-

EventsCritical Sealing For Hydrogen Production and Storage On-Demand...In this webinar, prepare to learn about the challenges and solutions for this exciting green energy source, hydrogen.

EventsCritical Sealing For Hydrogen Production and Storage On-Demand...In this webinar, prepare to learn about the challenges and solutions for this exciting green energy source, hydrogen. -

EventsHydrogen-The Hydrogen Future is NowHydrogen has the potential to become a leader in green, renewable energy sources. Join us as Technetics Group sealing experts...

EventsHydrogen-The Hydrogen Future is NowHydrogen has the potential to become a leader in green, renewable energy sources. Join us as Technetics Group sealing experts... -

ArticlesHydrogen: Push Towards the Generation of Green H2The desire to move to sustainable energy sources and reduce carbon emissions is growing exponentially. Low-cost renewable energy sources (e.g.,...

ArticlesHydrogen: Push Towards the Generation of Green H2The desire to move to sustainable energy sources and reduce carbon emissions is growing exponentially. Low-cost renewable energy sources (e.g.,... -

ArticlesHydrogen Production: The Challenges and Practical ApplicationsAs the world shifts its focus to decarbonization initiatives, research shows responsible leaders will pour more technology and infrastructure into...

ArticlesHydrogen Production: The Challenges and Practical ApplicationsAs the world shifts its focus to decarbonization initiatives, research shows responsible leaders will pour more technology and infrastructure into... -

PodcastsGetting Technetical: Hydrogen-Push Toward the Generation of Green...There have been advancements in the research and development of clean energy sources. Hydrogen has been identified as a potential...

PodcastsGetting Technetical: Hydrogen-Push Toward the Generation of Green...There have been advancements in the research and development of clean energy sources. Hydrogen has been identified as a potential... -

PodcastsGetting Technetical: Flying in Green SkiesAviation contributes to 2% of all CO2 emissions, when aviation adopts green technologies, efficiencies and cost reductions will follow. The...

PodcastsGetting Technetical: Flying in Green SkiesAviation contributes to 2% of all CO2 emissions, when aviation adopts green technologies, efficiencies and cost reductions will follow. The...

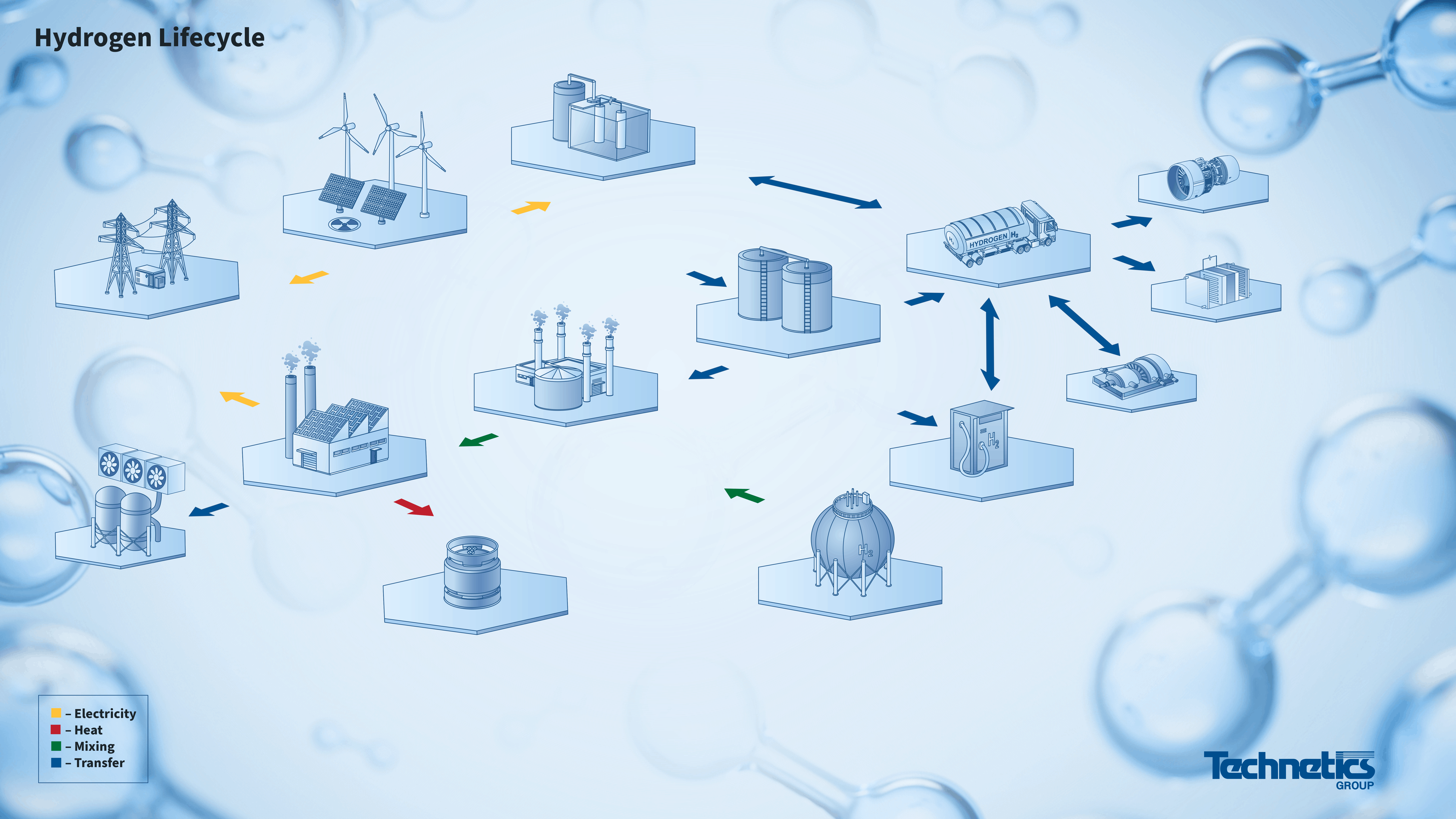

The Vital Role of Sealing in the Hydrogen Odyssey

Imagine a world powered by the most abundant element in the universe—hydrogen. This isn’t just a vision; it’s becoming a reality, and at the heart of this transformation is the hydrogen industry, burgeoning with potential yet fraught with challenges. As we navigate the complexities of hydrogen production and storage, one unsung hero emerges as critical to success: sealing technology. At Technetics Group, we understand that the journey to a hydrogen-powered future is paved with precision-engineered sealing solutions. These solutions are not just components but guardians of safety and efficiency, ensuring that every hydrogen molecule serves its purpose without compromise.

The Technetics Group Advantage in Sealing Solutions for the Hydrogen Industry

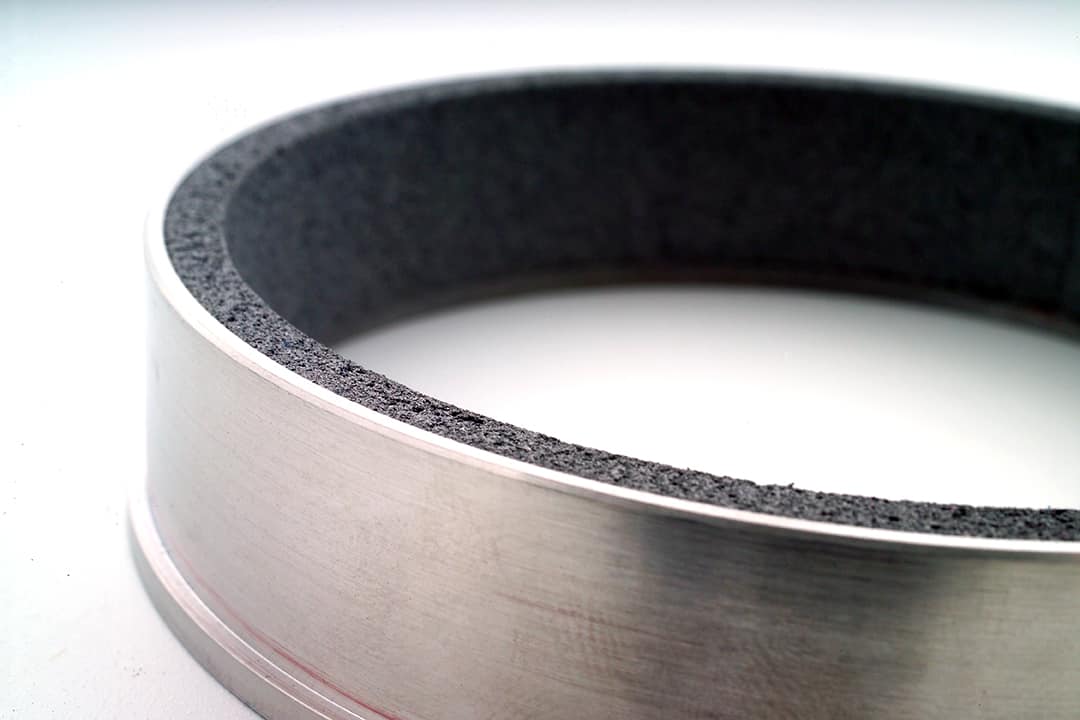

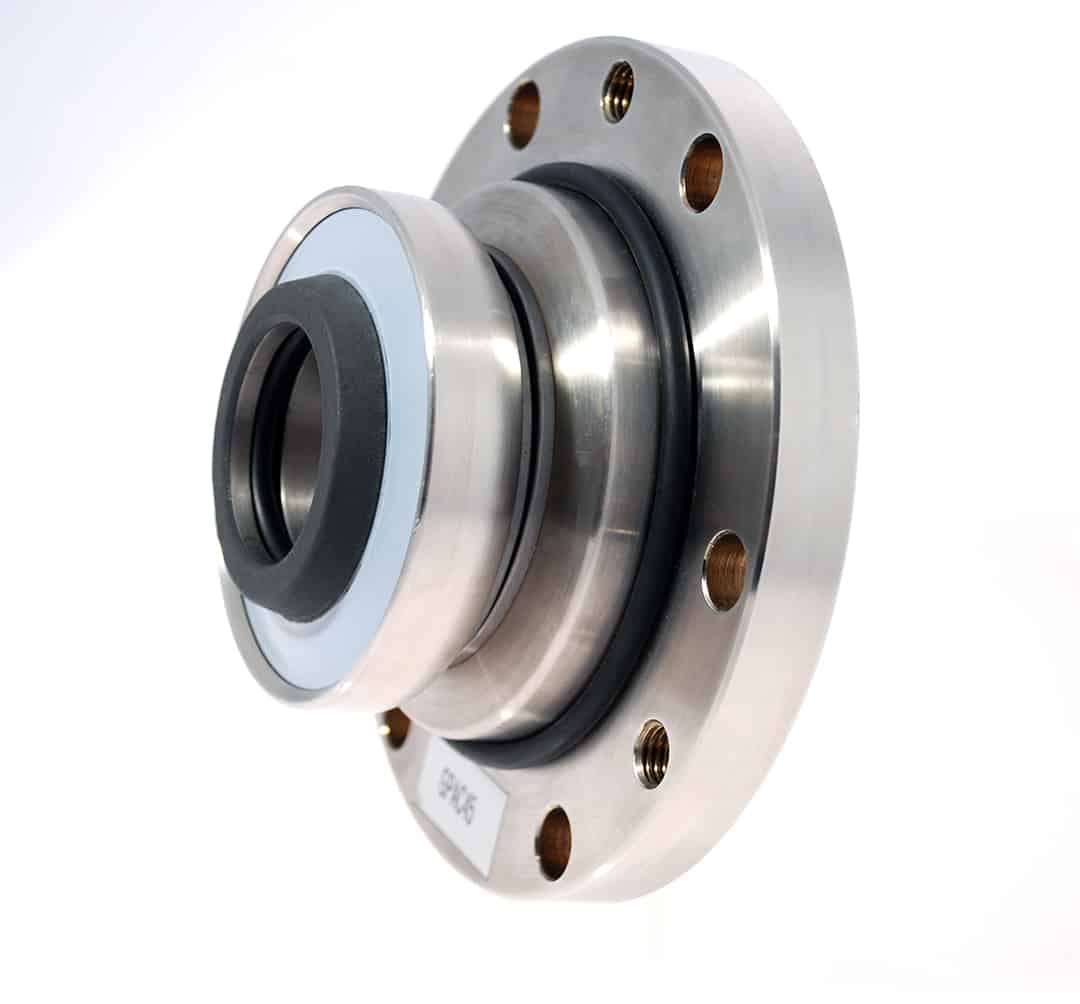

Within the hydrogen sector, sealing technologies play a critical role in maintaining system integrity under demanding conditions. Technetics Group offers an extensive range of sealing solutions, including high-performance static and dynamic seals designed for high-pressure, cryogenic and high-temperature environments. Our approach is analytical and data-driven, prioritizing the balance between the seal’s performance characteristics and the specific requirements of each application in the hydrogen industry. Through meticulous selection and testing, we ensure our clients receive the most effective and reliable sealing solution for their critical projects.

Innovating High-Performance Sealing for Hydrogen Applications

Technetics Group is at the forefront of sealing innovation and is focused on developing solutions that meet the rigorous demands of the hydrogen industry. Our sealing technologies are engineered to withstand extreme pressures and temperatures, offer exceptional resistance to hydrogen embrittlement, and ensure compatibility with hydrogen in its various states. Through continuous research and development, we rigorously test our materials and designs in our state-of-the-art labs to certify their resilience and leak-prevention capabilities. These advancements ensure that our sealing products deliver long-lasting performance and maintain system integrity. This commitment to quality and safety underpins our mission to deliver uncompromised sealing solutions for critical hydrogen applications.

Technetics Group is at the forefront of sealing innovation and is focused on developing solutions that meet the rigorous demands of the hydrogen industry. Our sealing technologies are engineered to withstand extreme pressures and temperatures, offer exceptional resistance to hydrogen embrittlement, and ensure compatibility with hydrogen in its various states. Through continuous research and development, we rigorously test our materials and designs in our state-of-the-art labs to certify their resilience and leak-prevention capabilities. These advancements ensure that our sealing products deliver long-lasting performance and maintain system integrity. This commitment to quality and safety underpins our mission to deliver uncompromised sealing solutions for critical hydrogen applications.

Driving Advancements in Hydrogen Sealing Technology

Technetics Group plays a pivotal role in advancing sealing technology within the hydrogen industry. We are not just observers but active contributors to the development of innovative sealing solutions that address current and future challenges. Our extensive experience is demonstrated through numerous successful installations, where our cutting-edge seals have been applied across various segments of the hydrogen market, including fuel cells, storage and transport systems, and many more. These achievements showcase our ability to overcome complex technical challenges and reinforce our position as leaders in sealing innovation.

Technetics Seals Can Be Found In These Hydrogen Applications:

- Steam Methane Reforming

- Methanation

- Pyrolysis

- Anion Exchange Membrane Electrolyzers (AEM)

- High-Temperature Solid Oxide Fuel Cells

- Small Gas Turbines

- Gas Storage and Handling Systems

- Compressors, Regulators, and Valves

- Sensors

- Carbon Capture Usage and Storage (CCUS)

Commitment to Excellence in Critical Sealing Solutions

Powered by a vision for a sustainable energy future, we leverage our decades of experience to meet the specific sealing needs of today’s hydrogen applications while anticipating the demands of tomorrow. Our portfolio features specialized sealing solutions that guarantee performance, safety, and reliability for our clients’ most crucial projects. Our unique advantages are not merely benefits; they represent our promise that with Technetics Group, your mission-critical applications are secure.

Enhancing Safety, Operational Excellence, and Overpressure Protection in the Hydrogen New Energy Frontier

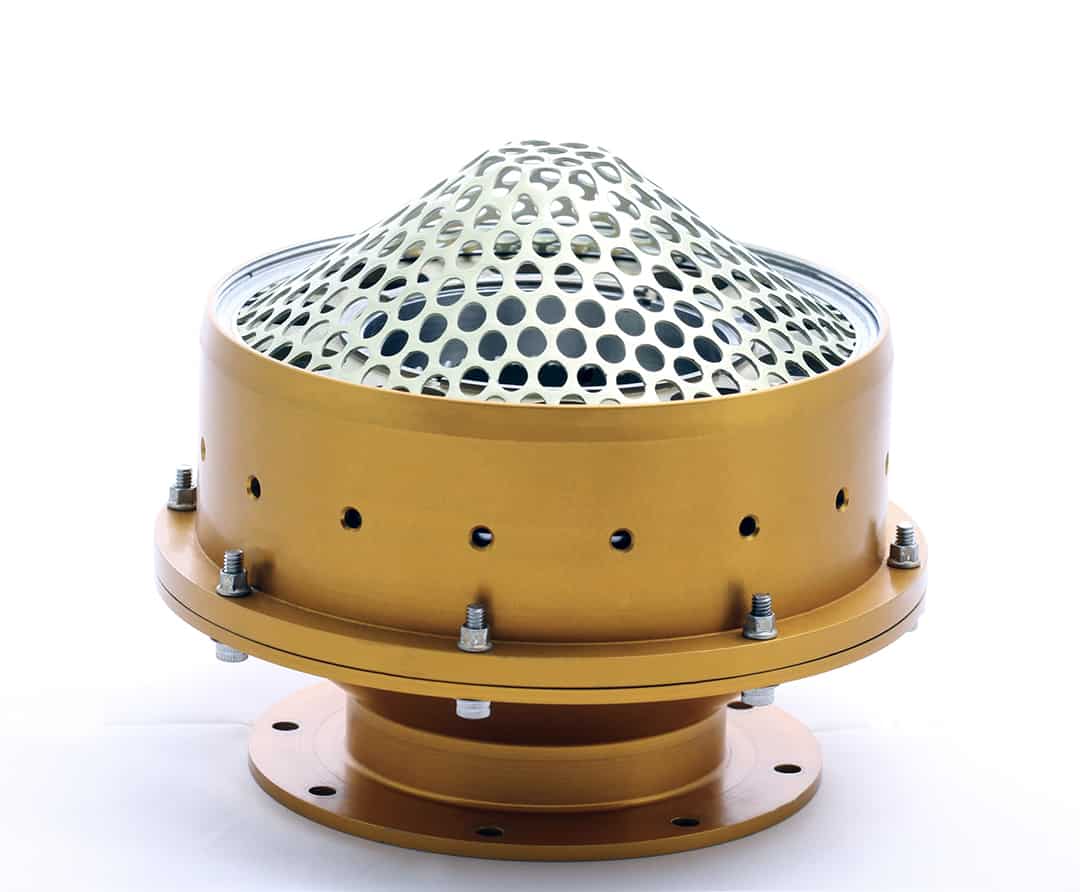

For transportation companies poised to leverage hydrogen fuel cell technology, integrating Technetics Group’s SAFE-SHEAR™ Burst Discs into their safety infrastructure is not just a consideration but a strategic move toward operational excellence. Our burst discs, engineered for the utmost reliability and precision, provide unmatched overpressure protection vital for safely implementing and using hydrogen fuel systems. While promising for environmental sustainability and energy efficiency, transitioning to hydrogen as a fuel source introduces complex safety challenges, particularly in managing the highly pressurized systems required for hydrogen storage and fuel cells.

Pyrolysis technology companies stand at the vanguard of transforming waste into valued commodities such as energy-rich gases, employing processes that necessitate intricate control and management of thermal conditions and pressure. Technetics Group’s SAFE-SHEAR™ burst discs offer an unparalleled advantage in this domain, ensuring the highest safety standards are upheld during pyrolysis. By integrating our burst discs, which are explicitly engineered for precision and reliability, pyrolysis operations can significantly mitigate the risk associated with overpressure scenarios—common in high-temperature reactions. This adoption accentuates a commitment to operational safety and enhances system durability and efficiency.

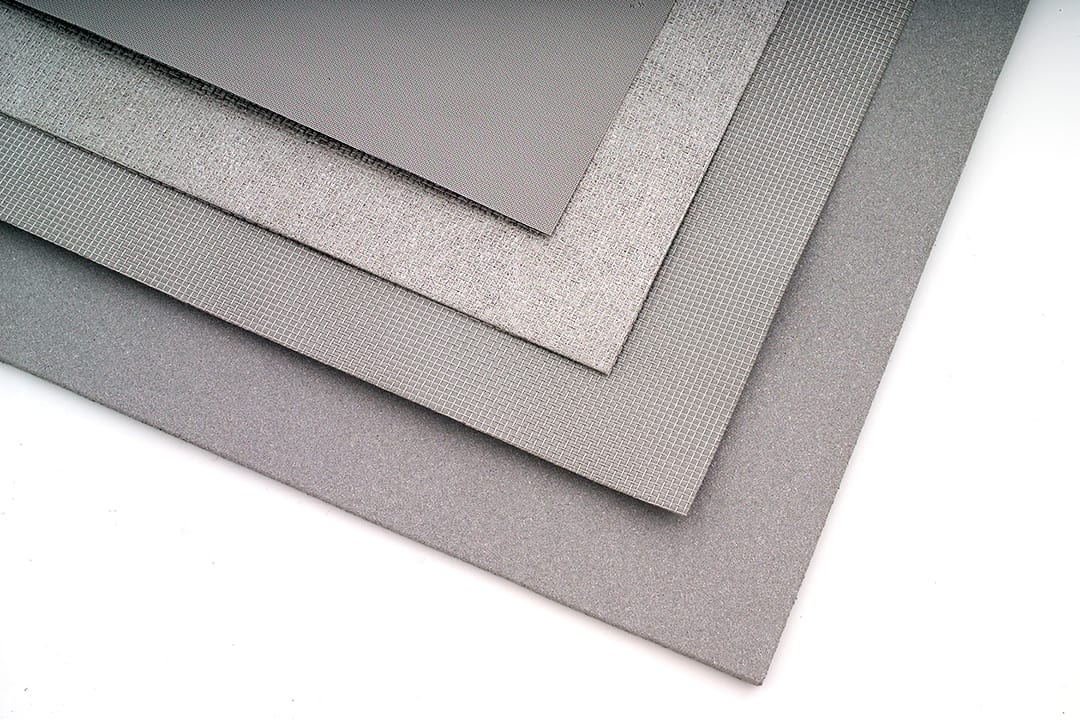

Pioneering the Future of Hydrogen Production Through Innovation and Collaboration

Technetics Group’s dedication to serving the hydrogen industry extends beyond our extensive expertise in sealing technologies. Leveraging over half a century of manufacturing prowess with FELTMETAL™ for the Aerospace sector, Technetics Group is now strategically channeling this unparalleled expertise into the realm of Hydrogen production. Our commitment extends beyond mere application; we are at the frontier of innovation through robust collaborations with academia and key industry stakeholders. By spearheading the development of Porous Transport Layer (PTL) materials, Technetics is dedicated to fulfilling the nuanced requirements of an array of applications. This initiative not only underscores our adaptability and forward-thinking approach but also reinforces our role as a pivotal contributor to advancing green energy solutions.

Our commitment to innovation, paired with our unwavering focus on safety and efficiency, make us a trusted partner in the quest for reliable and safe energy solutions. Our approach is analytical, solution-oriented, and rooted in an assertive pursuit of excellence, ensuring we remain at the cutting edge of sealing technology for high-stakes industries.