Critical Solutions for Renewable Energy

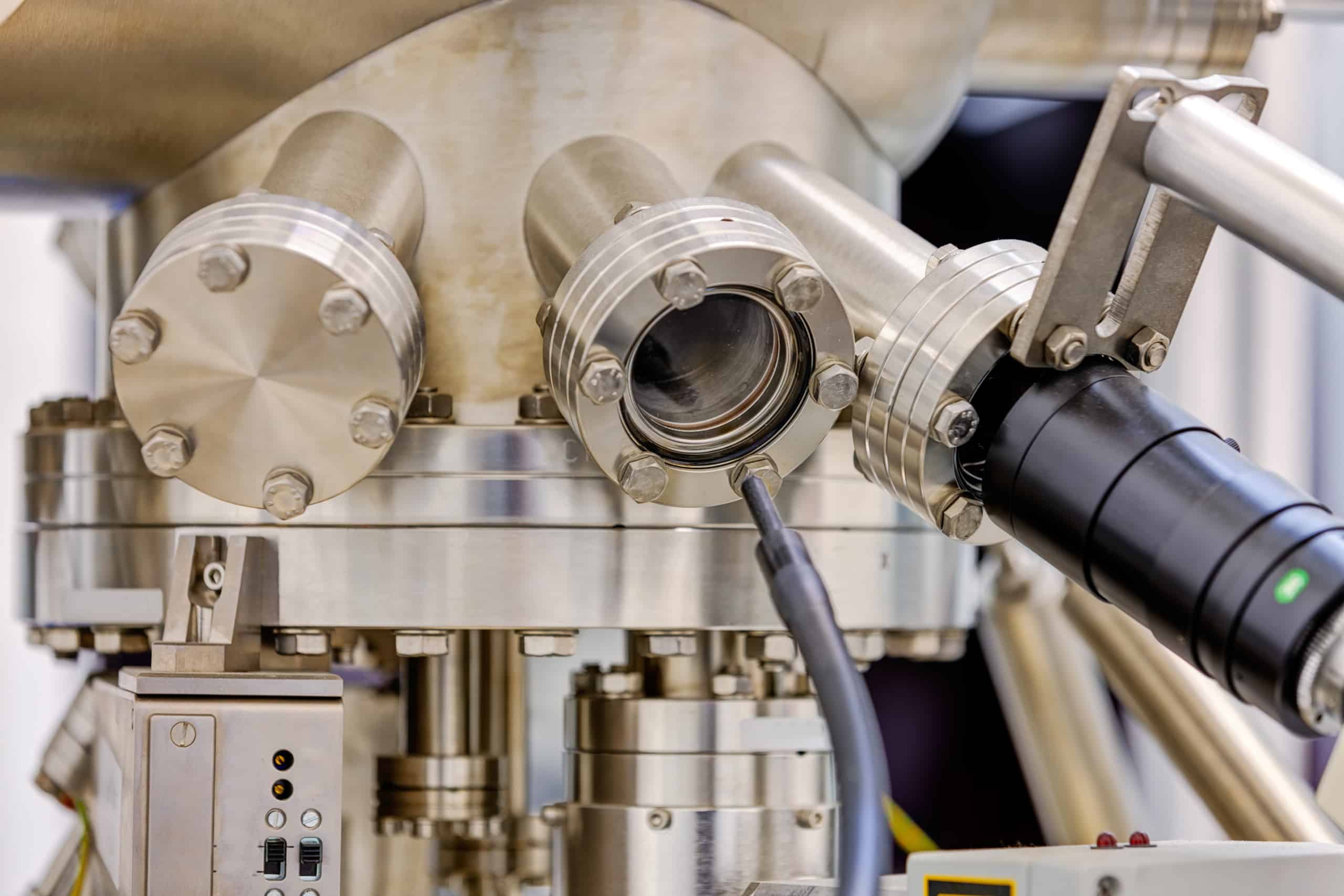

As the demand for renewable energies continues to expand, so does the need for technology to deliver it. Technetics Group powers renewable energy solutions for the handling of gases and media. Our products excel in high-pressure, high-temperature and corrosive environments, improving the reliability of valves, pumps, compressors, tanks and exchangers.

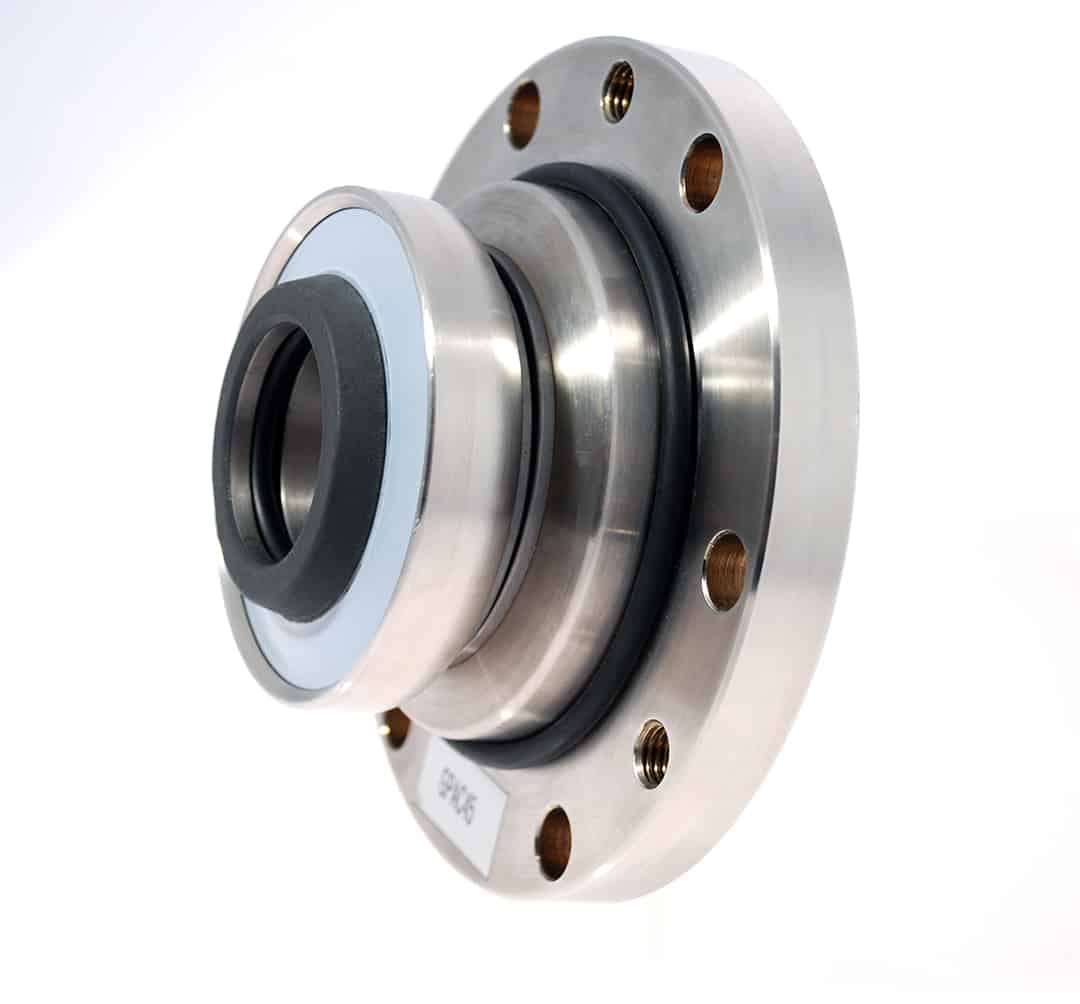

You’ll find Technetics Group parts in thermal solar plants and in every nuclear reactor in the world. Our HELICOFLEX® and C-FLEXTM metal seals provide reliability in applications that demand the highest safety and performance measures, such as in cryogenic conditions, hydrogen storage and distribution processes. Our metal seals are also used in valves for molten salt used to transfer the heat from solar concentration. Where power is produced, Technetics Group seals, including hydrogen seals and mechanical seals, are there.

New Solutions for New Technologies

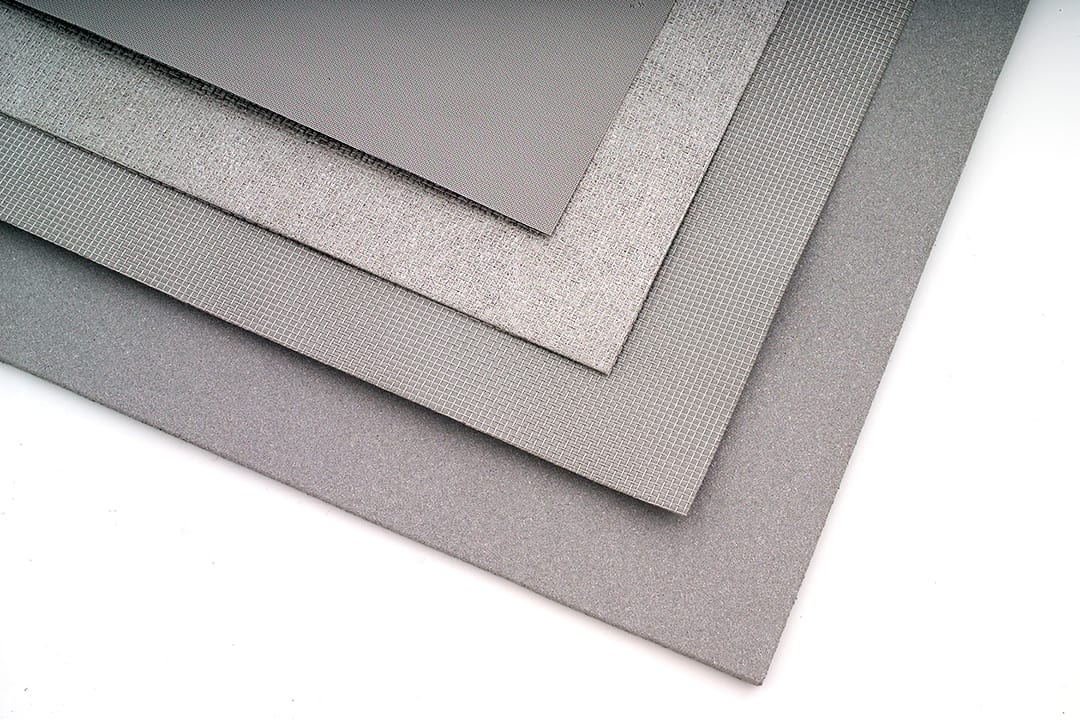

At Technetics Group, we’re leaders in the development of technologies that improve the performance, lifetime and reliability of equipment. Our involvement in the research and development of fuel cells and high temperature electrolysis spans more than 10 years. At our R&D MAESTRAL® lab we work in collaboration with the CEA (French Alternative Energies and Atomic Energy Commission) where, among our many accomplishments, we have pioneered the industrialization of electrolyzer stacks and special sealing systems.

Applications

- Carbon capture

- CCUS (Carbon Capture Usage and Storage)

- Fusion Energy