When critical technologies demand advanced material science and application expertise, Technetics delivers innovative, reliable, and high-performance elastomer solutions that meet — and often exceed — the expectations of OEMs in specialized industries.

Our molded, extruded, and inflatable seals play a vital role in helping OEMs overcome complex sealing challenges. Backed by a dedicated engineering and design team utilizing cutting-edge techniques, such as finite element analysis (FEA), and leveraging best-in-class elastomer processing capabilities, Technetics ensures superior performance across a wide range of demanding applications.

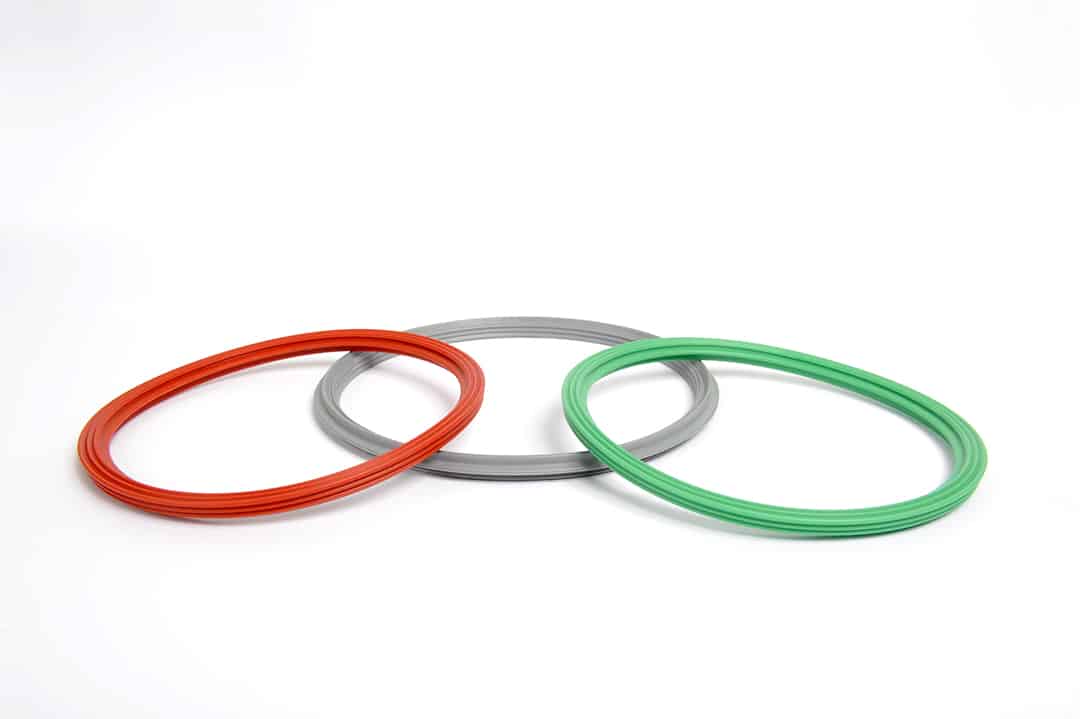

Technetics Group Elastomer & CEFIL’AIR® Inflatable Seals solutions

At Technetics Group, our elastomer solutions — including molded, extruded, and inflatable seals — are engineered for applications where precision sealing and dedicated handling are critical. Whether you’re aiming to prevent internal or external contamination or seeking to optimize complex assemblies, such as door systems, our deep engineering expertise and advanced material science turn your ideas into reality — whether during R&D or in solving challenges with existing designs.

Our strength lies in material innovation. We select or custom-develop the ideal rubber and additive combinations to meet the exact requirements of your application. To ensure your success, we offer a comprehensive suite of services, including:

- Custom formulation and material selection (Low volatile Silicone available)

- In-house and MAESTRAL laboratory testing and characterization

- Full quality assurance and traceability

- Collaborative co-development based on decades of industry experience

From concept to production, Technetics is your trusted partner for high-performance elastomer sealing solutions.

Product Features

- Highly Flexible Designs

Available in a wide range of shapes and sizes or fully customized to meet the most stringent application needs. - Cost-Effective Development

Optimized non-recurring engineering (NRE) and tooling costs with in-house design and manufacturing capabilities, ensuring faster lead times. - Simplified Installation

Engineered for easy groove fitting and seamless integration into your assemblies. - Quick Connect/Disconnect

CEFIL’AIR® inflatable seals offer effortless connection and disconnection, ideal for applications requiring frequent access or maintenance. - Enhanced Performance

Improved chemical and temperature resistance and mechanical properties for demanding environments. - Durability in Motion

Wear-resistant materials designed for abrasive, dynamic, or semi-dynamic applications. - Antimicrobial Protection

BIO-GUARDIAN® elastomers inhibit bacterial growth and biofilm formation, supporting hygiene-critical applications. - Precision Handling

Perfect for moving, holding, lifting, or clamping large, delicate, or complex components with care and control.

Industries and Applications

- Aerospace

- Phonic isolation systems for engine-test-facility doors

- Aircraft access doors and cockpit canopies

- Leak-tight panels for pressurized environments

- Defense

- Leak-tight panels for mission-critical enclosures

- Nuclear

- Movable cofferdam bulkheads for containment

- Sealing solutions for storage and transport containers

- Material and personnel airlocks in nuclear power plants

- Pharmaceutical & Life Sciences

- Isothermal chambers for controlled environments

- Cleanroom sealing solutions

- Sliding or quick-locking doors for autoclaves, sterilizers, dryers, and reactors

- Centrifugal filters (e.g., access doors and drainage hoppers)

- Industrial Applications

- Cofferdams for temporary sealing and isolation

- Pneumatic conveying systems (e.g., bagging hoppers, valve gates)

- Sliding or quick-locking doors for autoclaves and ovens

- Centrifugal filters (e.g., access doors and drainage hoppers)

- Oil & Gas

- Floating production storage and offloading (FPSO) systems: sealing between a buoy and a vessel

Properties and Technical Information

- Large Material Selection

- Choose from silicone, SBR, EPDM, CR, NBR, HNBR, FKM, and more materials, many of which offer highly resistant mechanical and physical properties to ensure a long lifetime and numerous operating cycles.

- Extreme Temperature and Pressure Performance

- Pressure range: from vacuum to several tens of bars

- CEFIL’AIR® seals temperature range: from -58°F to 392°F (-50°C to 200°C)

- Molded seals temperature: from -166°F to 572°F (-110°C to 300°C)