-wing platforms, including variable loads and environmental exposure, our helicopter seal designs ensure reliability and durability. These seals are paramount for dynamic assemblies, effectively managing oil leaks and enhancing gearbox performance.

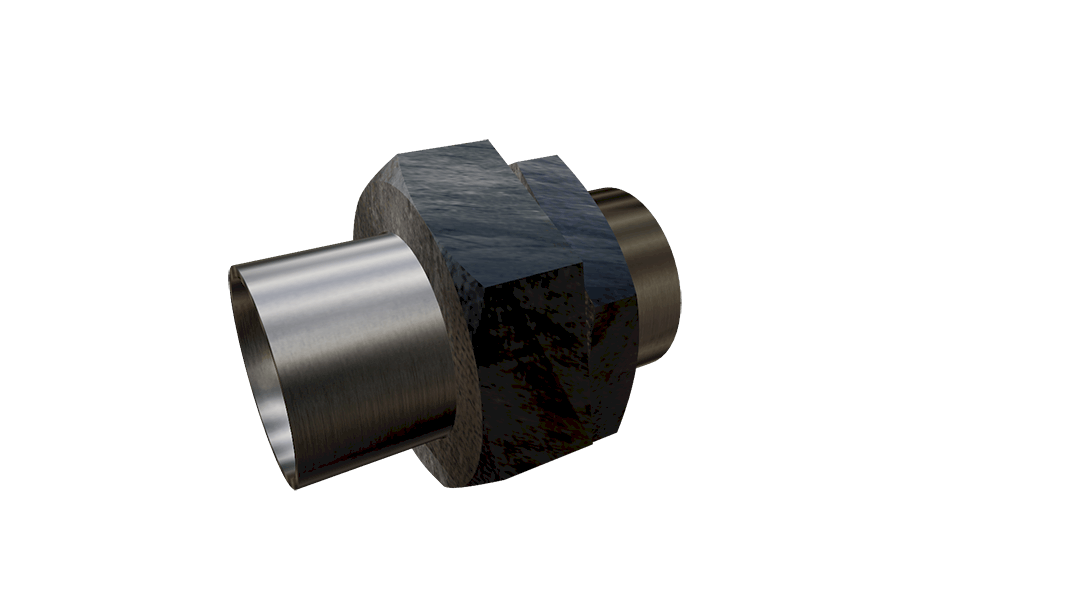

The mainshaft seal is a vital component in both fixed-wing and rotary-wing aircraft. This seal is designed to protect the mainshaft assembly from contaminants while preventing critical fluid loss. Proper sealing in this area is essential to maintain the operational integrity of the aircraft, especially as aircraft systems continue to become more sophisticated with increased performance demands.

Another significant advancement in sealing technology is the carbon face seal, which provides a virtually leak-proof interface under extreme conditions. This type of seal utilizes carbon material, which maintains structural integrity and performance even in high-temperature applications. Additionally, the design of carbon face seals ensures good vibration performance, making them suitable for environments where mechanical resonance is a concern. These seals also accommodate significant shaft movement, empowering them to maintain efficacy in rotating machinery applications where reduced friction and wear are crucial, thereby extending the lifespan of vital components.

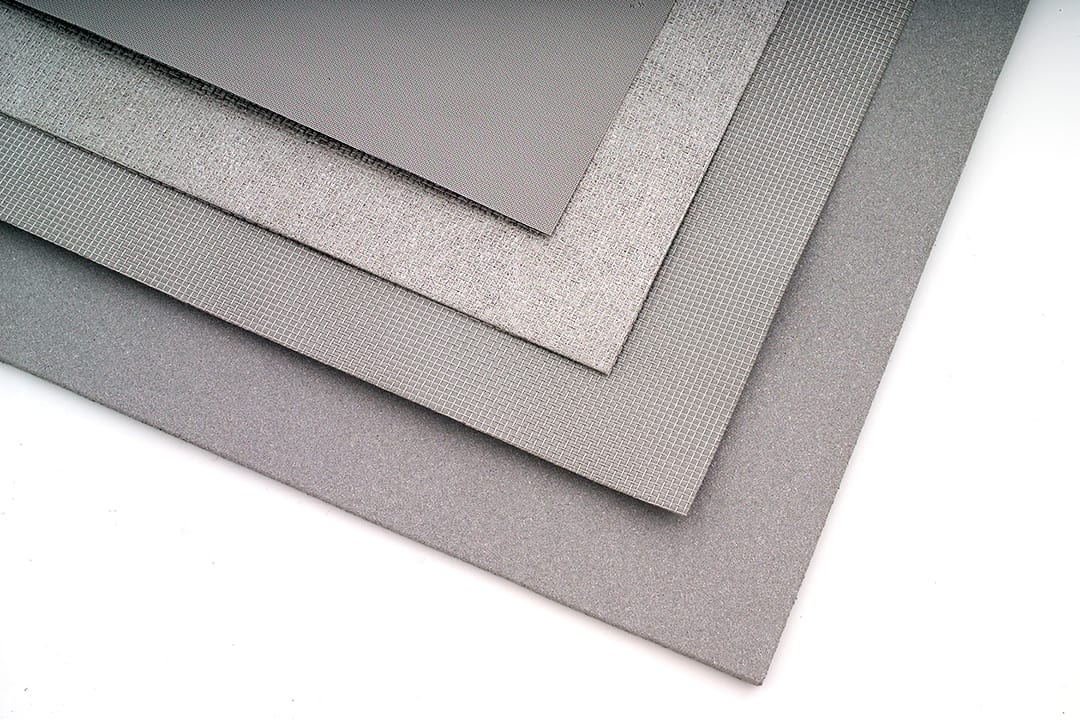

In the aviation sector, addressing acoustic noise pollution is paramount for enhancing passenger comfort and meeting stringent regulatory standards. Technetics Group’s FELTMETAL™ acoustic media stands at the forefront of acoustic abatement technology, delivering exceptional sound-dampening properties without compromising structural integrity. By employing advanced materials that effectively absorb sound waves, FELTMETAL™ contributes to the industry’s initiatives aimed at improving environmental impact and passenger satisfaction. As aircraft manufacturers increasingly prioritize acoustic performance in their designs, our commitment to providing innovative materials ensures compliance with evolving noise regulations while enhancing modern air travel’s overall efficiency and comfort.

Lastly, the general category of aircraft seals encapsulates our extensive range of products designed to address the specific needs of various aircraft models and configurations. Whether it’s for commercial airliners or specialized business jets, Technetics Group is committed to delivering bespoke sealing solutions that adhere to the highest industry standards, ensuring that every aircraft we support is built for exceptional performance and reliability.

Lastly, the general category of aircraft seals encapsulates our extensive range of products designed to address the specific needs of various aircraft models and configurations. Whether it’s for commercial airliners or specialized business jets, Technetics Group is committed to delivering bespoke sealing solutions that adhere to the highest industry standards, ensuring that every aircraft we support is built for exceptional performance and reliability.

Our comprehensive approach to critical sealing solutions in aviation underscores our commitment to innovation and excellence. By integrating advanced materials and cutting-edge engineering practices, Technetics Group continues to lead the way in providing exceptional aircraft seals that enhance safety and efficiency in the skies.