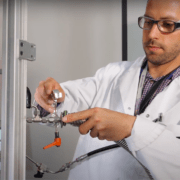

Strength in Science Video

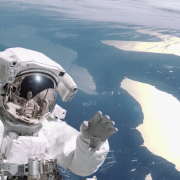

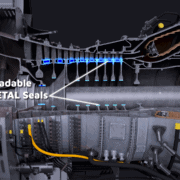

Technetics stands out in its field with a 150-year history of sealing expertise and a team capable of tailoring solutions to meet critical demands, demonstrating adaptability and excellence even when scaling up production during the COVID-19 pandemic. This dedication and problem-solving approach played a vital role in supporting the global effort to combat the pandemic.