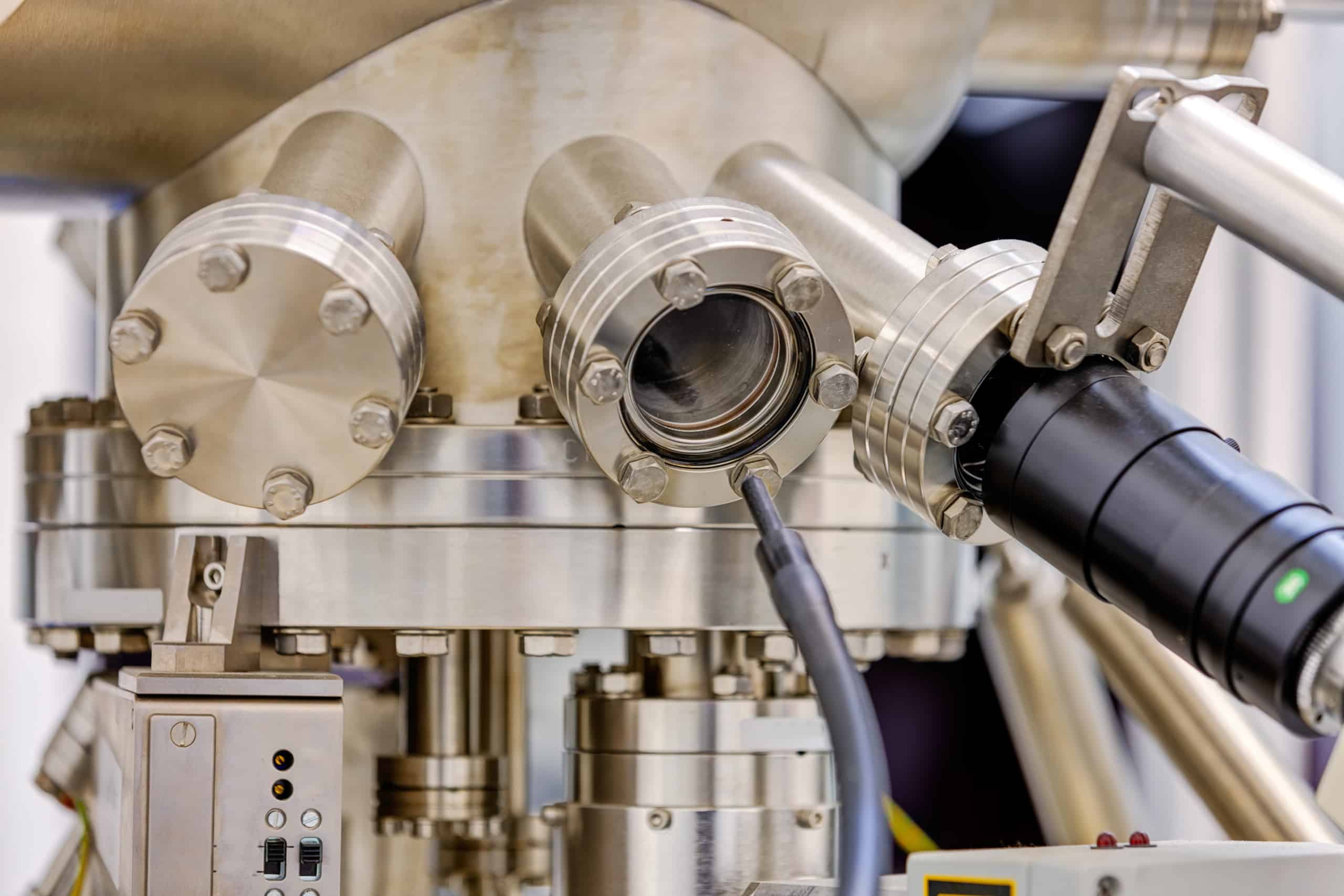

Engineered to Perform Under Pressure — Anywhere

From the depths of the ocean to the heart of a nuclear reactor, Technetics delivers precision-engineered sealing solutions that keep valves operating safely, efficiently and reliably. Whether you’re designing for industrial processing, power generation or extreme environments, our components are built to meet the challenge.

Trusted by Leading Valve Manufacturers Worldwide

Technetics is a preferred partner for OEMs and system integrators across the globe. We design and manufacture critical components for specific valves:

- ¼-turn valves

- Globe, gate and check valves

- Control valves

- Safety-relief valves

Our solutions are tailored to meet the most demanding specifications, ensuring long-term performance and leak-tight integrity in high-pressure, cryogenic to high-temperature and corrosive environments.

Advanced Materials and Technologies

We offer a wide range of high-performance materials and sealing technologies, including:

- Metal seals (including spring-energized HELICOFLEX® seals) – For extreme pressure and temperature resistance

- High-performance ORIGRAF® graphite seals – For chemical or radiation compatibility and exceptional elastic recovery

Each component is rigorously tested and validated to meet or exceed industry standards for safety, durability and performance.

Applications Across Critical Industries

Our valve sealing solutions are trusted in:

- Nuclear Power Plants

- Oil & Gas Exploration, LNG Value Chain

- Chemical Processing

- Aerospace and Defense

- Marine and Subsea Systems

- Research and Big Sciences

Wherever reliability is non-negotiable, Technetics delivers.

Why Choose Technetics?

- Decades of proven expertise in critical sealing applications

- Custom-engineered solutions for your exact valve design

- Global support and responsive engineering collaboration

- Commitment to innovation and continuous improvement

Ready to enhance your valve performance?

Let’s talk about how Technetics can help you reduce downtime, improve safety and extend the life of your systems.