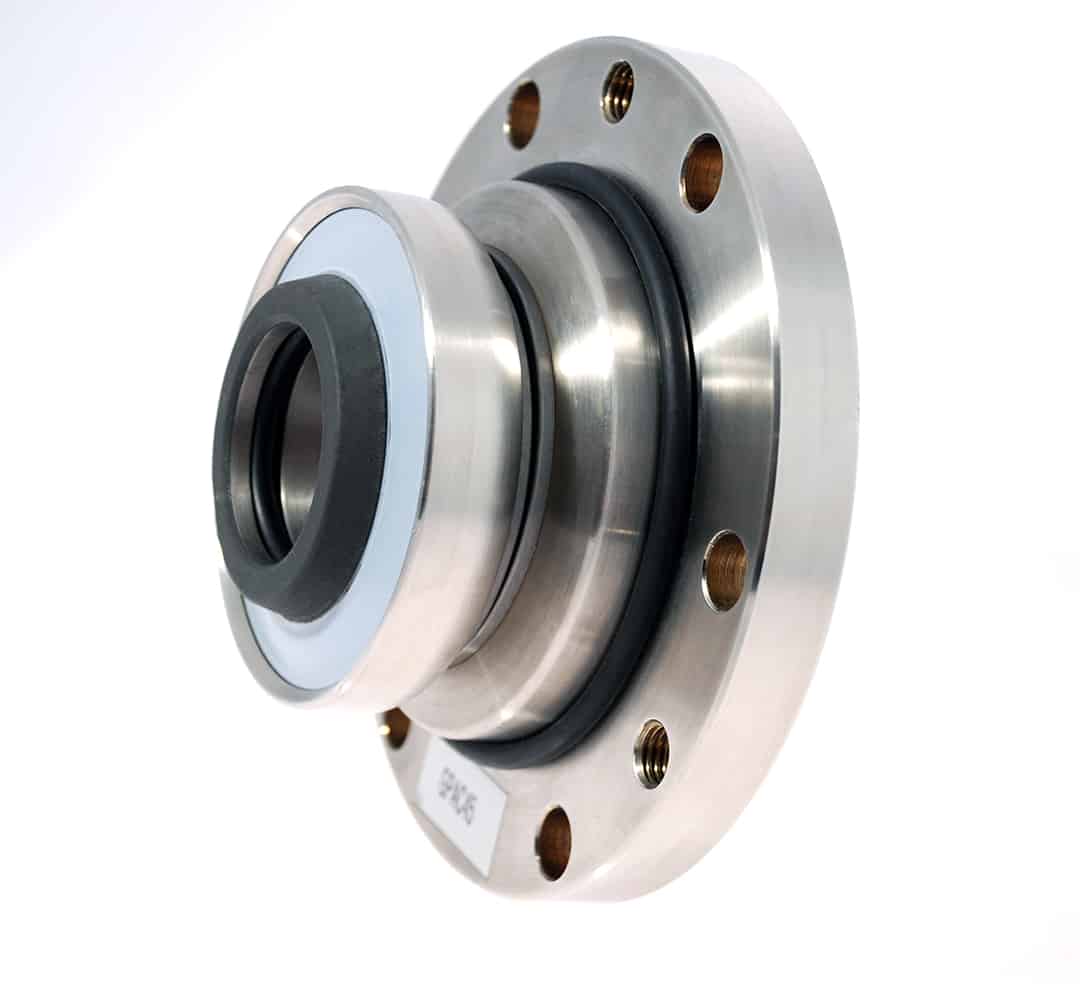

Since 1967, Technetics Group has designed and produced a wide range of mechanical seals, engineered for the most demanding and varied rotary shaft applications.

With trusted brands such as QUALISEAL®, GULLIVER® and CEFILAC GPA®, we deliver extended life and low leakage while accommodating a wide range of sizes, speeds, pressures and temperatures in both dry and wetted applications.

What is a Mechanical Seal, and What Goes Into the Design?

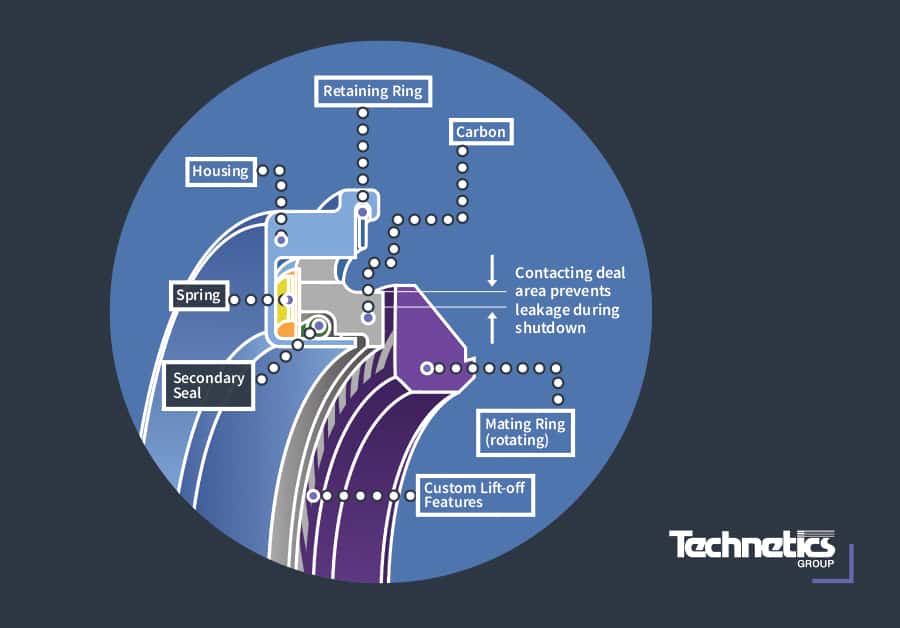

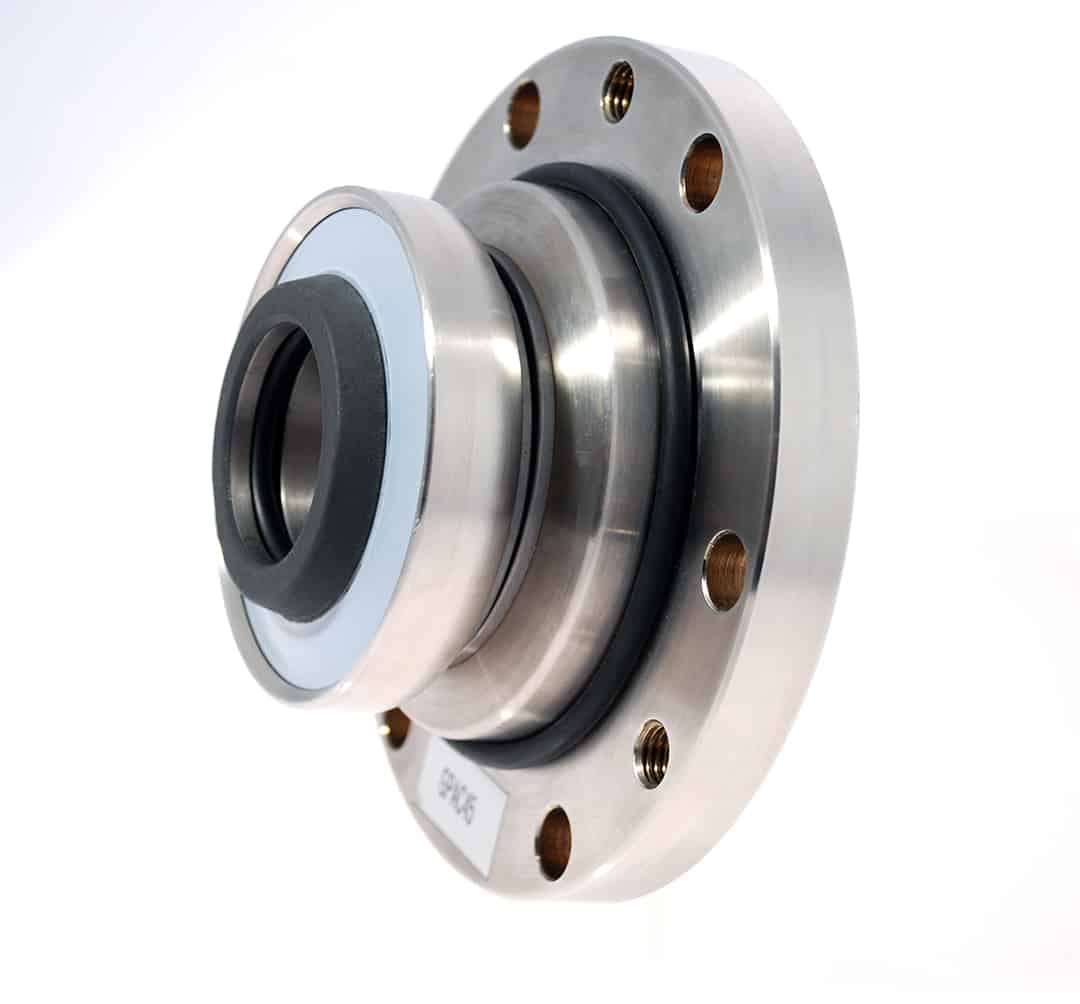

The primary purpose of a mechanical seal is to separate air from fluids in rotating applications. Mechanical seals consist of a rotating component, a rotor or mating ring, and a stationary component often called the seal. Qualiseal® mechanical seal applications typically demand reduced leakage and seal longevity.

The core design consideration is a function of the system pressure and the surface velocity of the rotating component. Our engineers consider the limited physical space constraints, or envelope, the seal must be able to fit into. We review our customer’s main concerns, whether the leak rate or the seal’s life. When choosing the materials for the seal construction, the media the seal will be exposed to is an issue of utmost concern to the seal’s design.

The Top 4 Reasons Mechanical Seals Fail

Mechanical seals can fail due to

- incorrect analysis techniques

- ineffective designs

- not designing for the environment

- inefficient manufacturing processes.

In aerospace applications, this can lead to failed qualifications, latent failures in the field, reduced system life and even catastrophic failures at either component or system level.

Typical Applications for Mechanical Seals

0:10 – Spring-energized contacting face seals

1:17 – Bellows energized contacting face seals

1:28 – Circumferential Seals

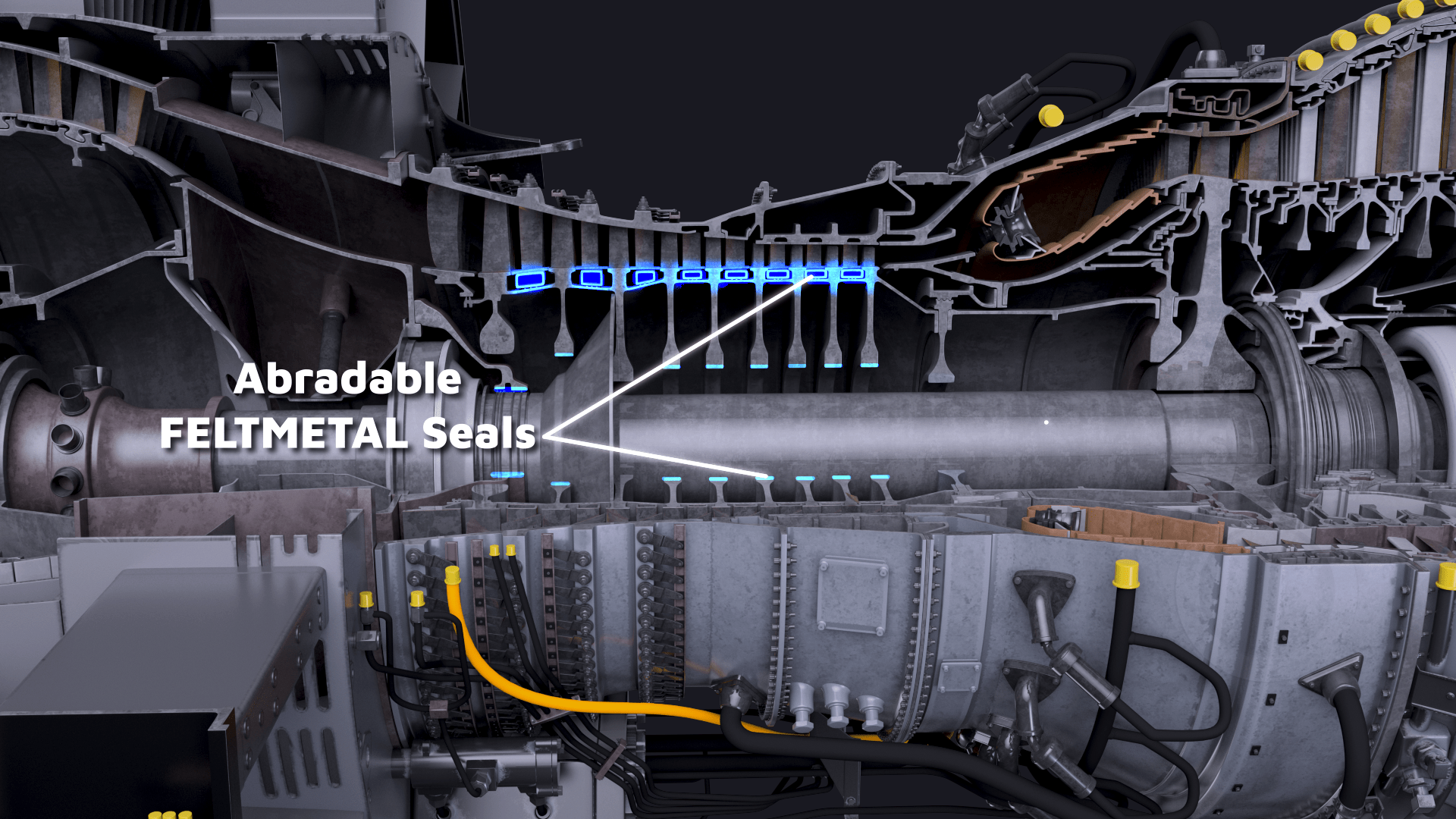

We typically deal with three types of mechanical seals in critical aerospace and industrial applications: contacting face seals, non-contacting face seals and bellows-energized contacting seals. Technetics Qualiseal® mechanical seals are custom engineered to meet the demanding requirements in these situations.

Spring-energized contacting face seals are used in low-pressure, low-speed applications. In aerospace applications, these mechanical seals would typically be used for oil pumps, scavenge pumps, fuel transfer systems, and gearboxes. They are in mixers and other slower rotating applications in the industrial environment. In higher speed applications, they are in gearboxes, starters, and accessory starters on engines. Hydraulics, fuel pumps, industrial compressors or screw compressors require mechanical seals that can withstand higher pressures.

Small engine main shaft applications may need bellows-energized contacting seals.

Aerospace and industrial main-shaft applications, like compressors, may need circumferential seals.

Essentially, Technetics can put a seal anywhere there’s a bearing.

Types of Mechanical Seals

Technetics specializes in various mechanical seals, including contacting and non-contacting face seals. They both operate as a sealing system with a stationary component coupled with a matched axial rotating part. Low-speed applications will typically use contacting face seals.

Non-contacting, or lift-off, seals have unique grooves engineered into the seal rotor that create a pumping action that causes the rotor and seal nose to separate. This separation generates less friction and heat than contacting face seals and provides almost no leakage and a longer life for the seal.

Circumferential seals operate radially instead of axially between the shaft and seal. There are two types of circumferential seals: controlled gap and fractured-ring seals. The controlled-gap seal allows for tighter tolerances/clearances and more controlled leakages because all the surrounding components grow at the same rate as they heat up. Fractured-ring seals are typically used in space and turbo-pump applications, sealing radially with a fragmented carbon component. This fragmentation allows the material and the seal to expand with the shaft as it heats and cools, maintaining constant contact.

Mechanical Seal Analysis and Testing

Technetics is proud to be able to deliver Qualiseal® mechanical seals that work the first time, every time. Our customers have confidence in our solution proposals due to our comprehensive analysis tools and processes. This leads to a more efficient, streamlined design process which minimizes schedule risks for our customers. Technetics’ proprietary software and testing capabilities provide a solid foundation in predictive performance and quality reassurance.

In terms of testing capabilities, Technetics utilizes an in-house lab to validate seal designs with an astonishing set of five different test rigs. The mechanical seal testing equipment can simulate application environments, including on-engine conditions, high system pressures, various fluid tests, vibration, and high speeds. The process is vetted through FEA analysis and custom rig testing, providing our customers confidence in their sealing solution.

Hydrodynamic Mechanical Seals and Edge-welded Metal Bellows

Non-contacting Lift-Off Seal

- Negligible Wear Rate

- Low Operating Temperature

- Longer Seal Life

In critical use-cases, like aerospace, where a typical contacting seal is not an option, Technetics Qualiseal® hydrodynamic non-contacting lift-off face seals are a superior alternative. While other non-contacting seals fail due to the changes in altitude, Technetics’ Qualiseal® hydrodynamic lift-off seals maintain a consistently stiff air film throughout each operating condition. The unique geometric features designed into the rotor grooves create a pumping action to maintain separation from the seal. We manufacture and test each sealing system in-house.

Technetics also offers a mechanical seal incorporating edge-welded metal bellows that provide superior stroke capabilities and precise spring rates. This design ensures that the force balance equation stays consistent as the seal ascends altitude and runs through various operating conditions. Technetics optimizes our mechanical seals’ engineering design and manufacturing for even the most critical customer applications.

Frequently Asked Questions (FAQs) About Mechanical Seals

The material mechanical seals are made from dictates their temperature limits. Carbon is good up to 800 degrees Fahrenheit, while secondary seals and typical contact face seals are limited to 300-500 degrees Fahrenheit.

When evaluating mechanical seal applications, we’re interested in the surface speed, not just the rotating speed. Surface speed is a key input when determining the system’s pressure velocity (PV). We work with applications of up to one million PV.

Technetics can customize the seal to accommodate shaft diameters from 3/8” to 10 inches. We also consider the space envelope (the amount of space available for the seal).

Every seal leaks. Our goal is to engineer the most appropriate solution to meet that leakage requirement. Face seals allow small amounts of leakage, while circumferential seals may have more. We consider these allowances in the design and the seal recommendation.

Materials used in the manufacture of mechanical seals are also highly customizable. We select materials based on the application requirements: carbon and ceramics for more lubricity, high-pressure alloys or stainless steels for housings, springs and bellows, and performance elastomers, or PTFE, for secondary seals.

0:15 – Temperature Limits

0:55 – Speed Capabilities

3:00 – Size Limits

4:05 – Leakage Rates

4:45 – Materials for Mechanical Seals