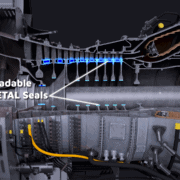

3D Tour of Sealing Solutions and Acoustic Attenuation on Commercial Aircraft

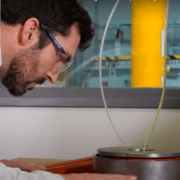

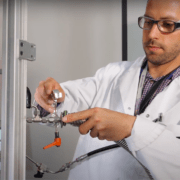

Deep inside every aircraft metal seals, mechanical seals, brush seals, and elastomeric seals are working to provide safety and efficiency. Take a look inside a turbine engine to learn how these seals play a critical role in the engine’s performance. In this video, you will also see where our patented acoustic Feltmetal® is specified in the auxiliary power unit to dampen engine noise for passenger comfort and regulation compliance. Since the 1950s, Technetics Group has been engineering aerospace components including abradable Feltmetal® seals, brush seals, face seals, circumferential seals, elastomer seals, static metal seals, acoustic media, burst discs, edge-welded metal bellows, and accumulators.