Critical Solutions for the Oil & Gas Industry

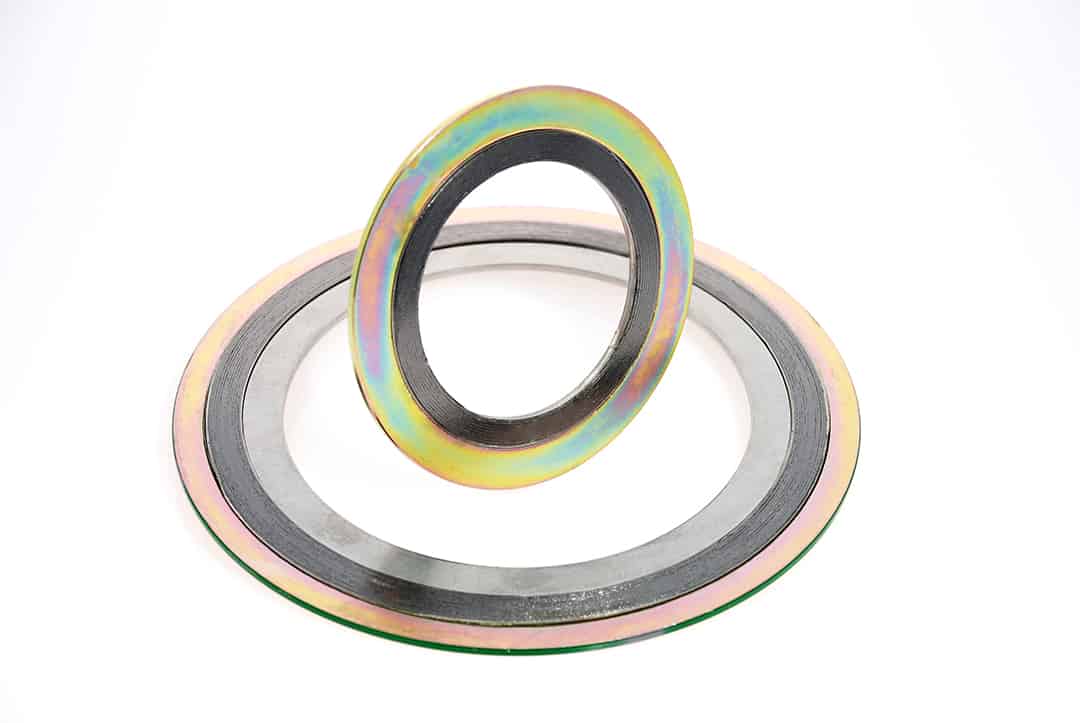

Sealing is critical in the oil and gas industry—more than nearly any other industry. That’s because better sealing protects the environment, enhances performance, and provides the unquestioned confidence you need when it matters most. With over five decades of experience working with oil and gas component manufacturing, Technetics Group gives you that confidence. Our products are engineered for unrivaled quality and reliability. From exploring to producing, transporting to refining, Technetics Group offers performance that is built to last.

“I recently performed a prototype test on the 24” valve design. The test required 1000 full differential pressure cycles, and we did not see any leakages or concerns when we performed the tear-down. We have only had two failures that I’m aware of, but they were both on our end. We have not heard of any field issues. Just wanted to share some positive feedback with y’all.”

Senior Valve EngineerLarge Oilfield Valve Manufacturer

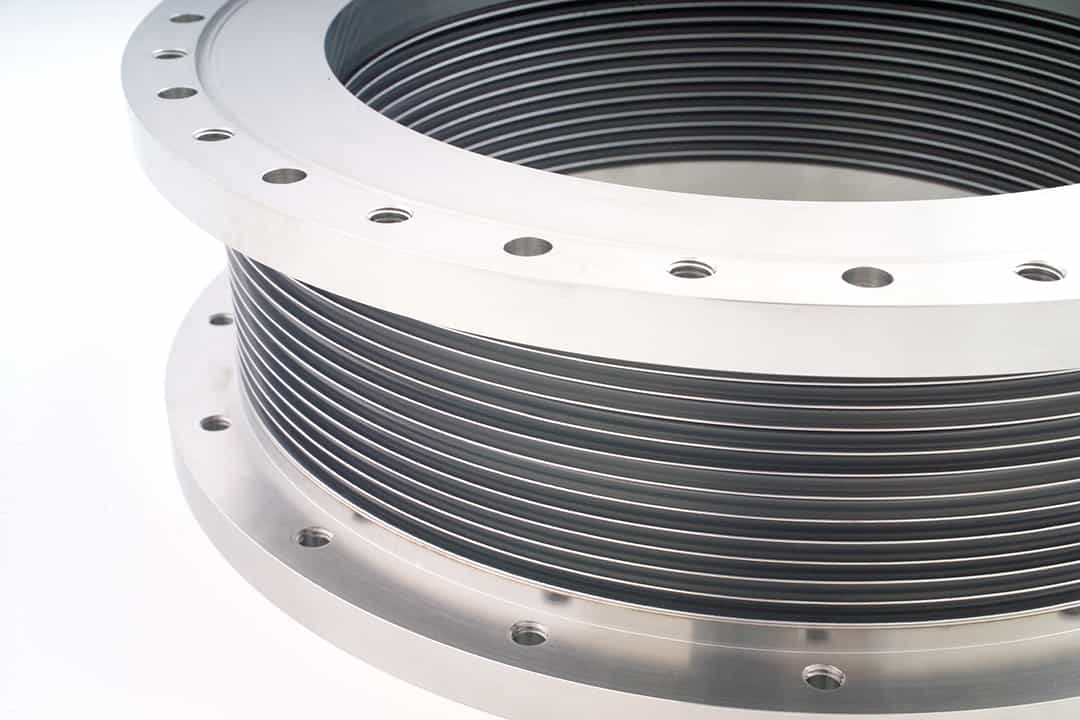

Look for our precision components, polymers and BELFAB® bellows assemblies, where customized precision in hazardous conditions matters, including down-hole drilling applications, logging while drilling (LWD), measurement while drilling (MWD), blowout preventers, electric submersible pumps (ESPs), artificial lifts and fracking—just to name a few.

Related Products

Case Studies

-

Case StudyEnsuring Clean Power Generation for SwedenTechnetics custom-designed 260” RPV O-FLEX metal O-ring spare seals are made from high-strength Alloy 718 tubing — offering maximum strength,...

Case StudyEnsuring Clean Power Generation for SwedenTechnetics custom-designed 260” RPV O-FLEX metal O-ring spare seals are made from high-strength Alloy 718 tubing — offering maximum strength,... -

Case StudyCustom Reactor Pressure Vessel (RPV) SealsCustom RPV Seals Help Extend German Nuclear Power Plant’s Operations.

Case StudyCustom Reactor Pressure Vessel (RPV) SealsCustom RPV Seals Help Extend German Nuclear Power Plant’s Operations. -

Case StudyDoosan Case StudyDoosan selected Technetics RPV O-ring as the ideal solution for their high-pressure, high-temperature application because failure is not an option.

Case StudyDoosan Case StudyDoosan selected Technetics RPV O-ring as the ideal solution for their high-pressure, high-temperature application because failure is not an option. -

Case StudyEssential Spent Nuclear Fuel Storage RequirementsLong-time Technetics Nuclear Power Partner Required Unique Gasket and Seal Solution at Second Storage Site for Spent Nuclear Fuel Elements

Case StudyEssential Spent Nuclear Fuel Storage RequirementsLong-time Technetics Nuclear Power Partner Required Unique Gasket and Seal Solution at Second Storage Site for Spent Nuclear Fuel Elements -

Case StudySemiconductor Vacuum Pump HELICOFLEX® Case StudyIndustry-leading experts in vacuum and abatement in Semiconductor Manufacturing collaborate with Technetics Group to develop efficient solutions that set new...

Case StudySemiconductor Vacuum Pump HELICOFLEX® Case StudyIndustry-leading experts in vacuum and abatement in Semiconductor Manufacturing collaborate with Technetics Group to develop efficient solutions that set new... -

Case StudySemiconductor Manufacturing Chemical Delivery Case StudyThe semiconductor manufacturing process requires the use of highly toxic chemicals. The chemical plant providing these chemicals needed a vacuum-tight...

Case StudySemiconductor Manufacturing Chemical Delivery Case StudyThe semiconductor manufacturing process requires the use of highly toxic chemicals. The chemical plant providing these chemicals needed a vacuum-tight... -

Case StudyDEMO Fusion Reactor Case StudyA client approached Technetics to develop a seal and optimized assembly concept for a maintenance plan to manage the Tokamak...

Case StudyDEMO Fusion Reactor Case StudyA client approached Technetics to develop a seal and optimized assembly concept for a maintenance plan to manage the Tokamak... -

Case StudyAPU Mechanical Seals Case StudyA sealing problem causing noxious cabin odor made airline passengers very unhappy. The manufacturer needed a reliable solution. Technetics provided...

Case StudyAPU Mechanical Seals Case StudyA sealing problem causing noxious cabin odor made airline passengers very unhappy. The manufacturer needed a reliable solution. Technetics provided... -

Case StudySupporting Space Flight History with the Space Launch...Supporting Space Flight History with the Space Launch System Technetics Group is a proud supplier to NASA, Boeing and Aerojet Rocketdyne,...

Case StudySupporting Space Flight History with the Space Launch...Supporting Space Flight History with the Space Launch System Technetics Group is a proud supplier to NASA, Boeing and Aerojet Rocketdyne,... -

Case StudyAlternate Energy Case StudyAlternate Energy Solutions Conquerers Sealing Challenges with HELICOFLEX® Customized HELICOFLEX® Provides the Ideal Seal Alternate Energy Solutions, a division of downhole plug...

Case StudyAlternate Energy Case StudyAlternate Energy Solutions Conquerers Sealing Challenges with HELICOFLEX® Customized HELICOFLEX® Provides the Ideal Seal Alternate Energy Solutions, a division of downhole plug... -

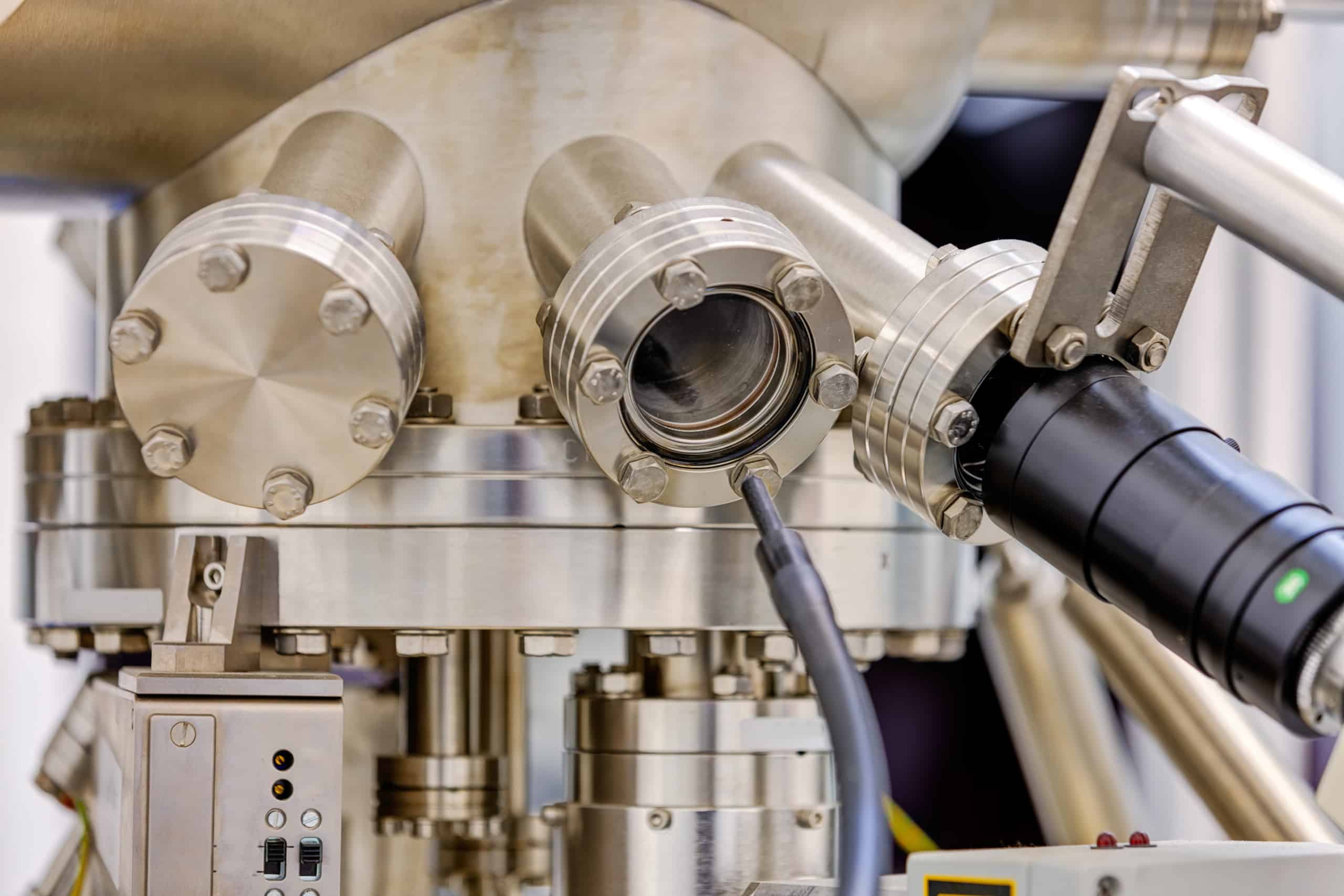

Case StudyTechnetics Provides Optimal Sealing SolutionAs a part of its Advanced Light Source Upgrade, Berkley Lab needed a sealing solution for its accumulator ring. Technetics...

Case StudyTechnetics Provides Optimal Sealing SolutionAs a part of its Advanced Light Source Upgrade, Berkley Lab needed a sealing solution for its accumulator ring. Technetics... -

Case StudyQualiseal® - Circumferential Seal Application: Military AircraftCircumferential Seal Application: Military Aircraft The control valve in a military aircraft had a controlled gap circumferential seal with a carbon...

Case StudyQualiseal® - Circumferential Seal Application: Military AircraftCircumferential Seal Application: Military Aircraft The control valve in a military aircraft had a controlled gap circumferential seal with a carbon... -

Case StudyQualiseal® - Mating Ring Solution: Hydraulic PumpMating Ring Solution: Hydraulic Pump An aerospace OEM historically purchased an inexpensive mating ring to pair with a precision carbon face...

Case StudyQualiseal® - Mating Ring Solution: Hydraulic PumpMating Ring Solution: Hydraulic Pump An aerospace OEM historically purchased an inexpensive mating ring to pair with a precision carbon face... -

Case StudyQualiseal® - Contacting Face Seal Application: Aircraft EngineContacting Face Seal Application: Aircraft Engine The main shaft in a commercial aircraft engine had an existing carbon face seal experiencing...

Case StudyQualiseal® - Contacting Face Seal Application: Aircraft EngineContacting Face Seal Application: Aircraft Engine The main shaft in a commercial aircraft engine had an existing carbon face seal experiencing... -

Case StudyQualiseal® - Metal Bellows Seal Application: Fuel PumpMetal Bellows Seal Application: Fuel Pump Background The pump for a commercial aircraft had an existing carbon face seal experiencing high leakage...

Case StudyQualiseal® - Metal Bellows Seal Application: Fuel PumpMetal Bellows Seal Application: Fuel Pump Background The pump for a commercial aircraft had an existing carbon face seal experiencing high leakage... -

Case StudyNon-Contacting Gearbox SealNon-Contacting Face Seal Application: Gearbox The Gearbox in a commercial aircraft engine had multiple locations with carbon face seals experiencing high...

Case StudyNon-Contacting Gearbox SealNon-Contacting Face Seal Application: Gearbox The Gearbox in a commercial aircraft engine had multiple locations with carbon face seals experiencing high... -

Case StudySealing Solutions for Subsea Systems in the North...Sealing Solutions for Subsea Systems in the North Sea The Aasgard oil and gas field in the North Sea has been...

Case StudySealing Solutions for Subsea Systems in the North...Sealing Solutions for Subsea Systems in the North Sea The Aasgard oil and gas field in the North Sea has been... -

Case StudySpeeding Up The ProcessSpeeding Up The Process How Technetics Developed New Hydrodynamic Seals in Just Thirteen Weeks Technetics was contacted by a well-known global aerospace...

Case StudySpeeding Up The ProcessSpeeding Up The Process How Technetics Developed New Hydrodynamic Seals in Just Thirteen Weeks Technetics was contacted by a well-known global aerospace... -

Case StudyLaunching the mission to MarsLaunching the mission to Mars NASA recognizes Technetics Group’s contribution to history-making mission NASA’s journey to Mars, which will culminate in humans...

Case StudyLaunching the mission to MarsLaunching the mission to Mars NASA recognizes Technetics Group’s contribution to history-making mission NASA’s journey to Mars, which will culminate in humans...