At Technetics Group, even though we established our manufacturing process over 25 years ago we are continuously looking for ways to improve our processes and ship quality parts to our customers with shorter lead-times. Our proprietary techniques allow us to manufacture a wide range of brush seal designs to meet your unique requirements.

About Technetics Group Brush Seals

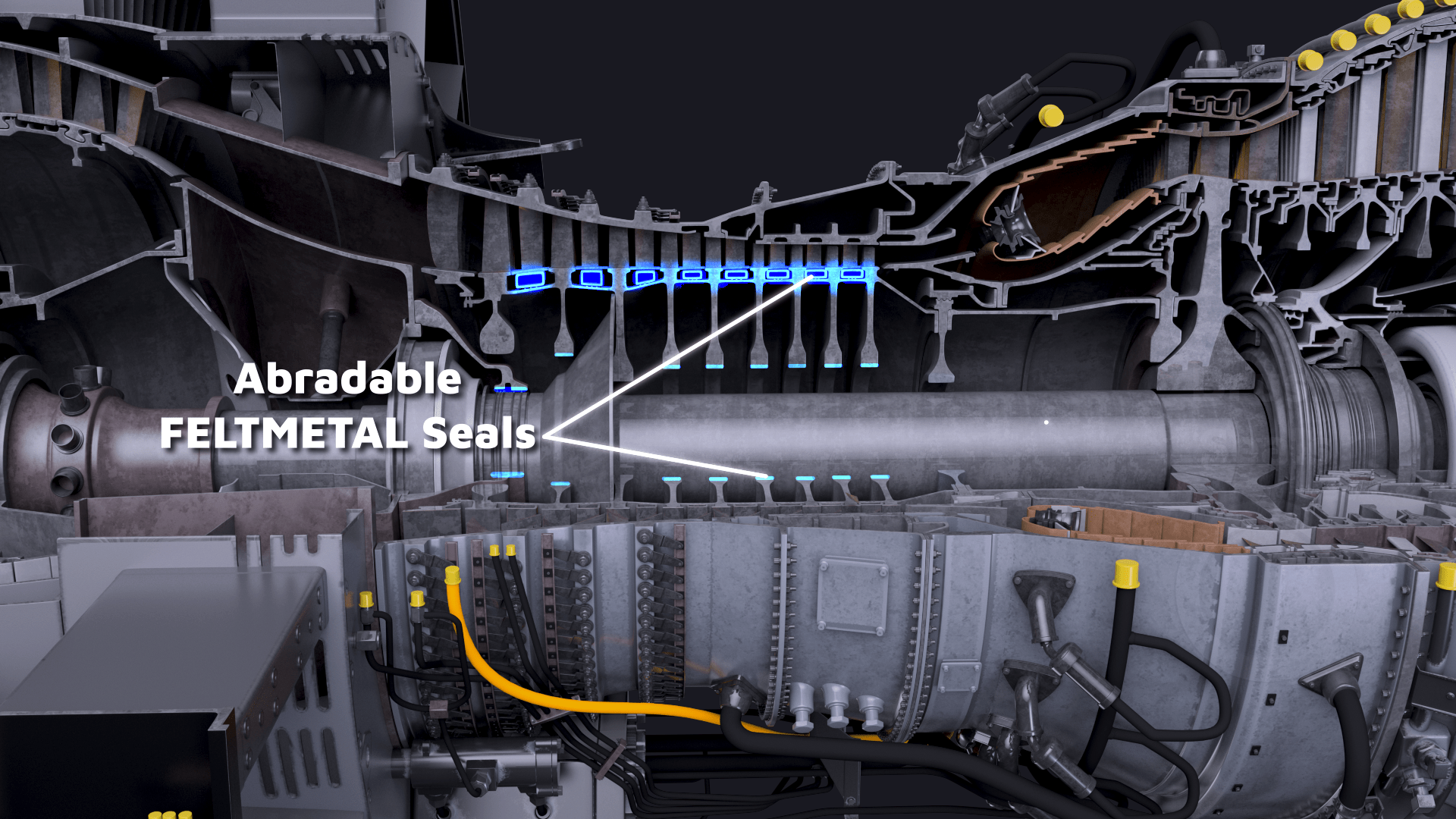

Brush seals work by absorbing radial deflections from the rotor during transient operations. The seal then follows the rotor back to the steady state operating position to maintain minimum leakage. Each metal seal’s brush pack is composed of thousands of finely packed wire bristles. The bristle material, a cobalt/nickel alloy, is chosen to provide an optimal combination of wear properties and oxidation resistance. The back plates and side plates are typically fabricated from stainless steel or nickel alloys and are chosen based on the case material to account for thermal expansion.

About HELIOCARB® Carbon Brush Seals

Using a patented manufacturing and assembly process, we’ve developed an ideal rotating sealing solution for your most critical industrial applications. A circular seal that’s easy to install, our HELICOCARB® carbon brush seals use a network of soft, compressed carbon bristles inside the housing to deliver lower leak rates, lower friction, higher speeds and a longer product lifespan.

Brush Seal Product Features and Benefits

- Reduced wear rate means longer life

- Consistent flow provides predictable performance

- Higher-pressure operation yields flexibility in design

- Reduced heat generation ensures a cooler rotor

- More than 5 times less leakage than labyrinth seals; carbon brush seals provide 90% less leakage

- Pressure balanced design reduces force and prevents bristle pack “hang up” following a radial excursion

- Repairable and insert-only options are available

Industries and Applications

- Gas turbine engines

- Steam turbine engines

- For use in:

- Main shafts

- Gearbox

- Compressors

- APUs

- Bearing seals

- Centrifugal pumps

- Industrial air fan

Properties and Technical Information

- Technical Characteristics

- Pressure: Up to 300 psid [20 Bars]

- Temperature: Up to 1250°F [677°C]

- Surface Speed: Up to 1200 ft/s [366 m/s]

- Customizable Options

Single brush seals and multiple brush seals in series can be produced with bristles on the outside diameter, inside diameter, and axially both for rotational and axial movement. Rings are available as a solid ring, segmented or linear.- Cross-sections

Technetics Group has manufactured various brush seals with “non-traditional” cross-sections to help customers find the best fit for their system. We can manufacture cross-sections as thin as .125″ [3.1 mm]. - Sizes

We can produce diameters ranging from .75″ inches to over 200″ inches. - Fiber Diameter

Our primary sizes are 2.8 mil, 4 mil, and 5.6 mil wire but we can work with larger size wire as well. - Brush Angle

Our primary range is 30° to 60° but we can accommodate other angles if necessary. - Packing Density

Our typical range is 2,500-5,000 wires per inch but can accommodate other densities as needed. Bi-directional bristles are also available.

- Cross-sections

- Wire Alloys

Our primary wire material is Haynes® 25 but we can work with a wide variety of additional alloys including Hastelloy® X, Hastelloy® C-276, lnconel® 600 and stainless steel.