-

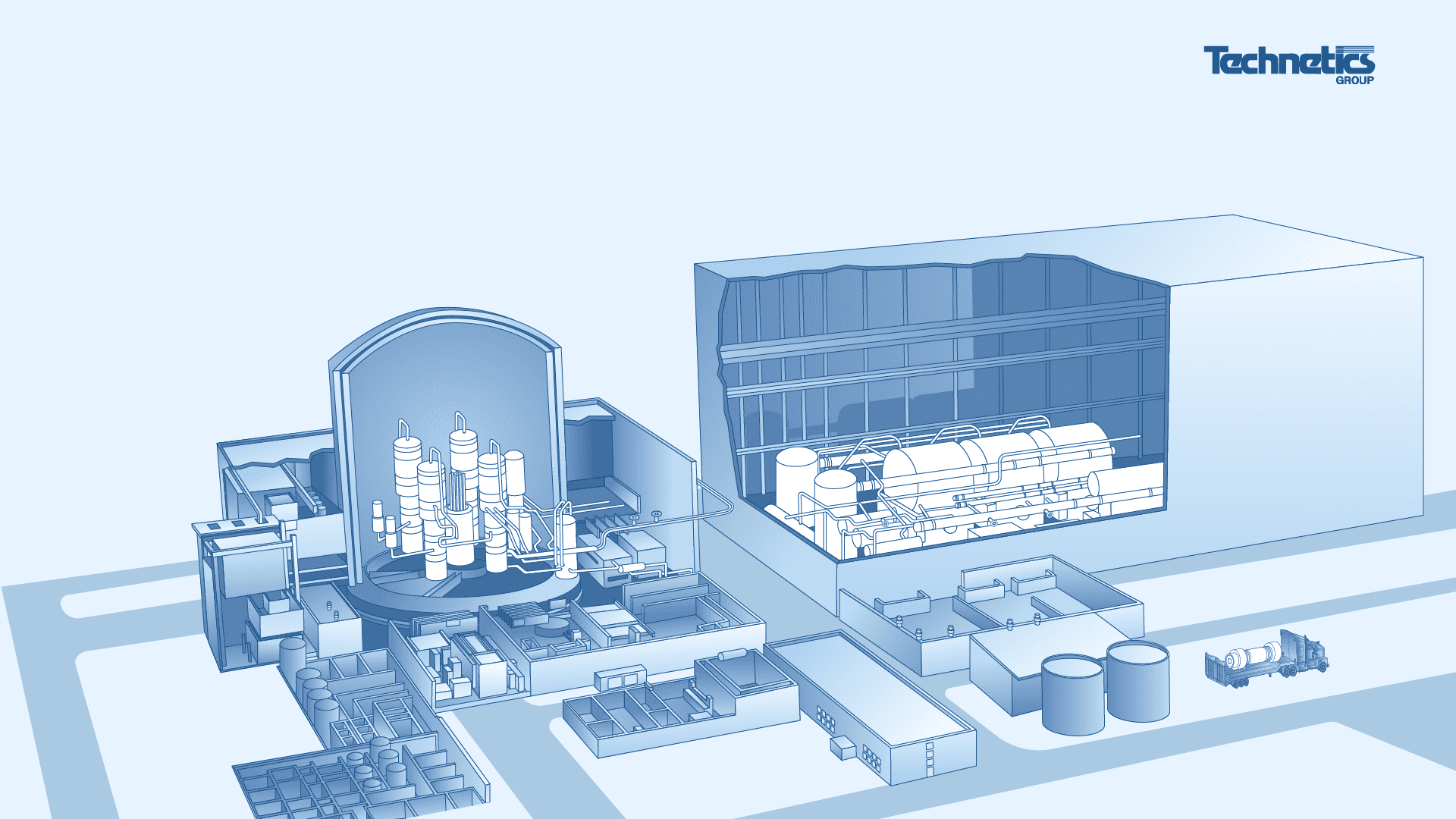

Case StudyEnsuring Clean Power Generation for SwedenOskarshamn 3 was connected to the power grid in 1980. It has been providing approximately 10% of the electricity needs...

Case StudyEnsuring Clean Power Generation for SwedenOskarshamn 3 was connected to the power grid in 1980. It has been providing approximately 10% of the electricity needs... -

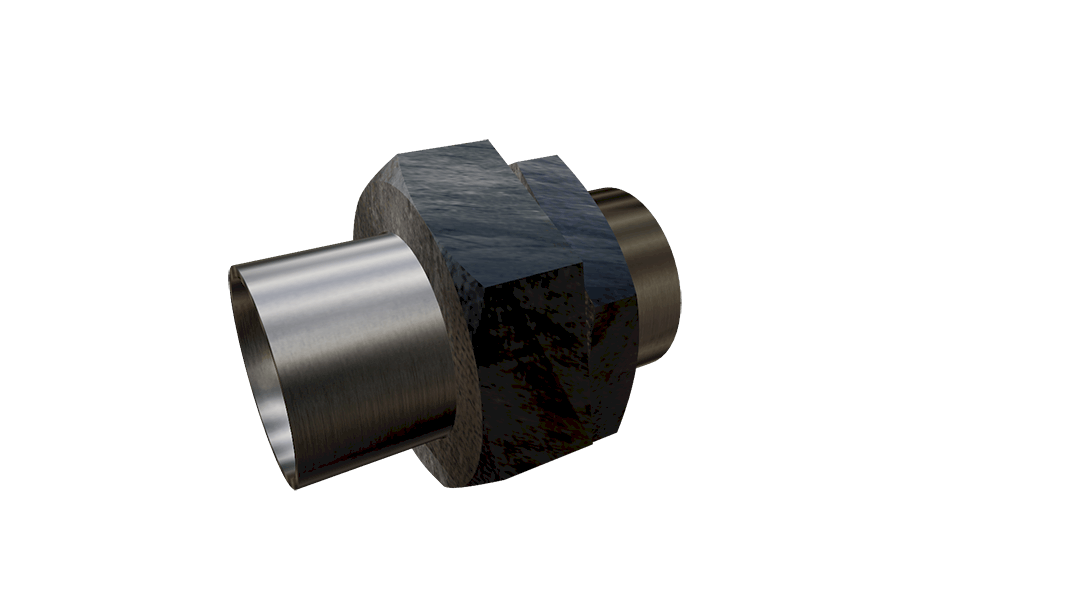

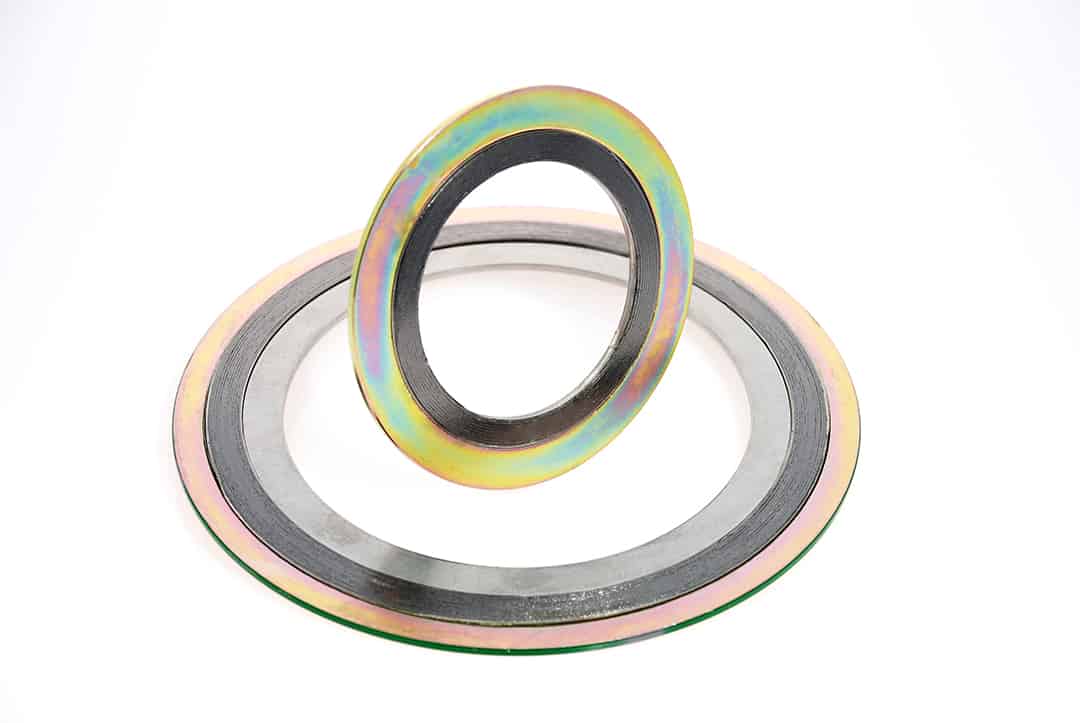

Case StudyCustom Reactor Pressure Vessel (RPV) SealsCustom RPV Seals Help Extend German Nuclear Power Plant’s Operations.

Case StudyCustom Reactor Pressure Vessel (RPV) SealsCustom RPV Seals Help Extend German Nuclear Power Plant’s Operations. -

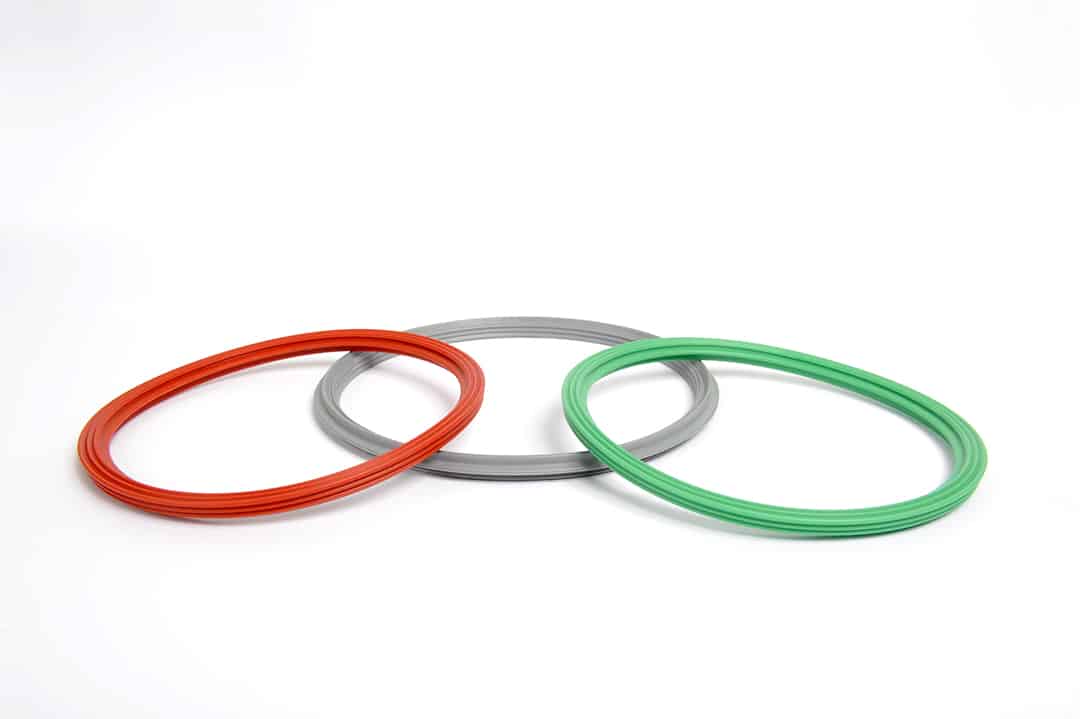

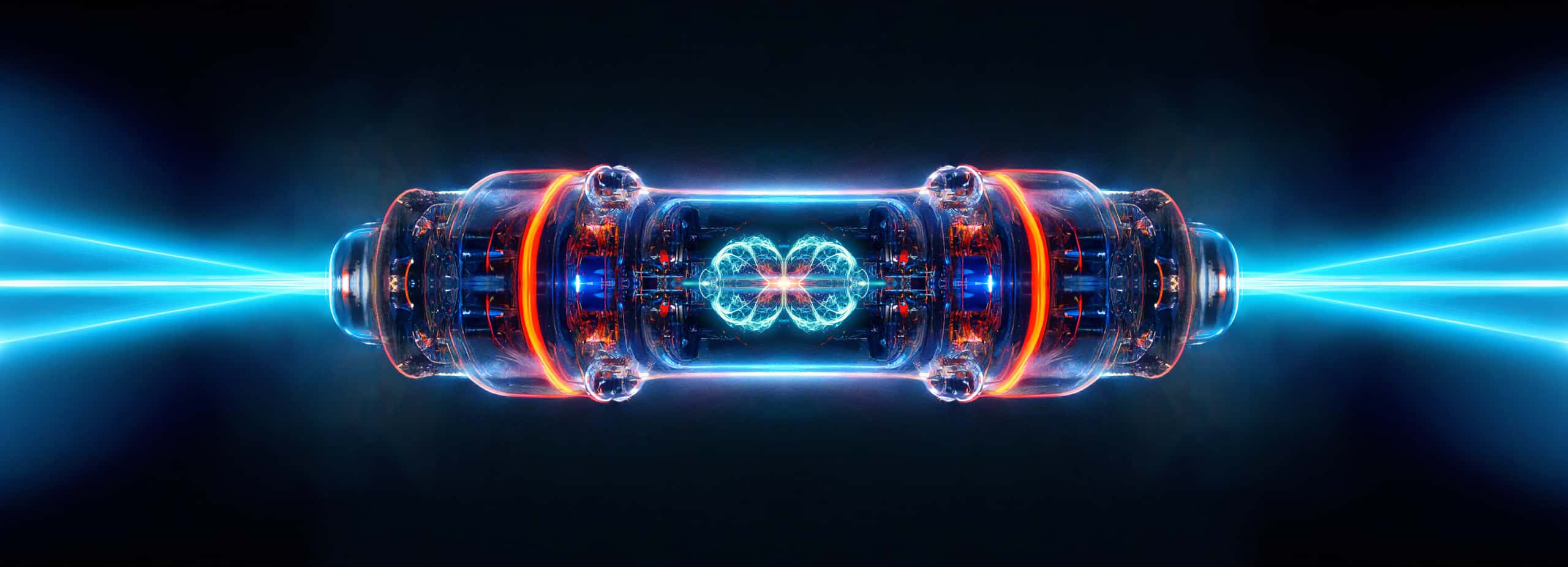

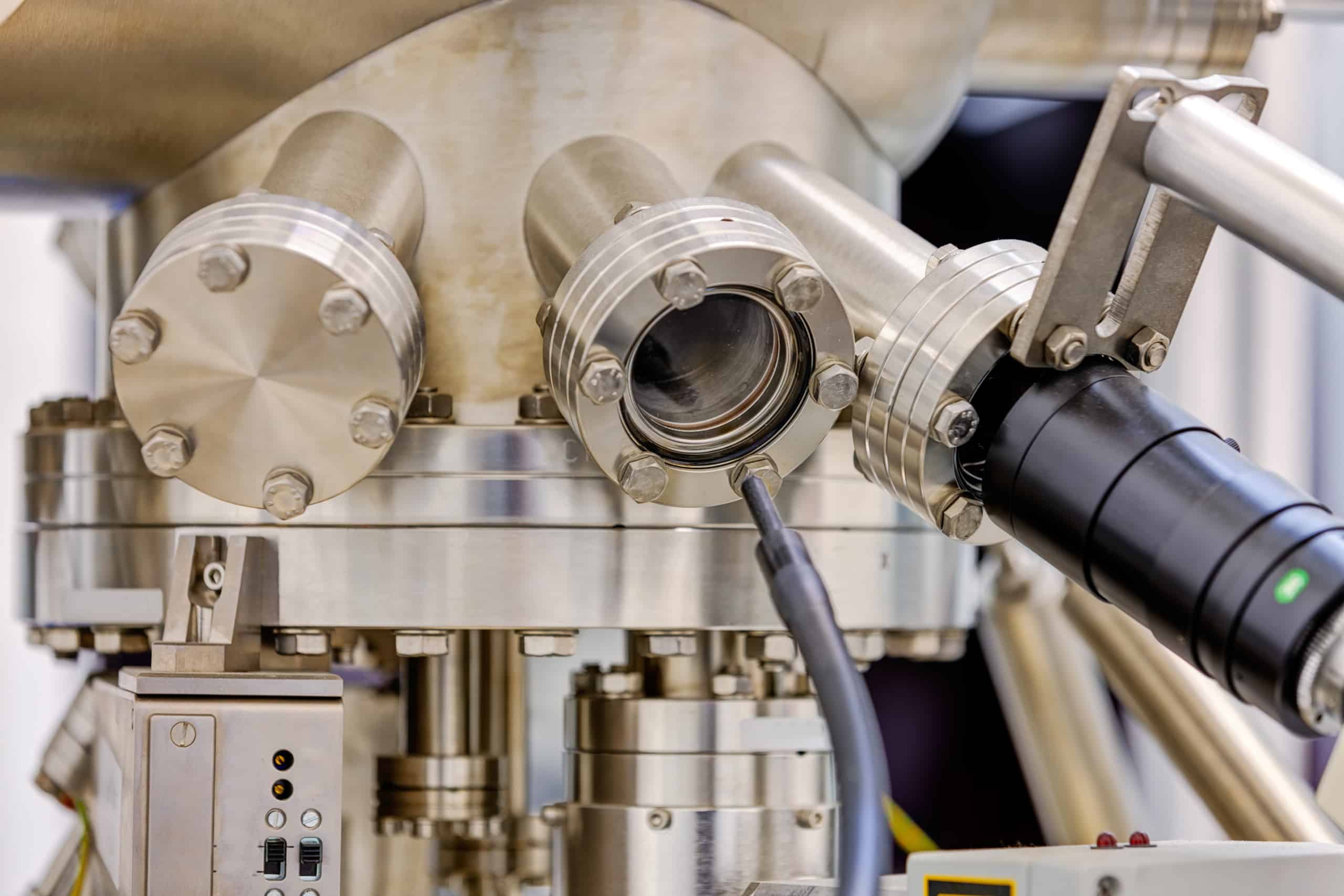

Case StudyDEMO Fusion Reactor Case StudyTechnetics was approached to develop a seal and optimized assembly concept for a maintenance plan to manage the Tokamak port...

Case StudyDEMO Fusion Reactor Case StudyTechnetics was approached to develop a seal and optimized assembly concept for a maintenance plan to manage the Tokamak port... -

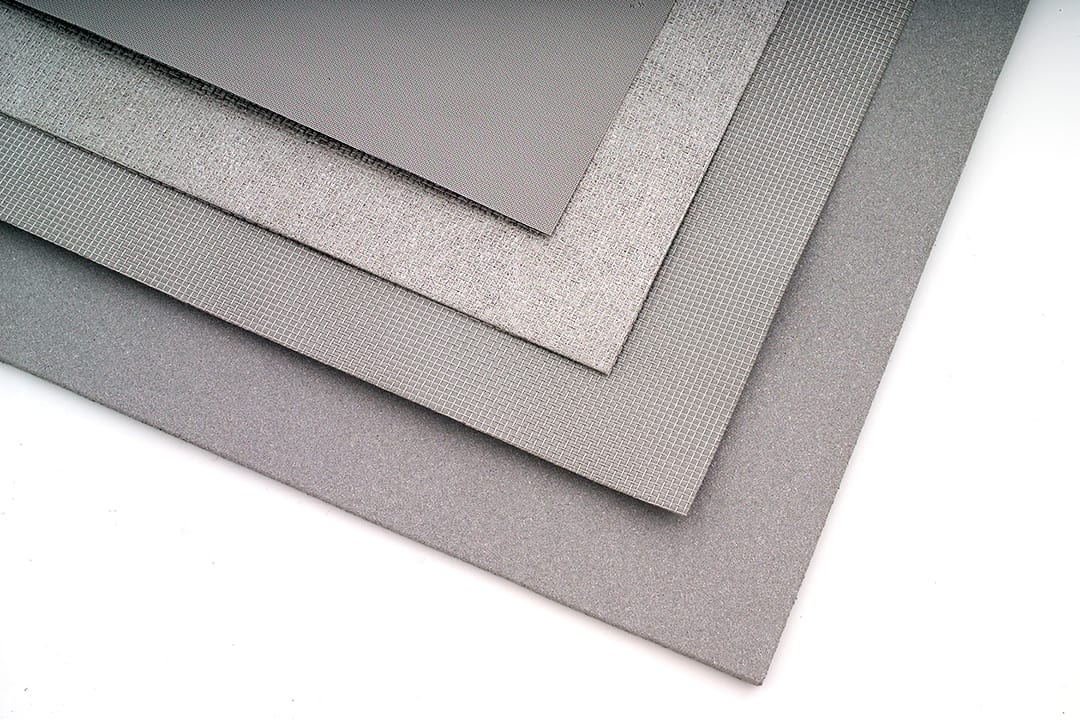

Case StudyEssential Spent Nuclear Fuel StorageLong-time Technetics Group nuclear power partner required a unique gasket and seal solution at a second storage site for spent...

Case StudyEssential Spent Nuclear Fuel StorageLong-time Technetics Group nuclear power partner required a unique gasket and seal solution at a second storage site for spent... -

Case StudyDoosan Case StudyAs a part of the nuclear power plant reactor, the O-ring must operate efficiently within a high-pressure, high-temperature environment and...

Case StudyDoosan Case StudyAs a part of the nuclear power plant reactor, the O-ring must operate efficiently within a high-pressure, high-temperature environment and...

Get the Latest News and Updates

©2024 Technetics Group. All Rights Reserved. Technetics Group is an EnPro Industries, Inc. (NYSE: NPO) Company