Critical Solutions for Semiconductor Manufacturing

In the semiconductor industry keeping pace with the rapidly evolving market is essential. You need the confidence you only get by working with partners that are responsive to your innovations, provide on-time delivery, and offer prices that will keep you profitable. In each of these cases, Technetics Group delivers.

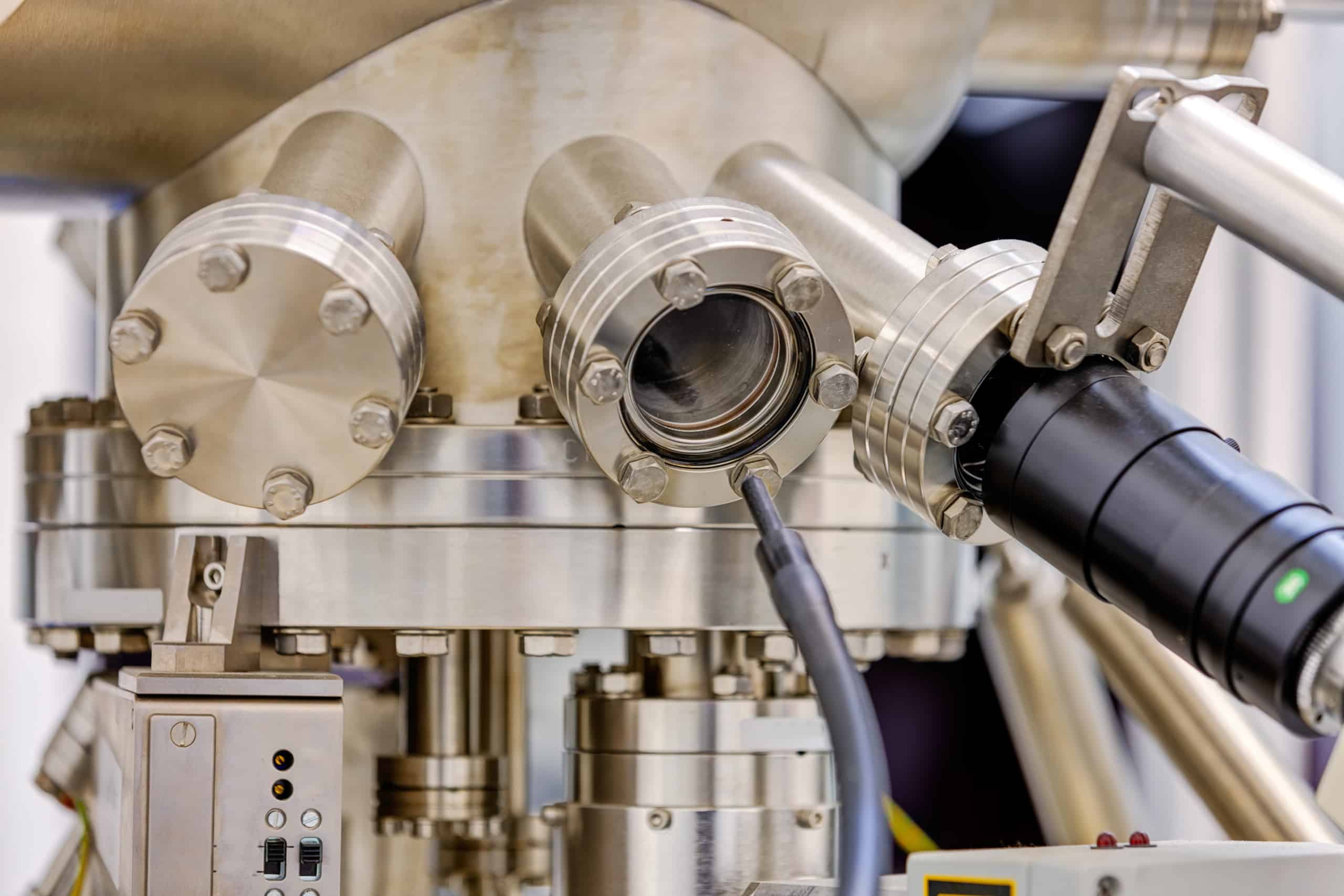

50+ Years of Design

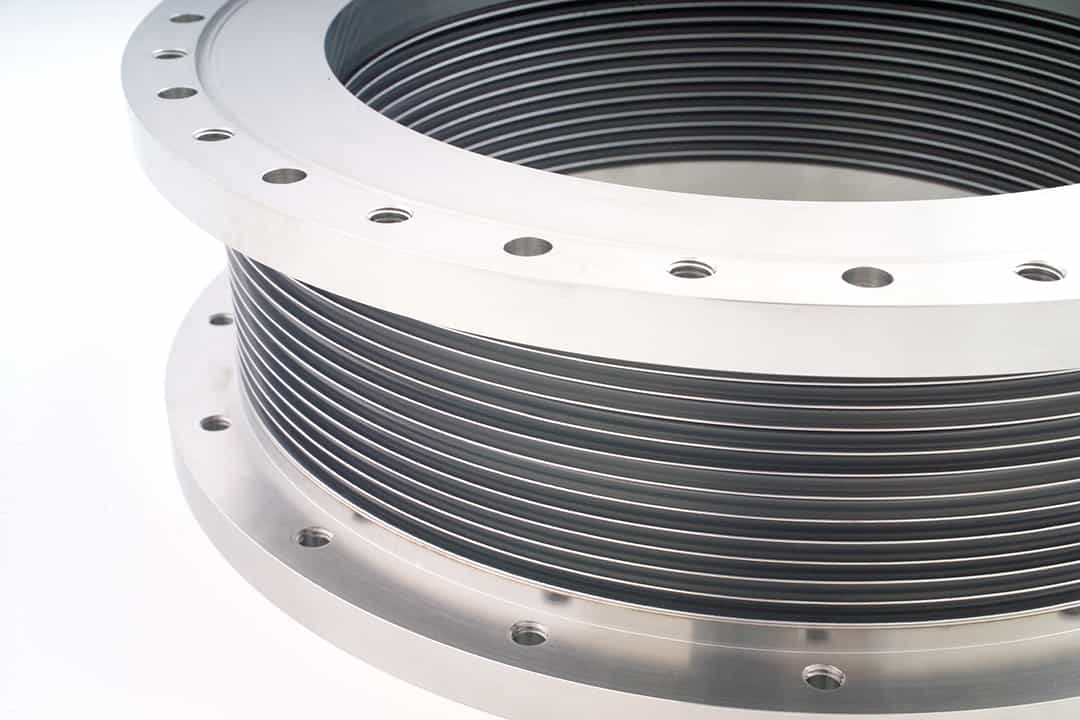

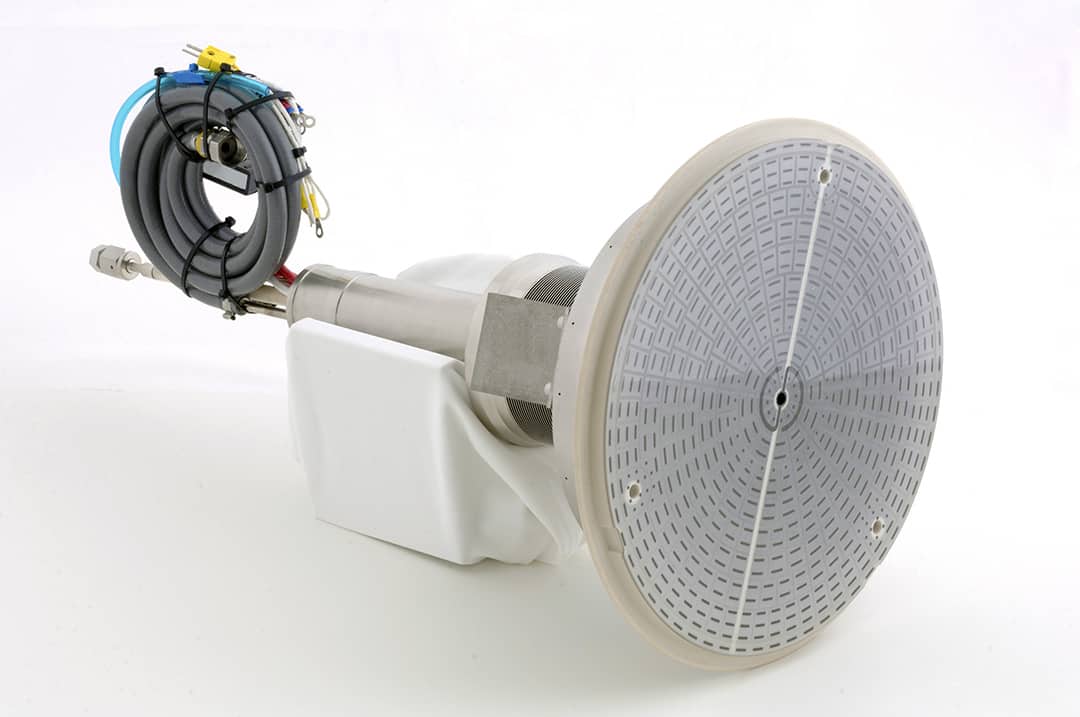

Technetics Group has more than 50 years of bellows design knowledge with top-down operational excellence. We have produced over 500,000 bellows and over 12,000 new and refurbished electrostatic chuck pedestals. We also design and manufacture complex front-end wafer-process assemblies including heater pedestals, wafer and pedestal lift assemblies and electrostatic chucks (ESCs) that can be improved with advanced coatings.

Due to our quick-turn prototyping, on-time delivery and strict process control we are a preferred supplier to leading equipment OEMs and fabs. Our custom OEM solutions provide the highest quality, competitive prices, and a slew of additional advantages including:

- Integration and testing in certified, on-site clean rooms

- Commercial solutions including consignment programs

- Competitive lead times

- “Design for manufacturability” mindset

- Customer-collaborative environment

- Testing, analytical, failure analysis capabilities

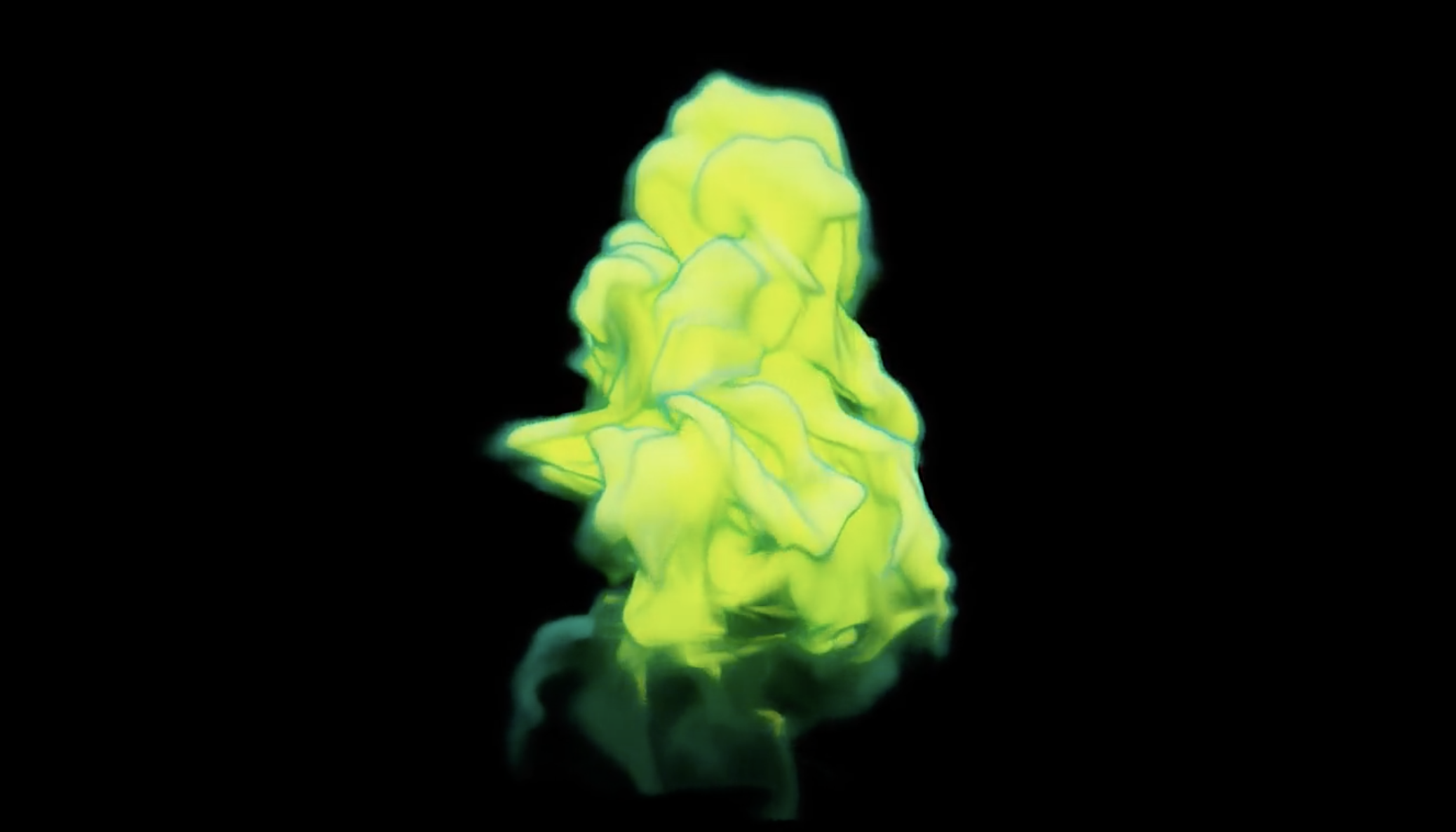

Advanced Coating and Chemical Cleaning

Technetics Group’s novel thin film coatings provide a fully dense, non-porous, etch resistant uniform coating that can be used to extend the life of process chamber components, reduce particle levels within a chamber, or “cap and seal” electrostatic chucks to provide leakage current control. With full chemical cleaning and analytical test capabilities we can provide solutions for your brand-new process chamber components, or refurbish existing components, bringing them back to a brand-new state all under one roof.