AS1895/7 E-FLEX Seals Brochure

Technetics AS1895/7 E-FLEXTM seals are designed to have low load, high spring back perfor- mance for rigid coupling applications. In service, the E-FLEXTM metal seal is pressure energized by the system which increases the contact stress and further minimizes leakage.

BLADESAFE® Abradable Seals Brochure

Technetics Group’s BLADESAFE® abradable material provides superior clearance control between the blade tip and the casing, mitigating leakage of air flow around the blade and improving overall efficiency as well as life of the engine.

Burst Discs Brochure

Our SAFE-SHEAR™ Burst Discs are designed to set and verify exact rupture pressure in a non-destructive test. This allows systems to safely operate very close to maximum design pressure.

K-Port Seals Brochure

Technetics’ unique K-Port seal design was optimized in-house by our expert engineering staff and validated by dozens of global spaceflight customers over hundreds of successful missions.

Brush Seals Brochure

Technetics Group has been the leader in the production of metal fibers and products incorporating metal fibers and sintered fiber metal materials for over 25 years.

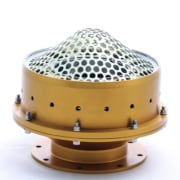

Acoustic Media Brochure

FELTMETALTM media is an engineered, porous material made by the sintering of metal fibers.

UHP and UHV Brochure

Advanced metal sealing solutions for critical UHP/UHV & cryogenic applications.

Abradable Seals Brochure

Abradable seals permit the engine designer to install a rub tolerant material so that the engine operating clearance can be minimized with attendant maximization of engine efficiency.