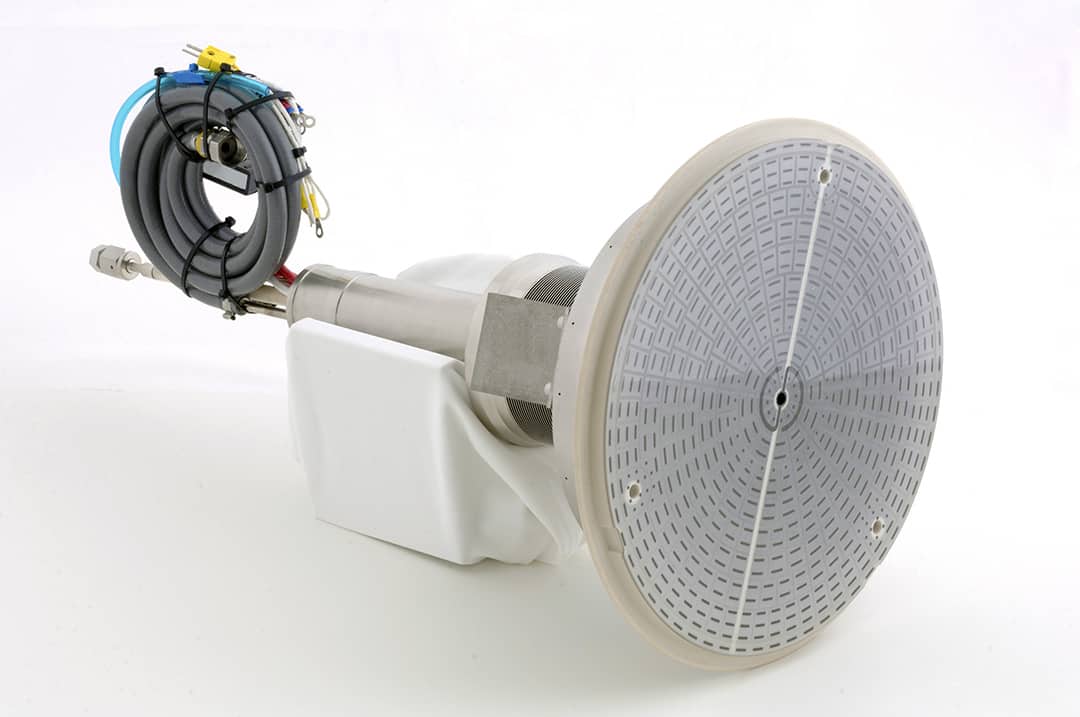

C-FLEX™ Metal Seal High-Performance C-Ring Seals

The sealing design of C-FLEX™ metal C-rings is based on the elastic deformation of a metal “C” substrate which, during the compression cycle, gives a contact point on each sealing surface. The substrate characteristics determine the compressive load of the seal. This load combined with an accurate compression rate results in a specific pressure which is directly related to the sealing level obtained. A certain specific pressure is necessary to make the seal flow into the flange imperfections. In service, the system pressure supplements this load. A softer surface treatment is available to increase the plasticity of the seal and reduce the specific pressure necessary to reach the desired sealing level.

View the features and benefits of C-FLEX™ below

Features & Benefits

Properties:

- Pressure energized

- Cross-section and wall thickness designed to control loading

- Available for internal, external and axial pressure

- Range of materials (Alloy X750, 718, Waspaloy and other exotic metals)

- Platings and coatings: silver, gold, PTFE (others available)

- Temperature range: from -273°C to 730°C (-460°F to 1350°F)

- Pressure range: from medium vacuum to 2,000 bar (29,008 PSI)

- Leak range: Approximately ≤ 25 cc/min @ 50 psig Nitrogen per inch of diameter to ≤ 1 x 10-4 std.cc/sec Air. The actual leak rate will depend on seal load, surface finish, and surface treatment.

Optional Features:

- Tribological wear-resistant coatings available

- Custom shapes and sizes available